Field structure of an electrical machine

A technology of field structure and generator, applied in the field of field structure, can solve the problems of increasing the total weight of the rotor, wide air gap, dangerous method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

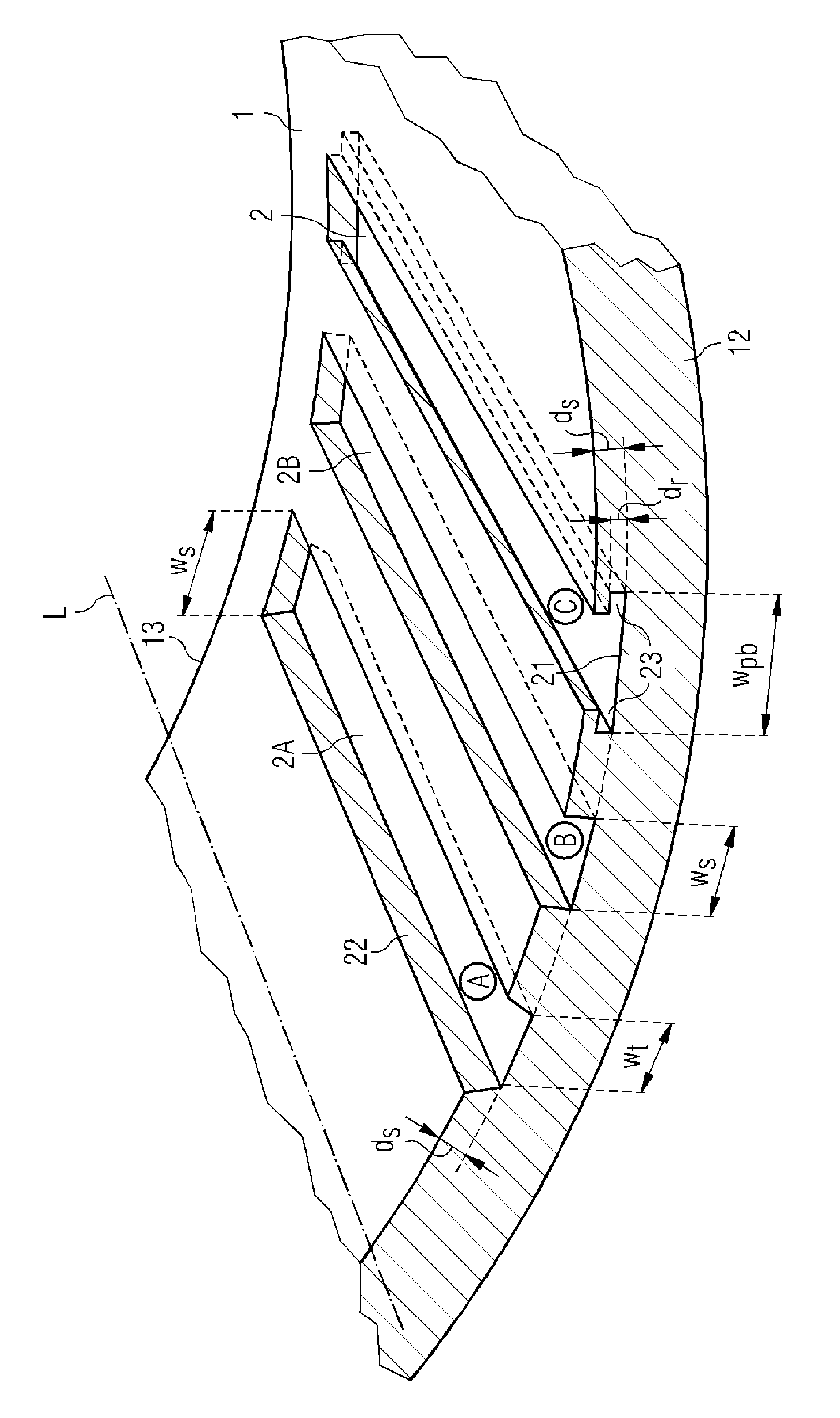

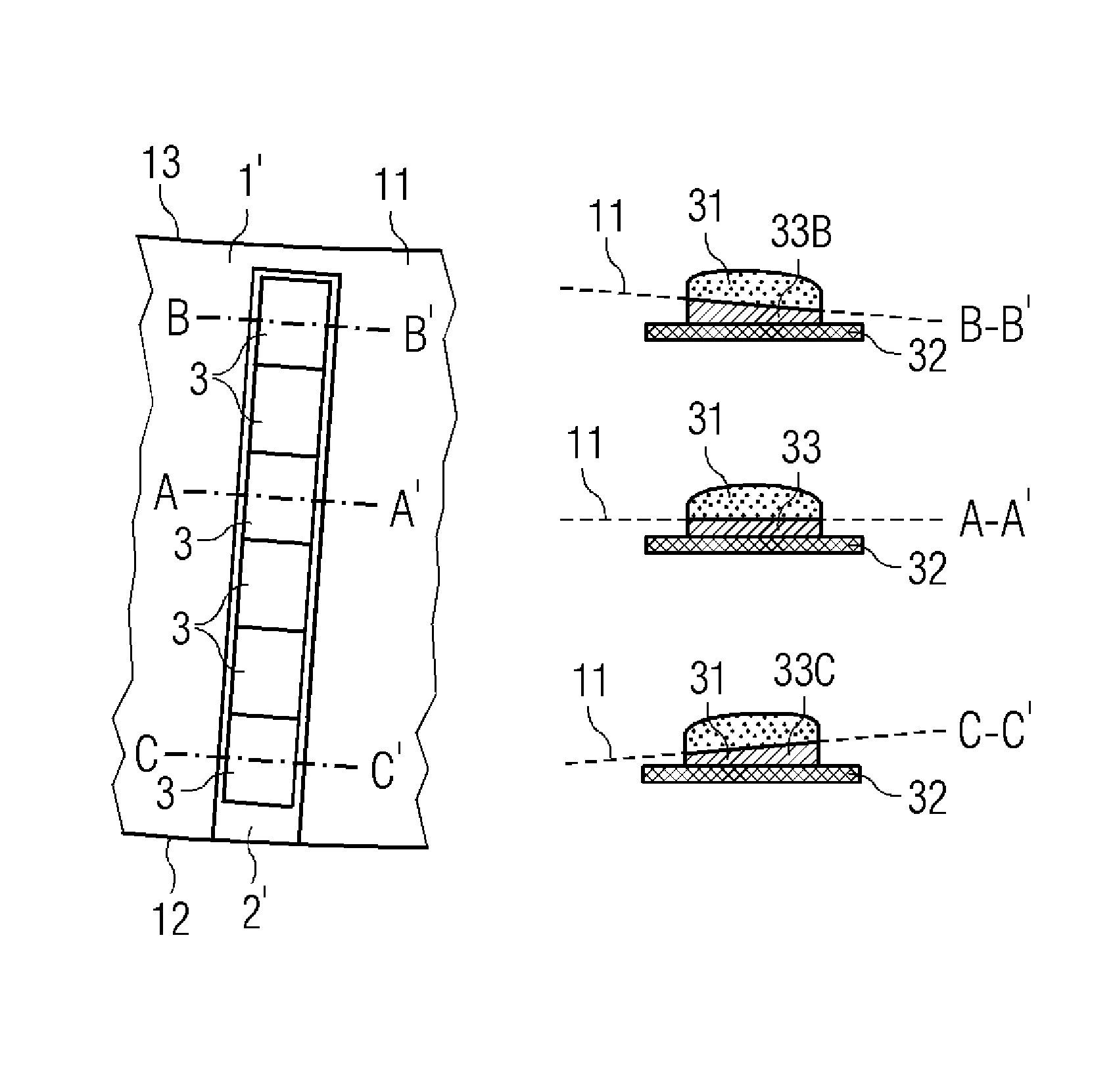

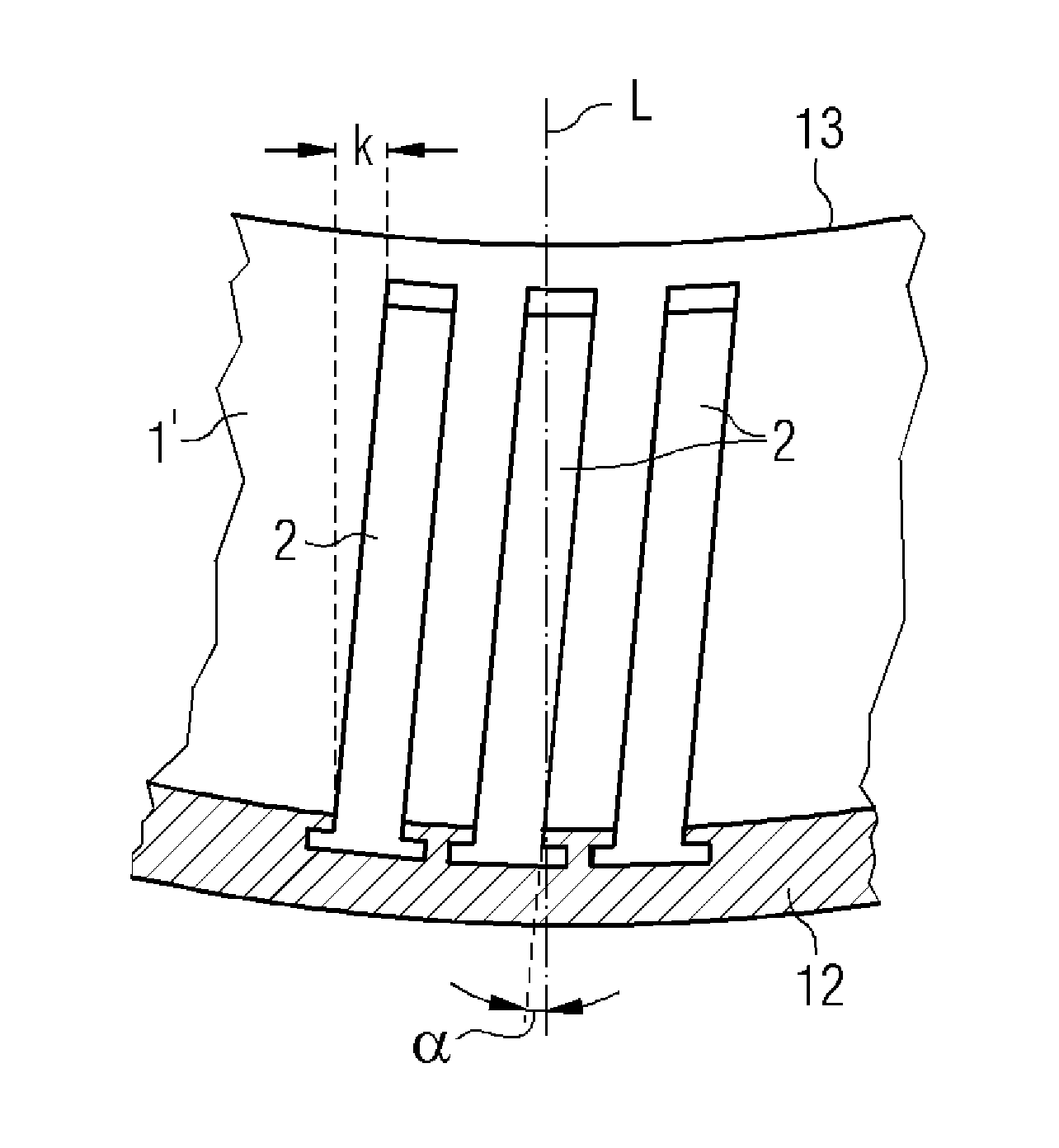

[0037] The same reference numerals refer to the same objects throughout the drawings. Objects in the drawings are not necessarily drawn to scale. In particular, the relative lengths and widths of the rotor slots or magnet assemblies may not correspond to the lengths and widths of actual embodiments of these components, they are depicted as such for clarity only.

[0038] figure 1 A magnet assembly 3 according to a first embodiment of the invention is shown. Here, the magnet assembly 3 includes a base plate 32 on which an intermediate plate 33 is mounted. The pole pieces 31 are mounted on the intermediate plate 33 . Here, four such pole pieces 31 separated by small air gaps are arranged on a carrier 32 , 33 . Of course, this number is only exemplary. The intermediate plate 33 is spot welded to the base plate 32 , with the welds being located between adjacent pole pieces 31 . The magnet arrangement can be sealed in a metal or epoxy cover (not shown here) to protect against...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com