Sealing method for lateral side of sintering machine

A sintering machine and end sealing technology, which is applied to the sealing of the engine, mechanical equipment, engine components, etc., can solve the problems of not being able to prevent air leakage, and achieve the effects of preventing air leakage, avoiding resistance loss, and reducing air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

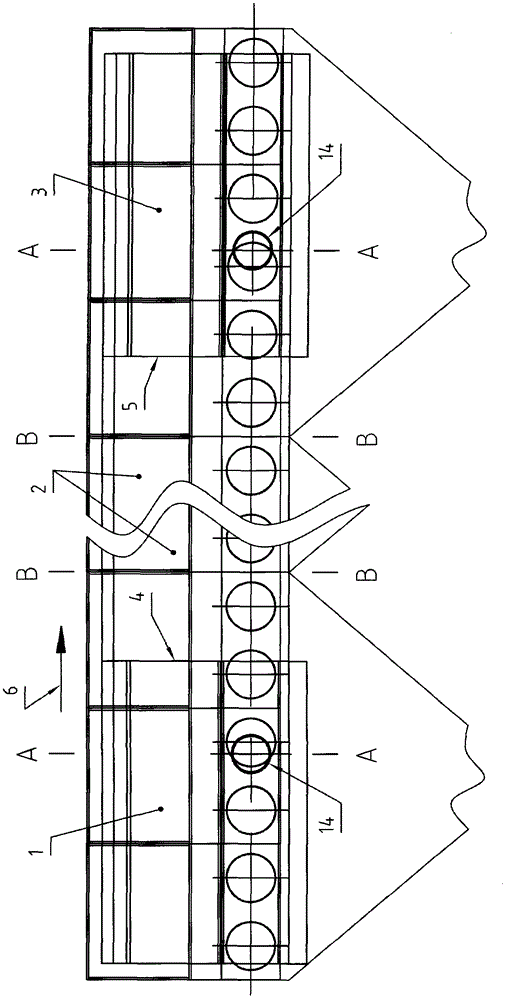

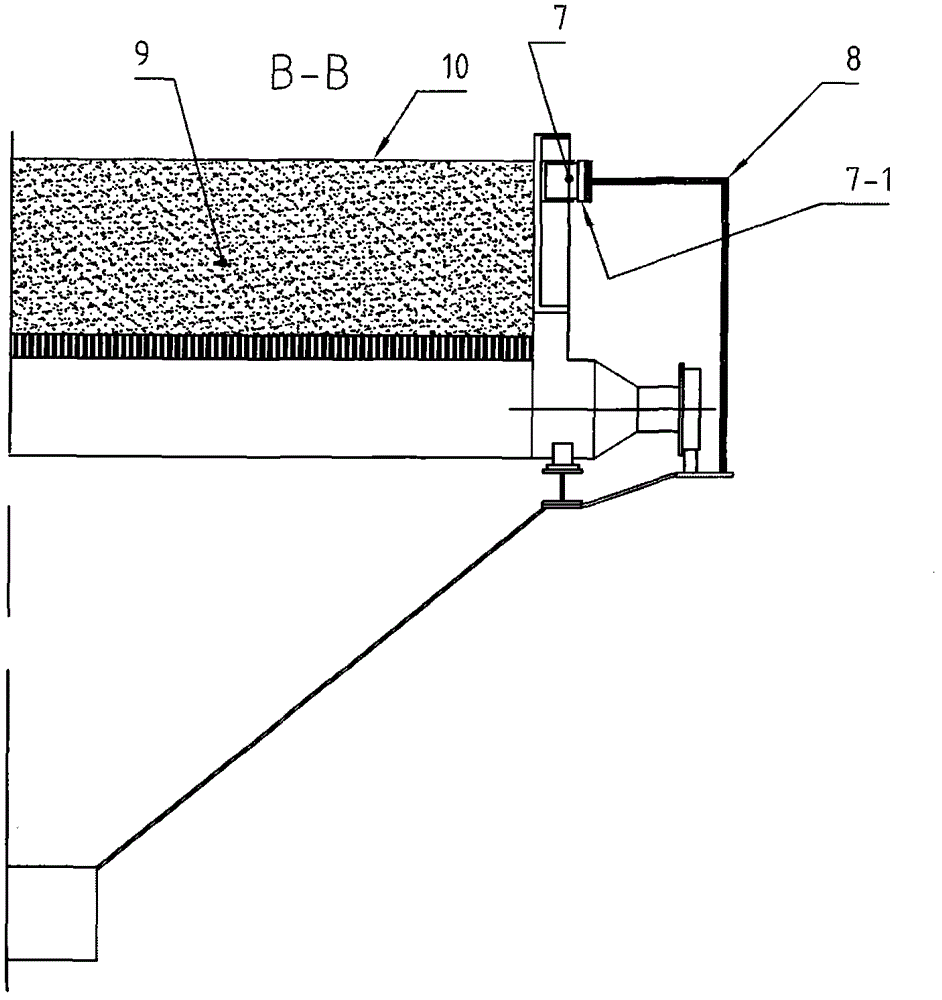

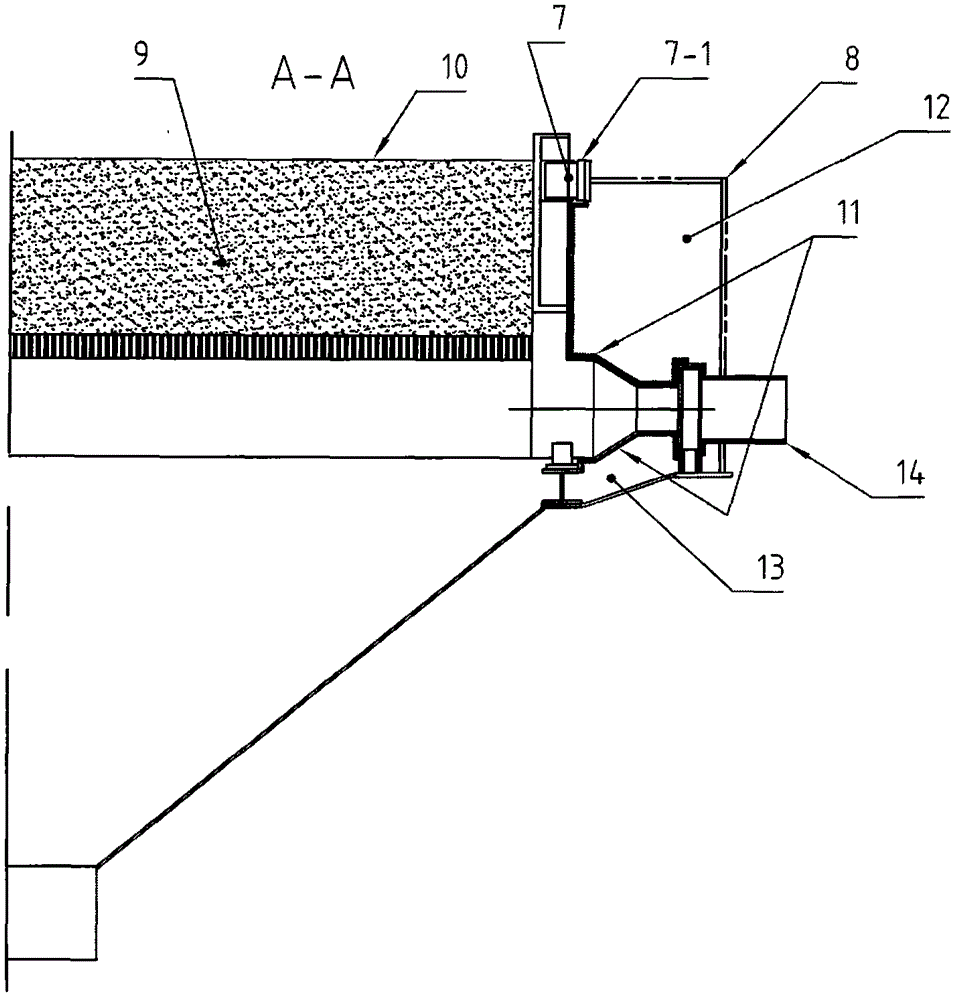

[0019] Example 1, such as figure 1 , figure 2 and image 3 shown.

[0020] figure 1 It is a side view of Embodiment 1 of the present invention to express the overall overview of this embodiment.

[0021] from figure 1 It can be seen from the figure that this embodiment is divided into 3 large sections: 1 is the front end sealing section. 2 is the middle segment. 3 is the end sealing section at the rear. 4 and 5 are the interface between the front end sealing section 1 and the rear end sealing section 3 and the middle section 2 respectively. And the arrow 6 represents the running direction of the sintering machine trolley. And 14 is the air introduction port that is provided with at the described trough type end sealing mechanism place. Induction of air through the air inlet 14 can prevent the air leakage of the sintering machine from entering the main exhaust fan, avoid the subsequent resistance loss caused by the air leakage air volume, and reduce the power of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com