Self-heating laminated micro-channel reforming hydrogen production reactor

A self-heating cascading, reforming reaction technology, applied in hydrogen, chemical instruments and methods, inorganic chemistry, etc., can solve environmental pollution and other problems, achieve high heat transfer efficiency, improve efficiency, and reduce the risk of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

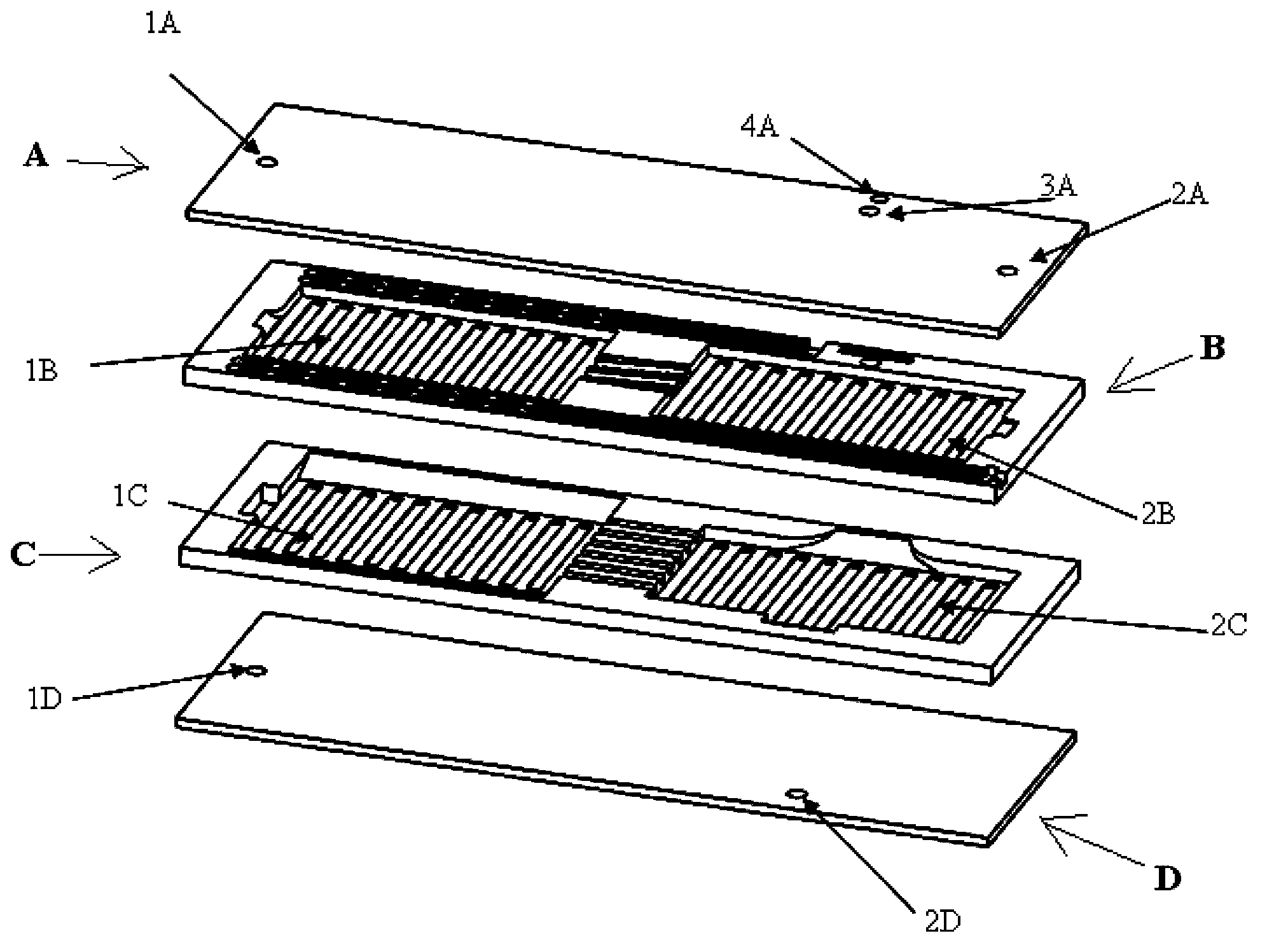

[0035] Such as Figure 1~7 As shown, the self-heating type stacked microchannel reforming hydrogen production reactor of the present invention includes an upper cover plate A, an endothermic reaction substrate B, an exothermic reaction substrate C and a lower cover plate D sequentially stacked from top to bottom;

[0036] Edges between the upper cover plate A, the endothermic reaction substrate B, the exothermic reaction substrate C and the lower cover plate D are sealed and fixed by sealing sheets (not shown in the figure) and bolts (not shown in the figure).

