Laterally-driven electric lifting window for transportation mean

A technology for transportation tools and electric windows, applied in transportation and packaging, door/window accessories, engine components, etc., can solve problems such as obstruction, failure of flexible shaft extension and lifting, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

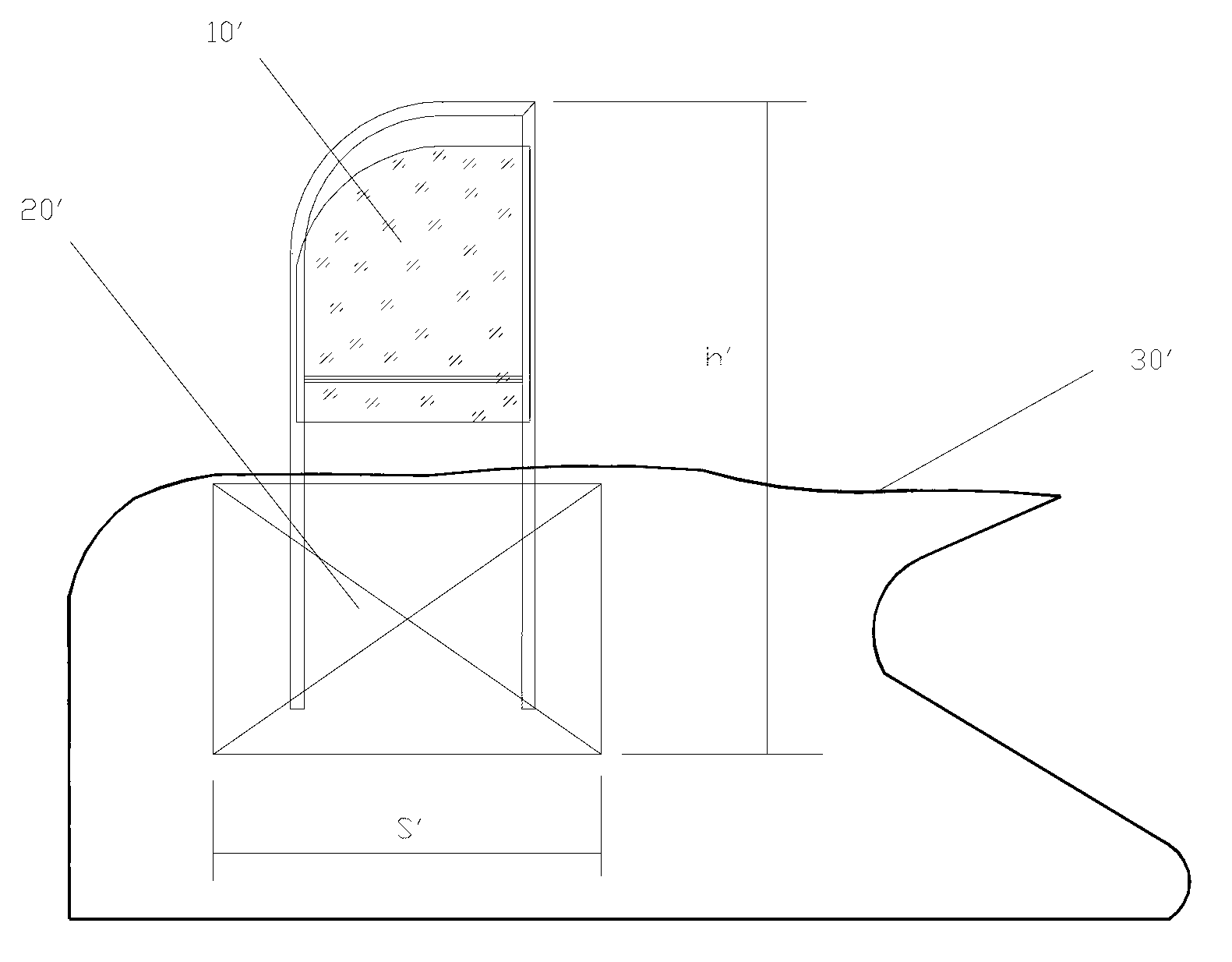

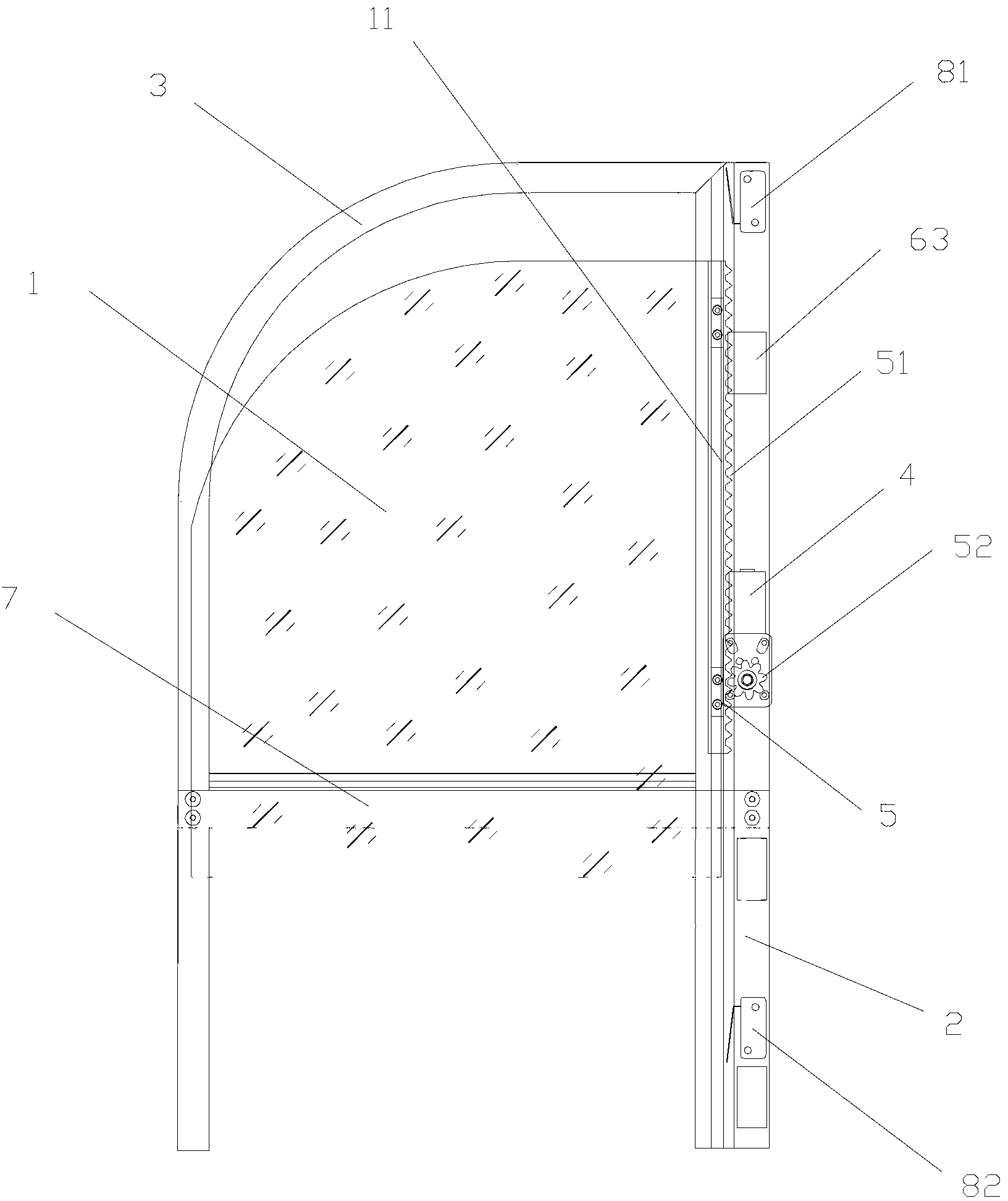

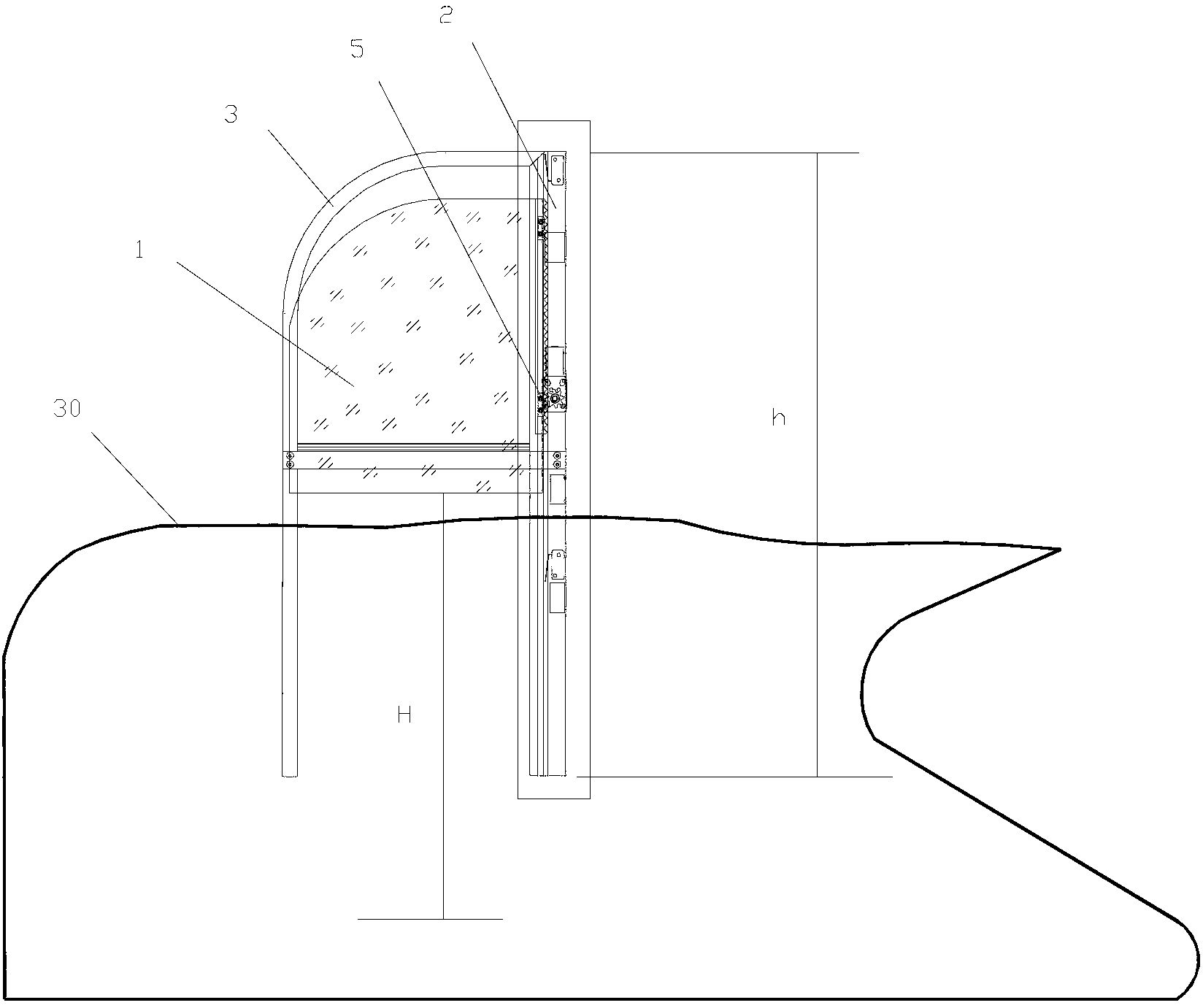

[0046] Embodiment one, see Figure 2 to Figure 14 As shown, a side position driving up and down electric window of a transportation tool of the present invention includes:

[0047] A window glass 1 having edges of a preset shape, one of which is set as a lifting side edge 11 parallel to the up and down direction;

[0048] A column 2 is set to be parallel to the up and down direction of the window glass, and is fixed to the car frame beam 10;

