Steel wire rope and producing method thereof

A technology of steel wire rope and steel wire, which is applied to textiles, papermaking, textile cables, etc., can solve the problems of high requirements on the anti-rotation performance of steel wire ropes, insufficient solution of the compression ratio of compacted strands and internal stress of the rope, and high lift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

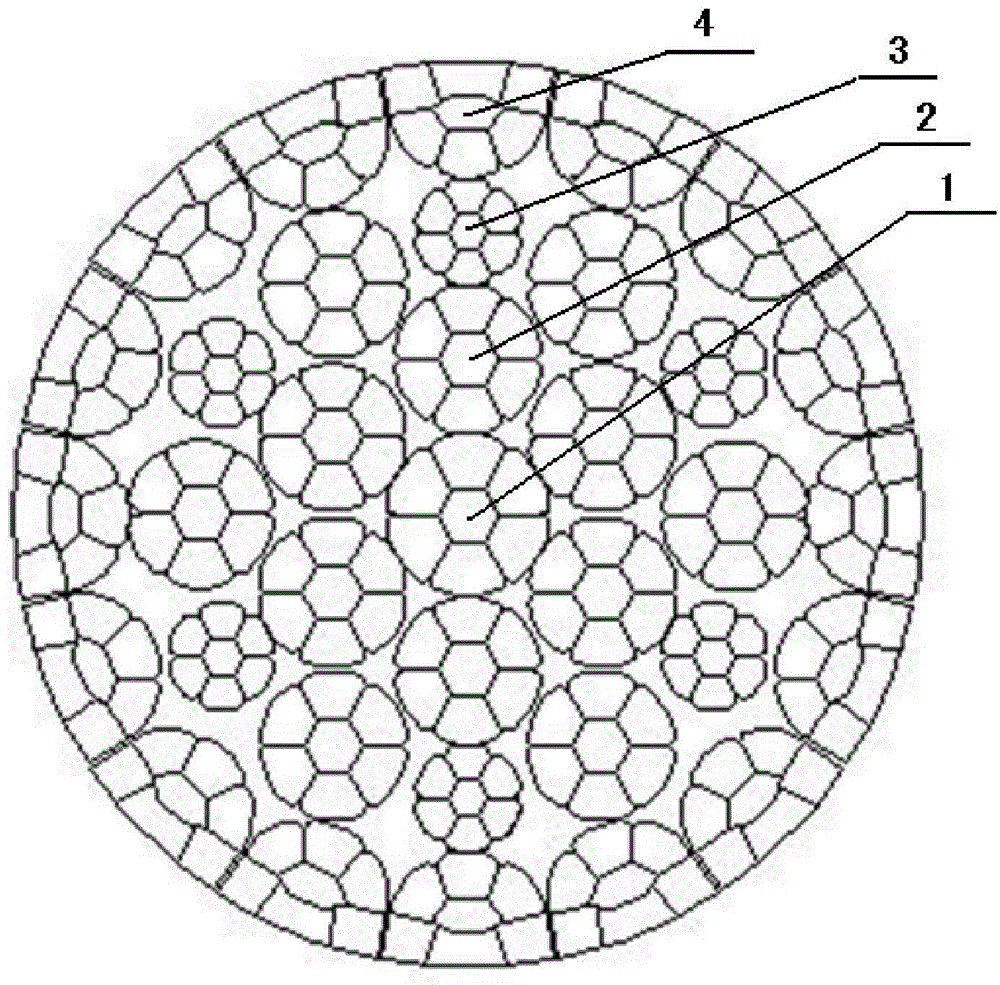

[0018] Such as figure 1 As shown, a steel wire rope is formed by twisting a central strand wrapped by 3 layers of strands. The 3 layers of strands are the inner strand 2, the second inner strand 3 and the outer strand 4. The inner steel wire of the steel wire rope strand and the There is surface contact between steel wires and between strands. The inner layer strand 2 and the second outer layer strand 3 are twisted. The twist direction of the center strand 1 is left lay, and the lay length is

[0019] The diameter of the center rope is 5.9-6.2 times, and the twist direction of the center rope is right-handed with 4 twists in the outer layer, and the lay length is 6.8-7.1 times the diameter of the steel wire rope.

[0020] The steel wire rope strands include 1 central strand 1, 6 inner strands 2, 12 subouter strands 3 and 16 outer strands 4; the 12 subouter s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com