Online monitoring device for mechanic-electrical integrated SF6 density moisture

A monitoring device and an integrated technology, which is applied in the field of electromechanical integrated SF6 gas density and micro-water online monitoring device, can solve the problems of increased air leakage probability, inaccurate detected data, and difficult operation, so as to improve accuracy and operate The effect of convenience, increased flexibility and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

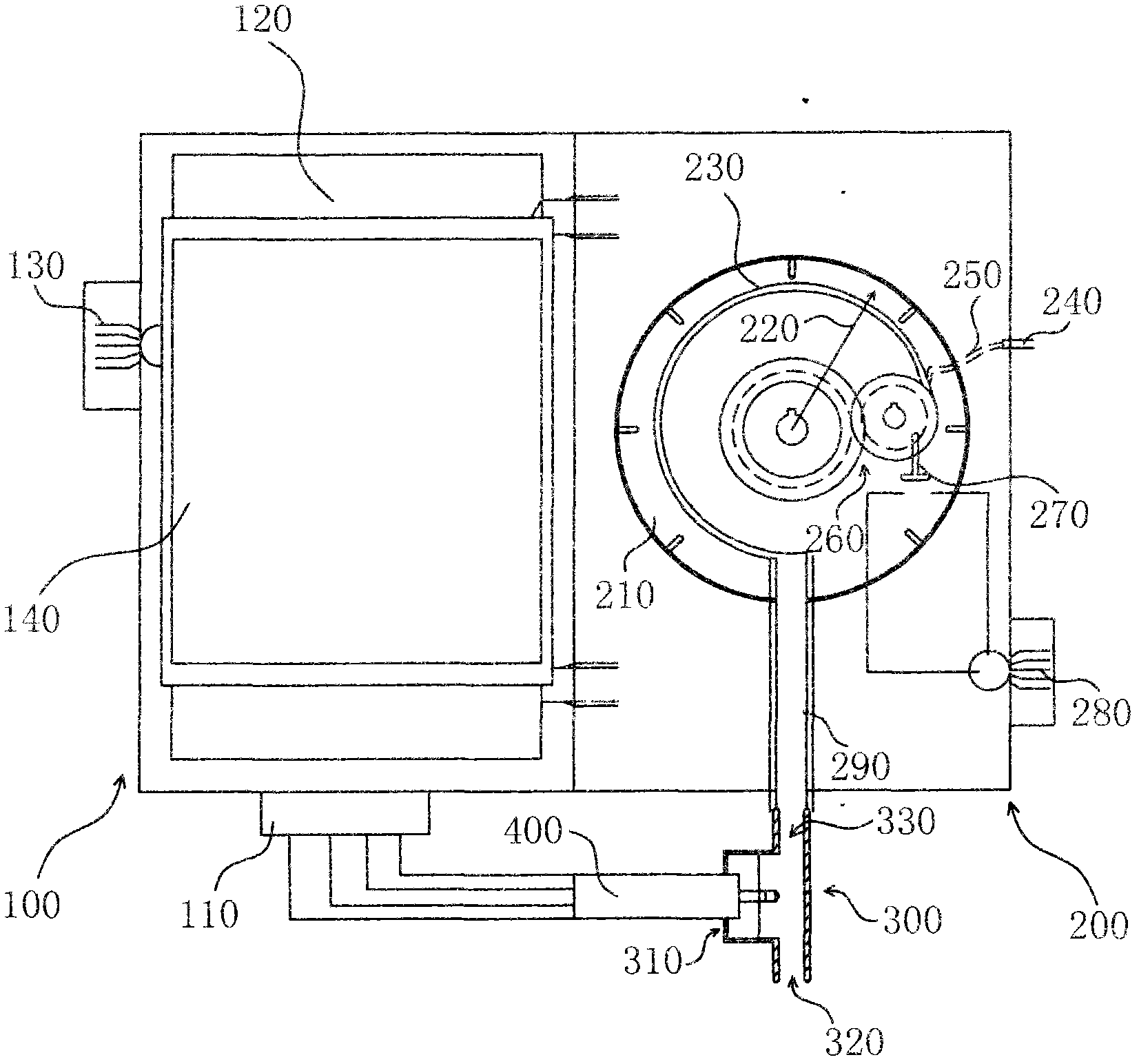

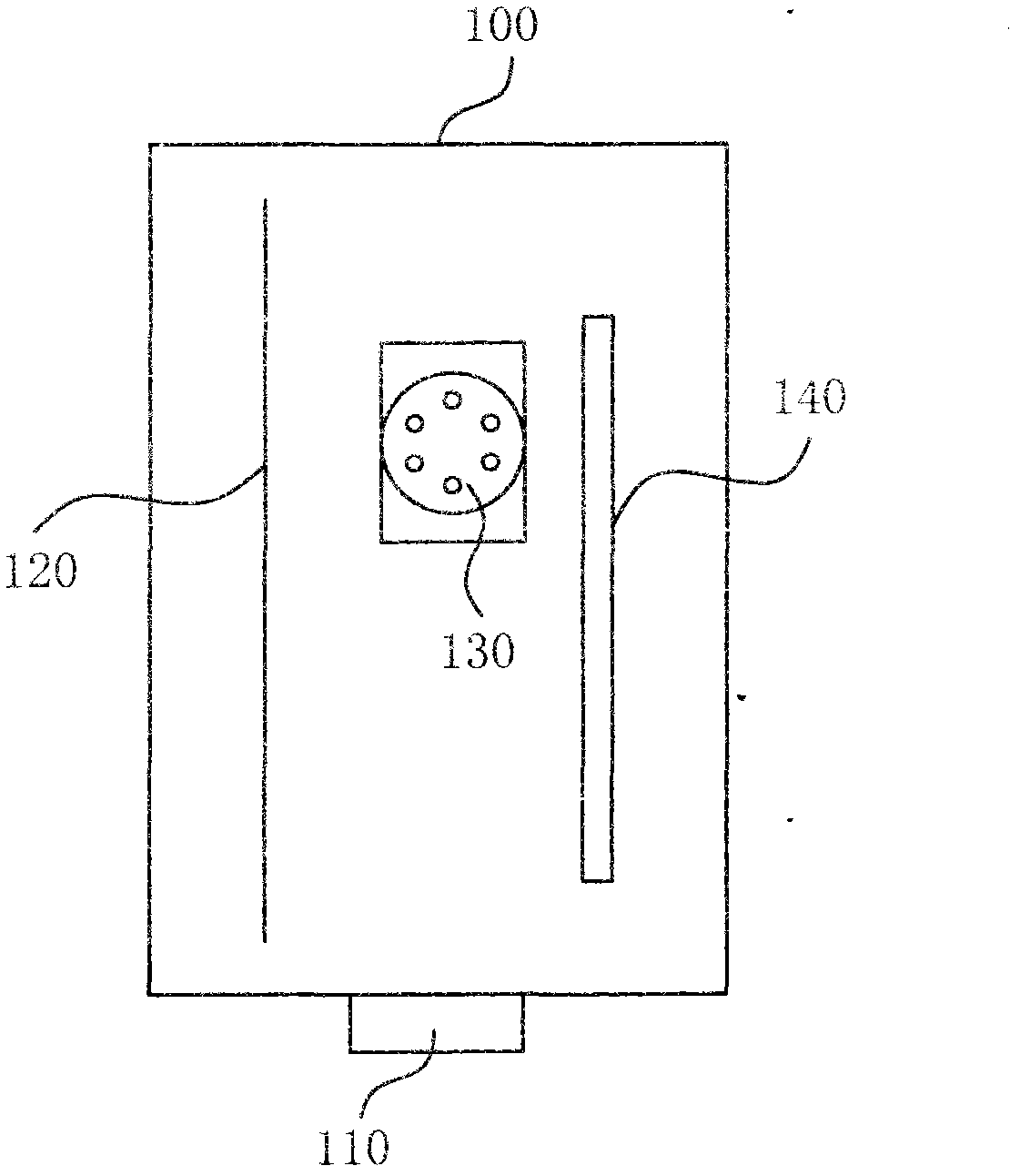

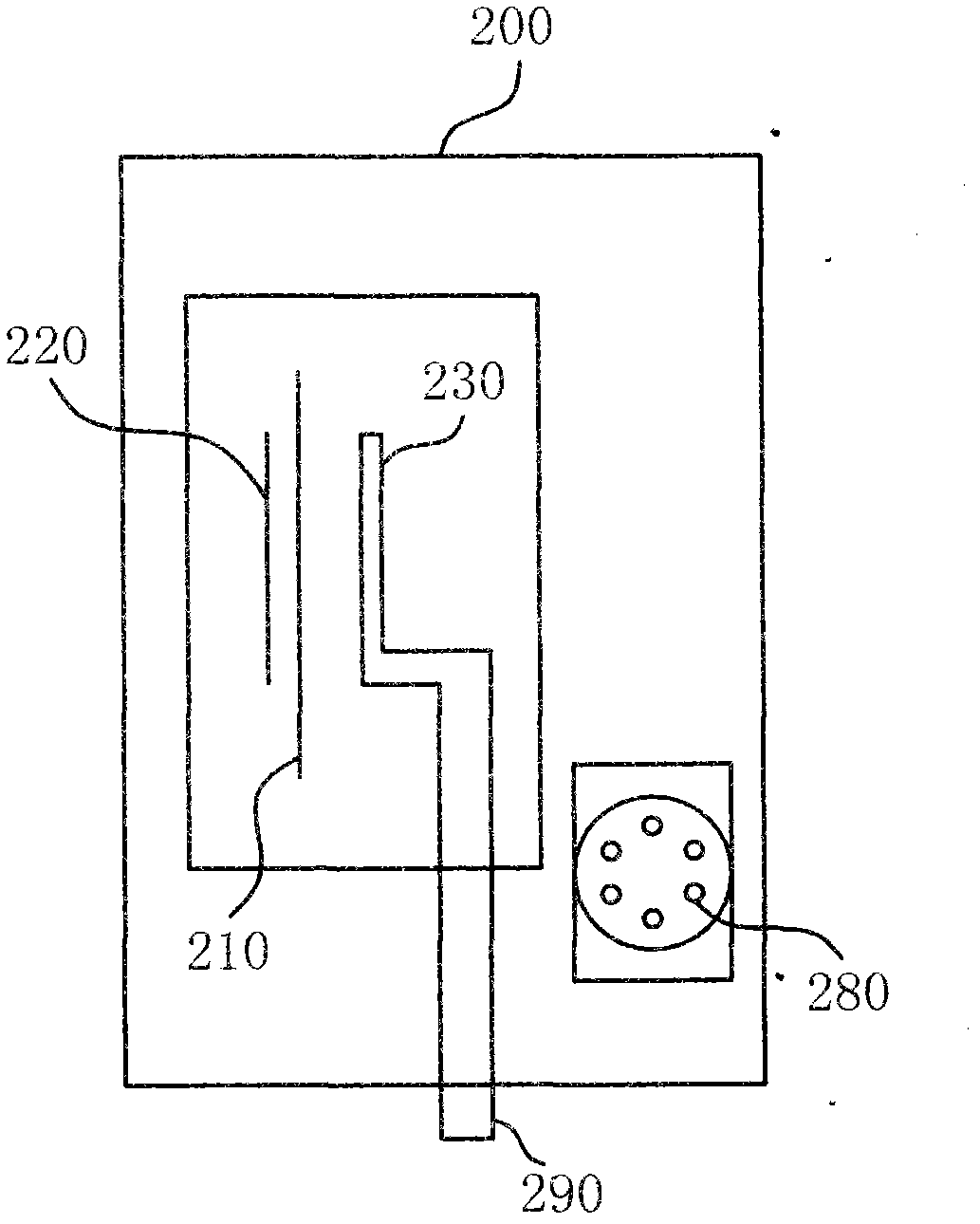

[0024] like figure 1 , 2 , 3, the electromechanical integrated SF6 density micro-water online monitoring device includes an electronic density micro-water module 100, a mechanical density module 200, a joint mechanism 300 and a detection module 400, and the detection module 400 includes a detection part and a transmission part. The part extends into the gas to detect the SF6 density and micro-water value in the gas, and the transmission part is used to transmit the detection result of the detection part to the electronic density micro-water module 100 in the form of electrical signals. Preferably, the detection part of the detection module 400 includes an electronic pressure sensor, an electronic humidity sensor and an electronic temperature se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com