[0037] The upper cover plate A is provided with an inlet 1A for steam reforming reactants, an outlet 2A for steam reforming products, an inlet 3A for hydrocarbons in partial oxidation reforming reactions, and an inlet 4A for oxygen in partial oxidation reforming reactions;

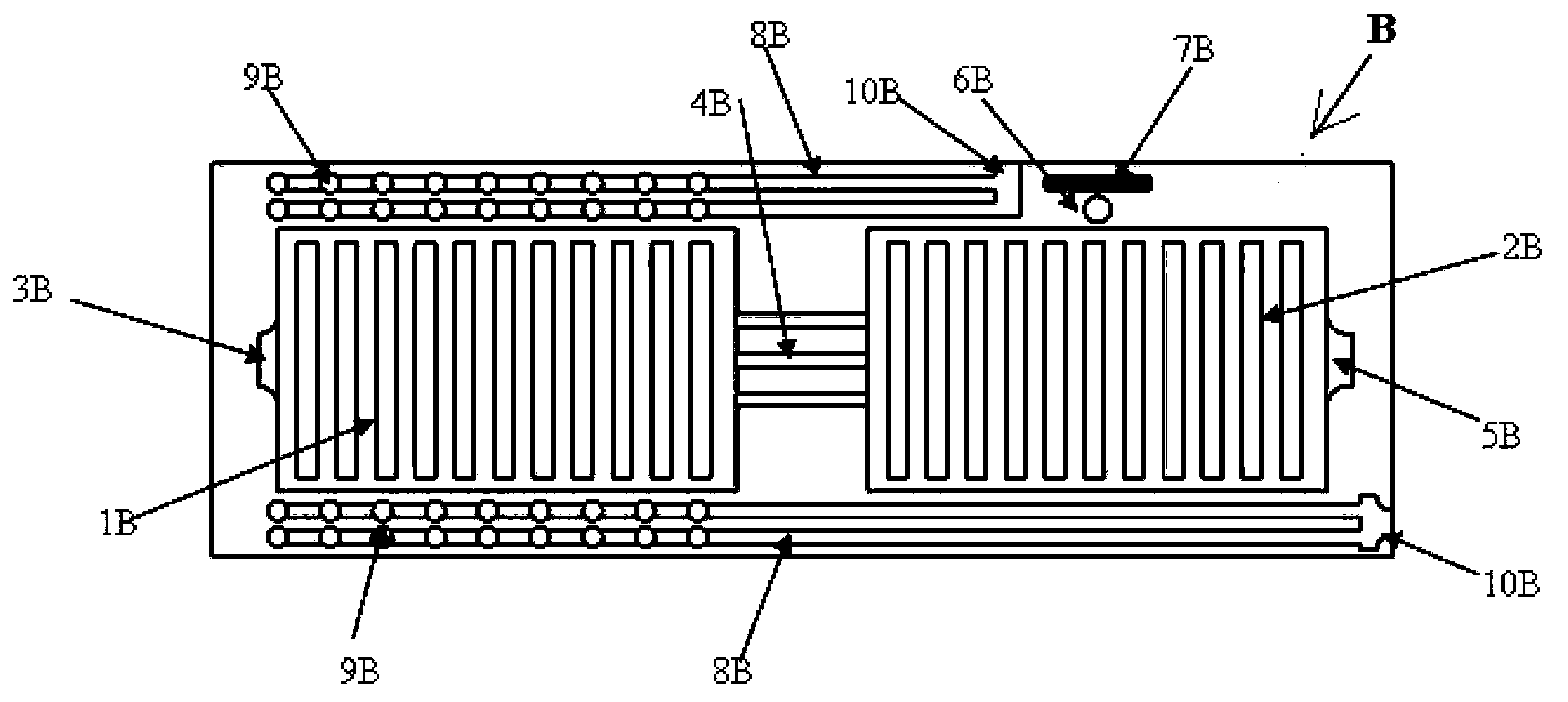

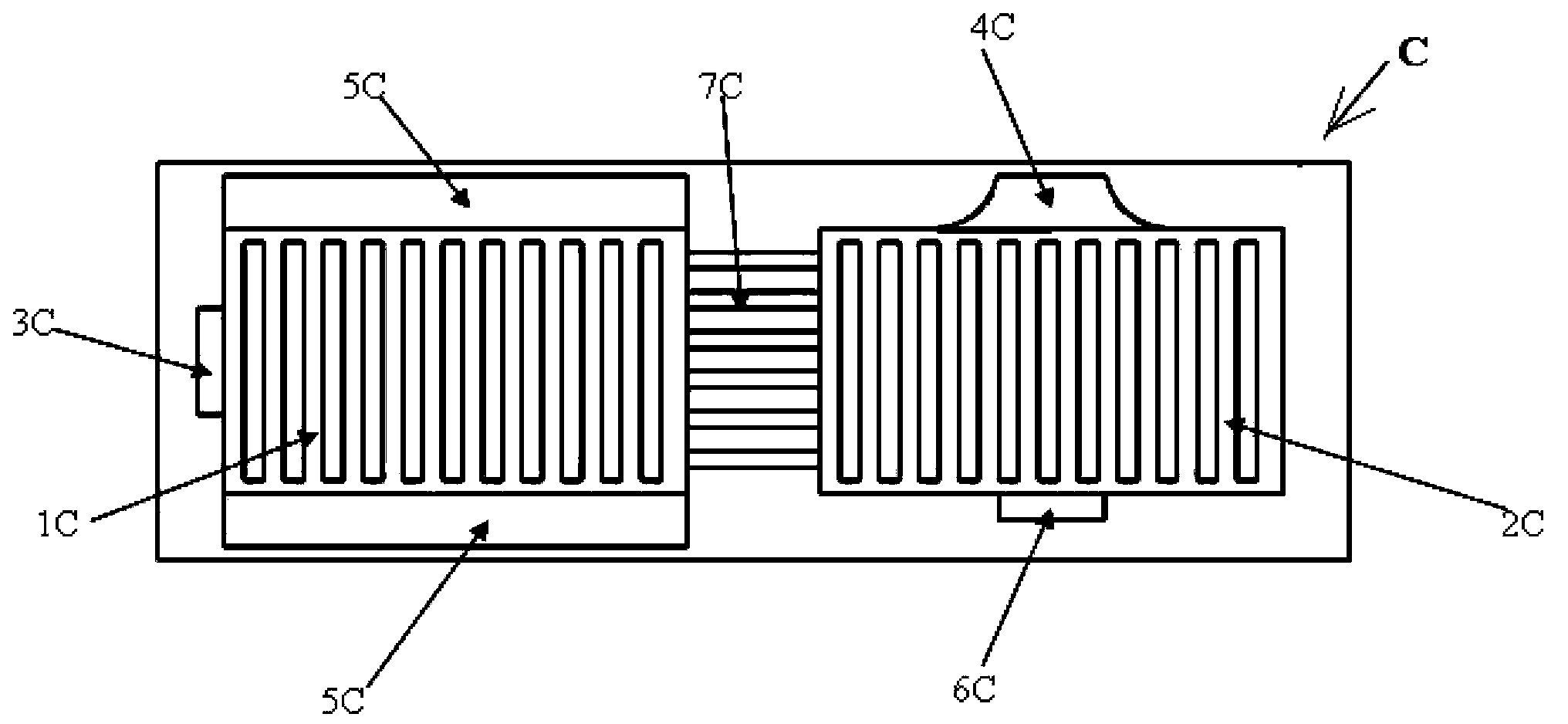

[0038] Such as figure 2 shown. The endothermic reaction substrate B includes a vaporization chamber 1B, a water vapor reforming reaction chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com