Wind turbine blades with dimples

A wind turbine and blade technology, applied in the field of horizontal axis wind turbine blades, can solve problems such as pressure difference and reduce blade rotation speed, so as to achieve the effect of reducing pressure, reducing negative impact and maximizing income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

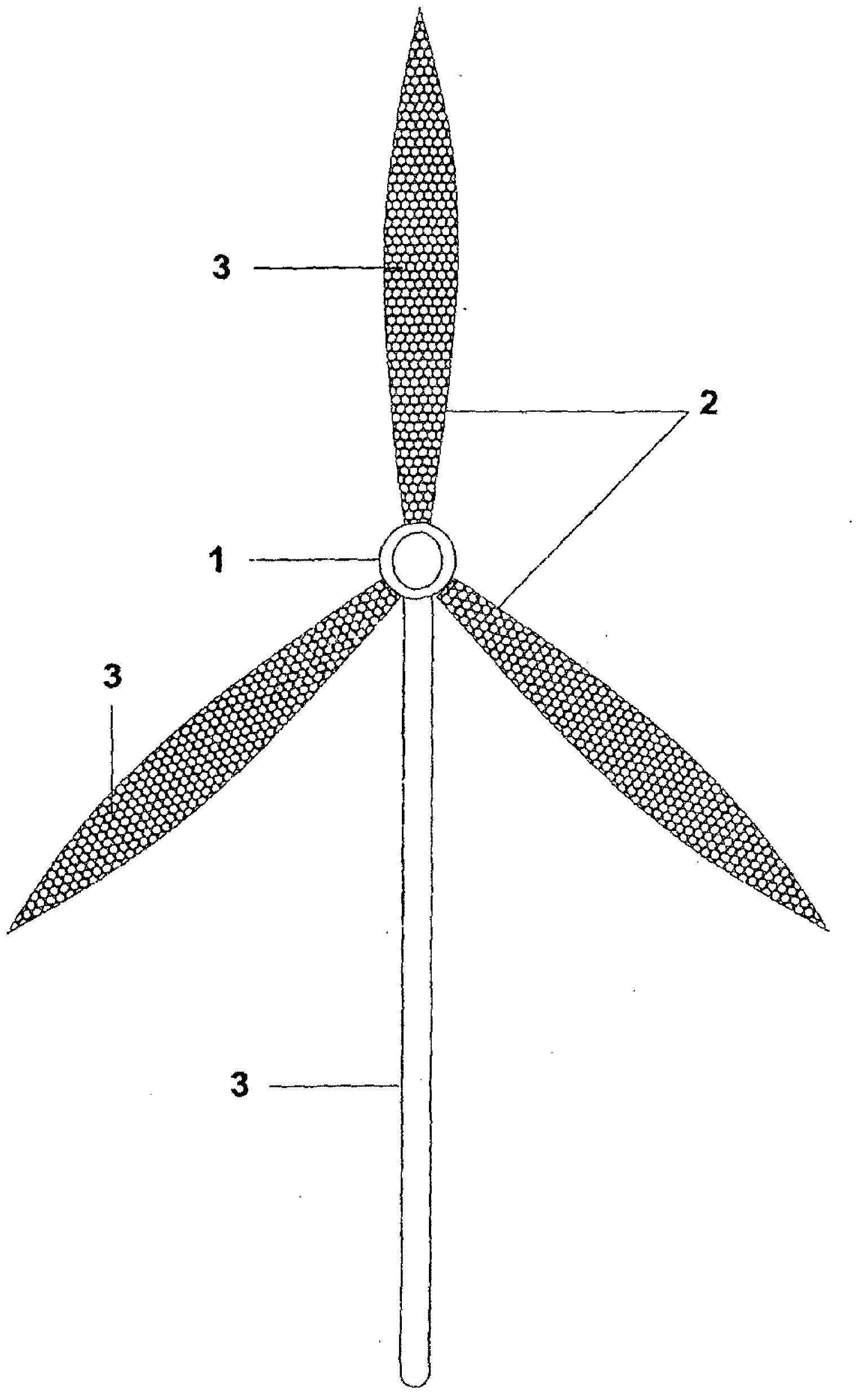

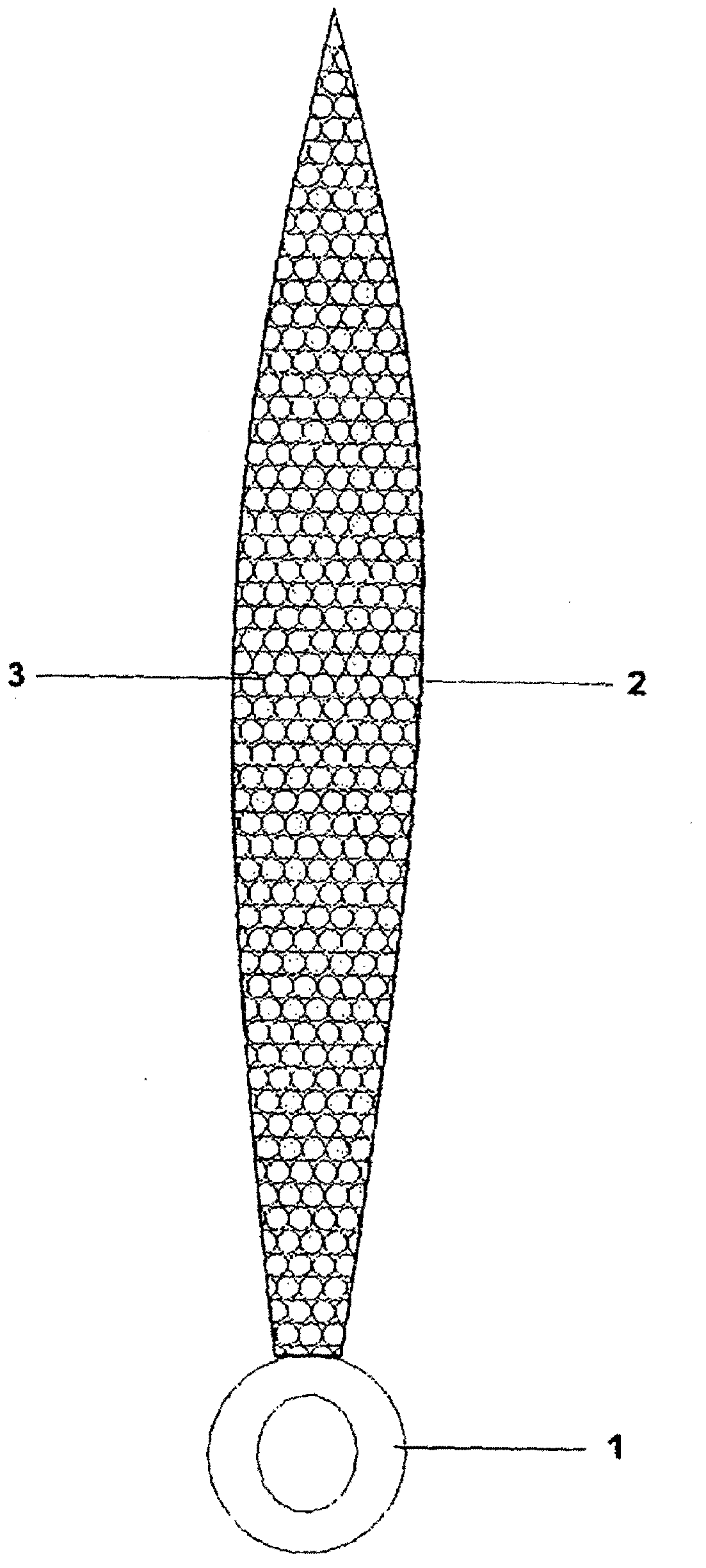

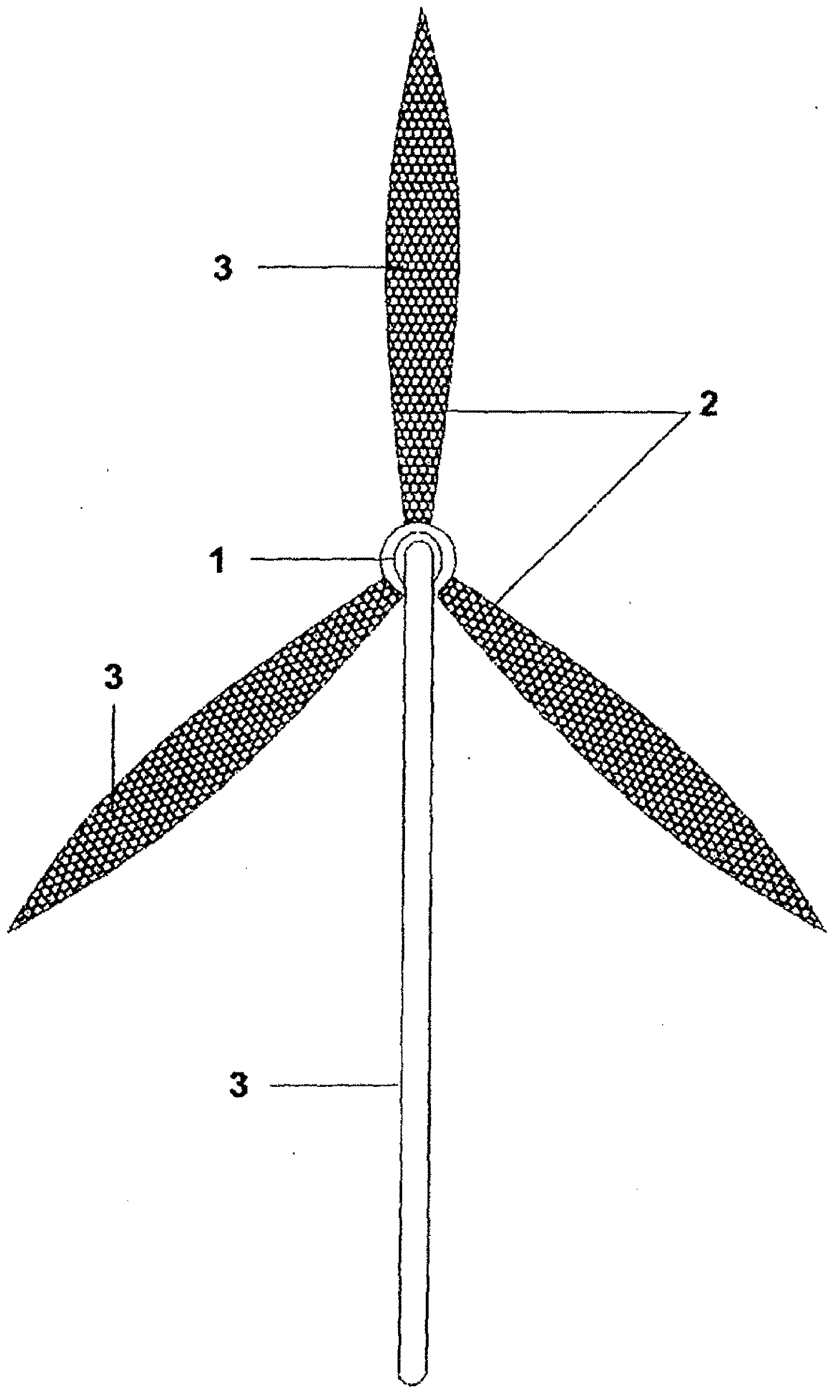

[0013] A method of applying groove arrangement technology on the surface of a wind turbine blade is described with reference to the accompanying drawings. A wind turbine consists of a rotor (1), blades (2), hemispherical grooves (3) and a wind turbine tower (4). The grooves are arranged in rows on the surface of the blade in the highest number and with an ideal effective size according to the surface size of the blade, as close as possible to each other and alternating with each other, resulting in a tangential form.

[0014] As shown in the drawings, only hemispherical grooves of the same size are arranged on the blade surface. However, this does not exclude the implementation of only polygonal grooves (such as hexagonal grooves) arranged on the basis of hemispherical groove arrangement technology, these polygonal grooves are as close as possible to each other, arranged in rows and alternate with each other, resulting in phase Cut in such a way that the surface of the blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com