[0049] A glass guide rail 3, wherein the lower part is arranged parallel to the column, the upper part is bent or folded towards the column 2, and the end of the upper part is fixed to the top of the column 2; the glass guide rail 3 and the column 2 form a guide rail for lifting and lowering the window glass, the The window glass 1 is installed in the guide track;

[0050] A driving mechanism 5, the driving mechanism 5 is installed on the lifting side 11 of the column 2 and the window glass of the car / ship, so that when the driving mec...

Embodiment 2

[0071] Embodiment two, see Figure 15 As shown, the side position driving up and down electric window of a transportation vehicle according to the present invention is different from the first embodiment in that the driving mechanism includes a reduction motor 911, a steel wire 912, a roller 913 and a fixing piece 914; The roller 913 and the deceleration motor 911 are installed on the upper and lower sides of the column 2 respectively; one end of the steel wire 912 is linked with the deceleration motor 911, and the other end of the steel wire 912 is fixed with the fixing member 914 after bypassing the roller 913. The fixing part 914 is fixed with the lifting side edge 11 of the car / ship window glass.

Embodiment 3

[0072] Embodiment three, see Figure 16 As shown, the side position driving up and down electric window of a transportation vehicle according to the present invention is different from the first embodiment in that the driving mechanism includes a reduction motor 921, a chain 922, a sprocket 923 and a fixing member 924; The sprocket 923 and the reduction motor 921 are installed on the upper and lower sides of the column 2 respectively; one end of the chain 922 is linked with the reduction motor 921, and the other end of the chain 922 is fixed with the fixing member 924 after bypassing the sprocket 923 , the fixing member 924 is fixed to the lifting side edge 11 of the car / ship window glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com