Flexible positioning wear-less vibrating sand filling device for fuse protectors

A flexible positioning and fuse technology, applied in the direction of fuse manufacturing, etc., can solve problems such as the compactness cannot meet the predetermined requirements, the surface of the fuse is easy to wear, uneven sand filling, etc., to reduce manual labor, avoid human factors, Reduce the effect of production processes and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

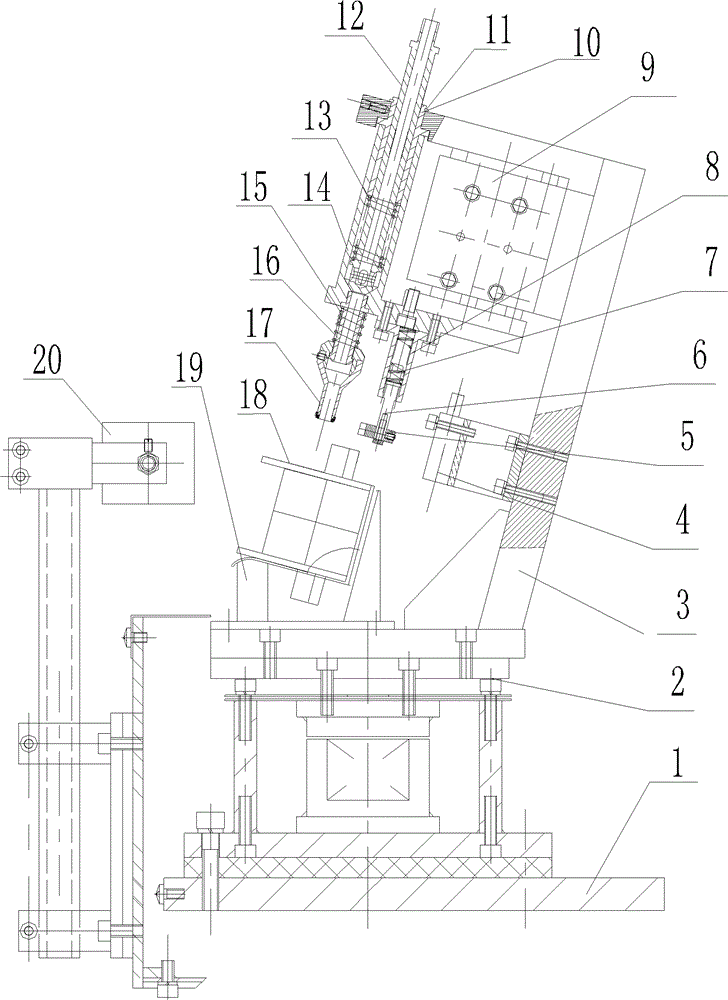

[0023] Such as figure 1 As shown, a flexible positioning wear-free vibrating fuse sand filling device includes a multi-station turntable 1, a vertical frequency conversion vibrator 2, a support 3, a vibrator power switch 4, and a flexible compression positioning assembly (by a positioning block 5, a guide Shaft 6, preload spring 7, guide sleeve 8), sand filling cylinder 9, preload tracking type sand filling valve (composed of valve guide sleeve 10, spring retaining ring 11, valve core 12, preload spring 13, valve body 14 , spring 15), flexible sand filling nozzle assembly (composed of sand guide pipe 16, sand filling nozzle 17), fuse 18, fuse support 19, sand filling sensor assembly (composed of photoelectric sensor 20, Hall sensor, electromagnetic pneumatic valve and electromagnets).

[0024] The vertical frequency conversion vibrator 2 is set on the multi-station turntable 1, and the vertical frequency conversion vibrator 2 makes the sand filling device vibrate with variabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com