Ocean platform crane with buggy luffing mechanism

An offshore platform and luffing mechanism technology, applied in cranes and other directions, can solve the problems of uneven luffing speed, consumption of driving power, low luffing efficiency, etc., and achieve fast luffing speed, low driving power and high working efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

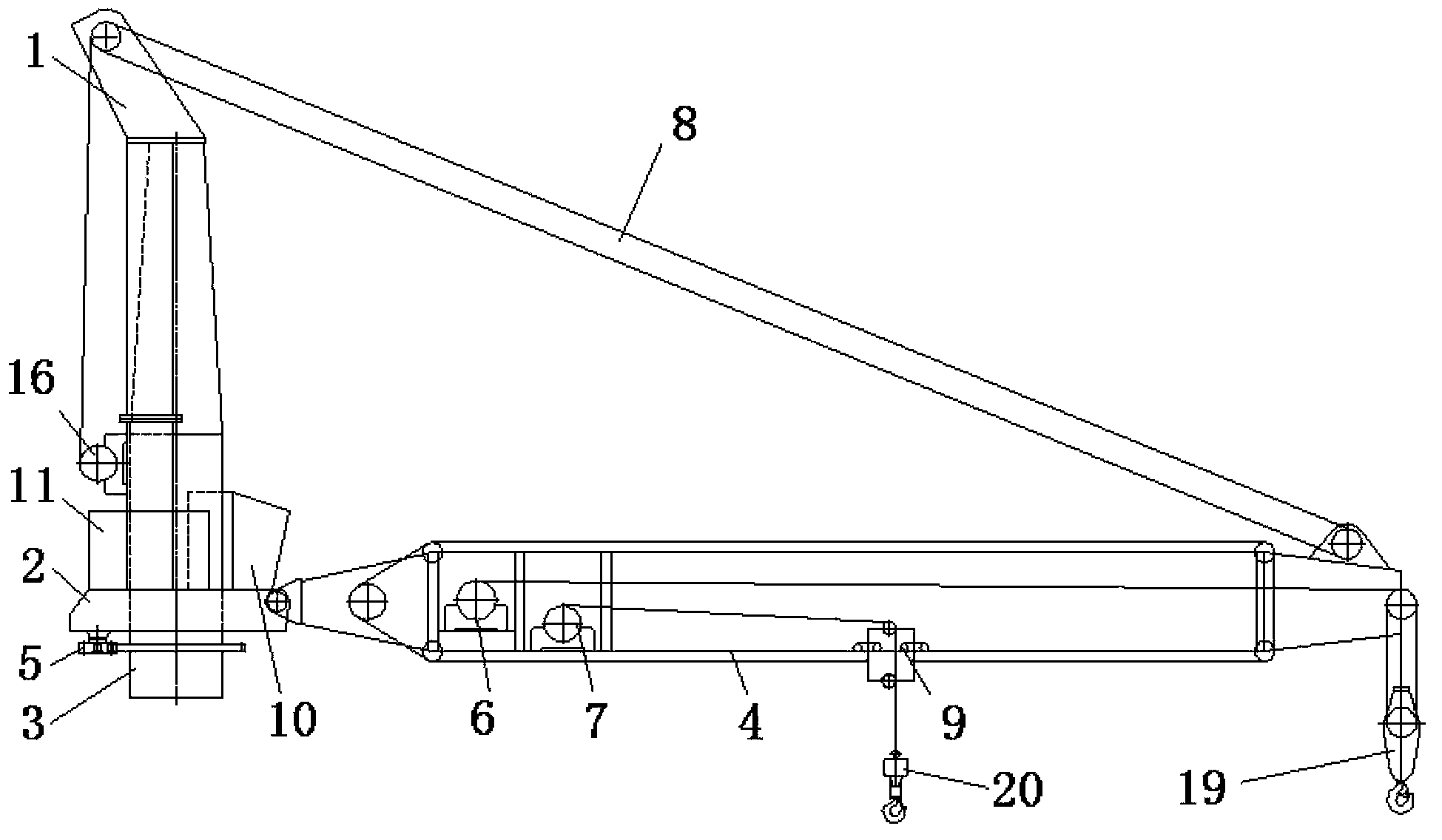

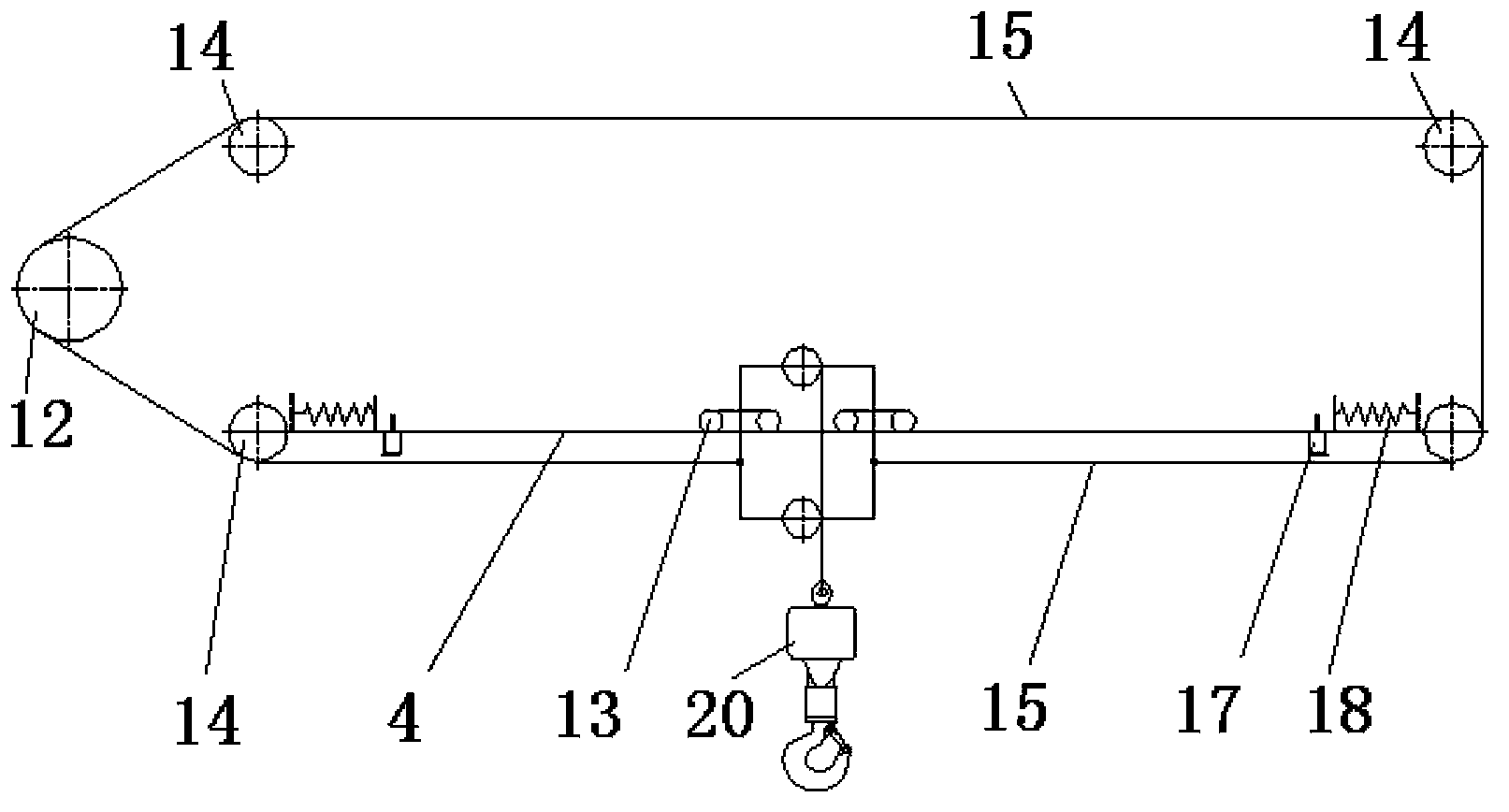

[0012] Such as figure 1 , figure 2 As shown, the structure of the offshore platform crane of the present invention is that a turntable 2 is installed on the general column 3, the turntable 2 is connected to the rotary drive mechanism 5 in transmission, an operation room 10 and a mechanical room 11 are installed on the turntable 2, and a The main luffing winch 16 is installed on the general column 3, the mast 1 is installed on the uppermost end of the general column 3, the turntable 2 is hinged with the boom 4, the end of the boom 4 is provided with a main hook 19, and the end of the boom 4 The head is connected with the mast 1 through the boom luffing mechanism 8. The main lifting mechanism 6, the auxiliary lifting mechanism 7 and the trolley luffing mechanism 9 are arranged in the boom 4. The main lifting mechanism 6 is connected with the main hook 19 through transmission, and the auxiliary lifting mechanism The mechanism 7 is connected with the transmission of the auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com