Accumulation type trolley conveyor impulse sender

A technology of hanging conveyor and numbering device, which is applied to conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of high cost, difficult popularization and application, complex structure, etc., and achieves simple production and reduced production process. , the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

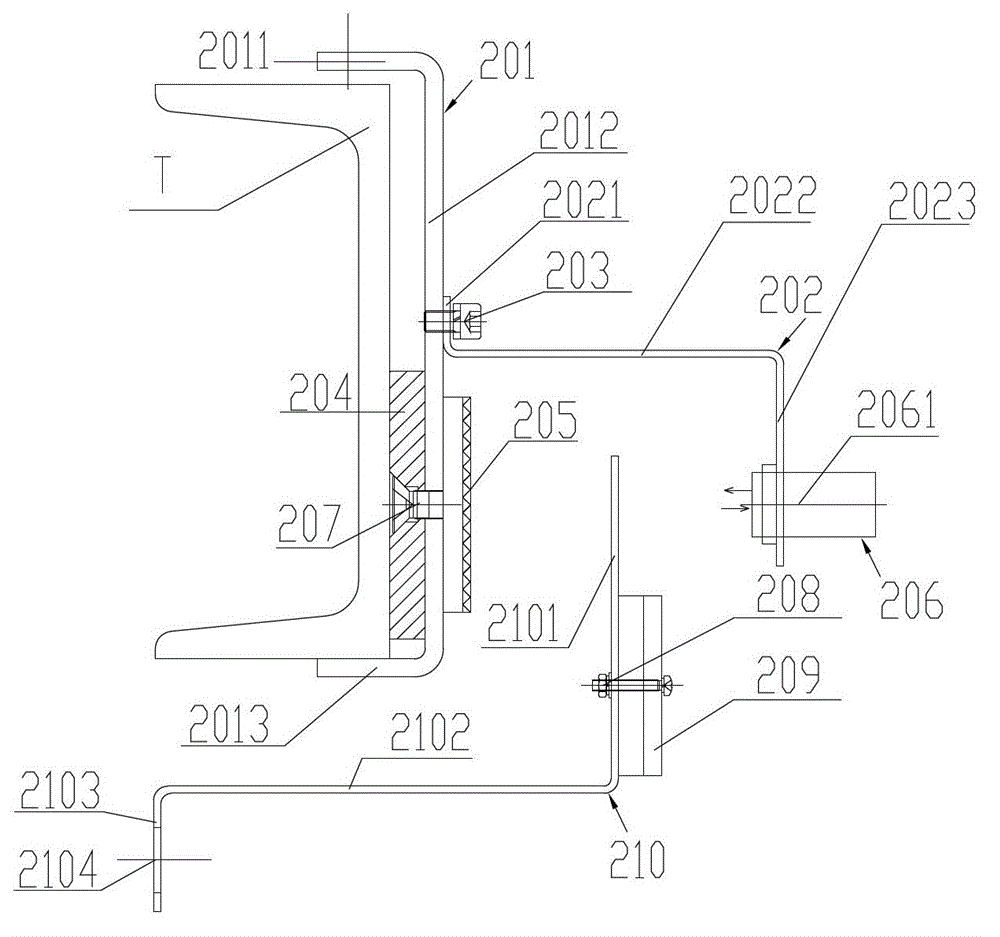

[0025] see Figure 2a , Figure 2b , represents the mechanical principle structure of a preferred embodiment of the signal generator of the accumulation type suspension conveyor of the present invention. This embodiment provides a kind of manufacturing simple, reliable in use, easy to adjust the positive and negative accumulative type suspension conveyer number issuer, it comprises photoelectric switch 206 and issue plate 210: photoelectric switch 206 is installed on the carrying track T, issue plate 210 installed in the cargo trolley ( Figure 2a , Figure 2b not shown), wherein the signaling board 210 can run into the transmitter-receiver optical path of the photoelectric switch 206, so as to trigger the photoelectric switch 206 to send a switching signal, which is transmitted to the In the logic control system PLC of the product-free suspension conveyor, the running route of the cargo trolley is finally determined by controlling the action of the switch tongue (not shown...

Embodiment 2

[0040] Different from Embodiment 1, this embodiment adopts other forms of photoelectric switches 206, such as through-beam photoelectric switches, diffuse reflection photoelectric switches, mirror emission photoelectric switches, optical fiber photoelectric switches, etc. It is sufficient to be able to cut into the optical path between the transmitter and the receiver.

[0041] For example, simply adopting the through-beam photoelectric switch 206 can well meet the requirements of the present invention. The emitter and the reflector of the through-beam photoelectric switch are structurally separated from each other, and the two are relatively arranged. Correspondingly, the reflector 205 is omitted. When the signaling board 210 cuts between the transmitter and the receiver, it blocks the optical paths of the two and causes the state of the photoelectric switch 206 to change, thereby triggering the detection circuit of the photoelectric switch 206 to send a switching signal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com