Bearing arrangement, method for detecting wear of a bearing surface in a bearing arrangement and use of a bearing arrangement

A bearing device and bearing surface technology, which is used in the detection of bearing surface wear in the bearing device, the device for detection of bearing surface wear, and the application field in turbochargers, can solve problems such as limited application of optical fiber filaments, and avoid The effect of high repair cost, simple structure and cheap structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

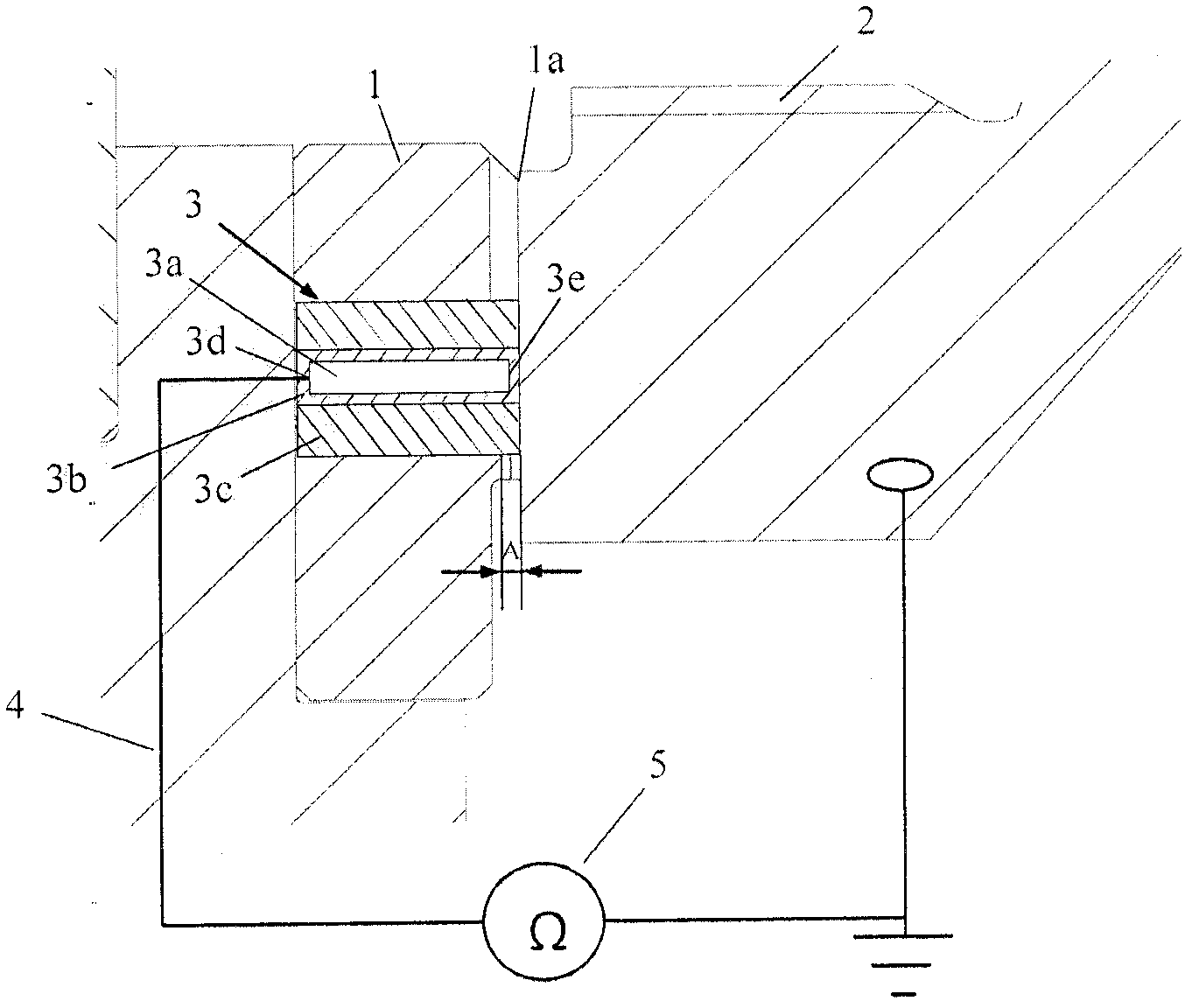

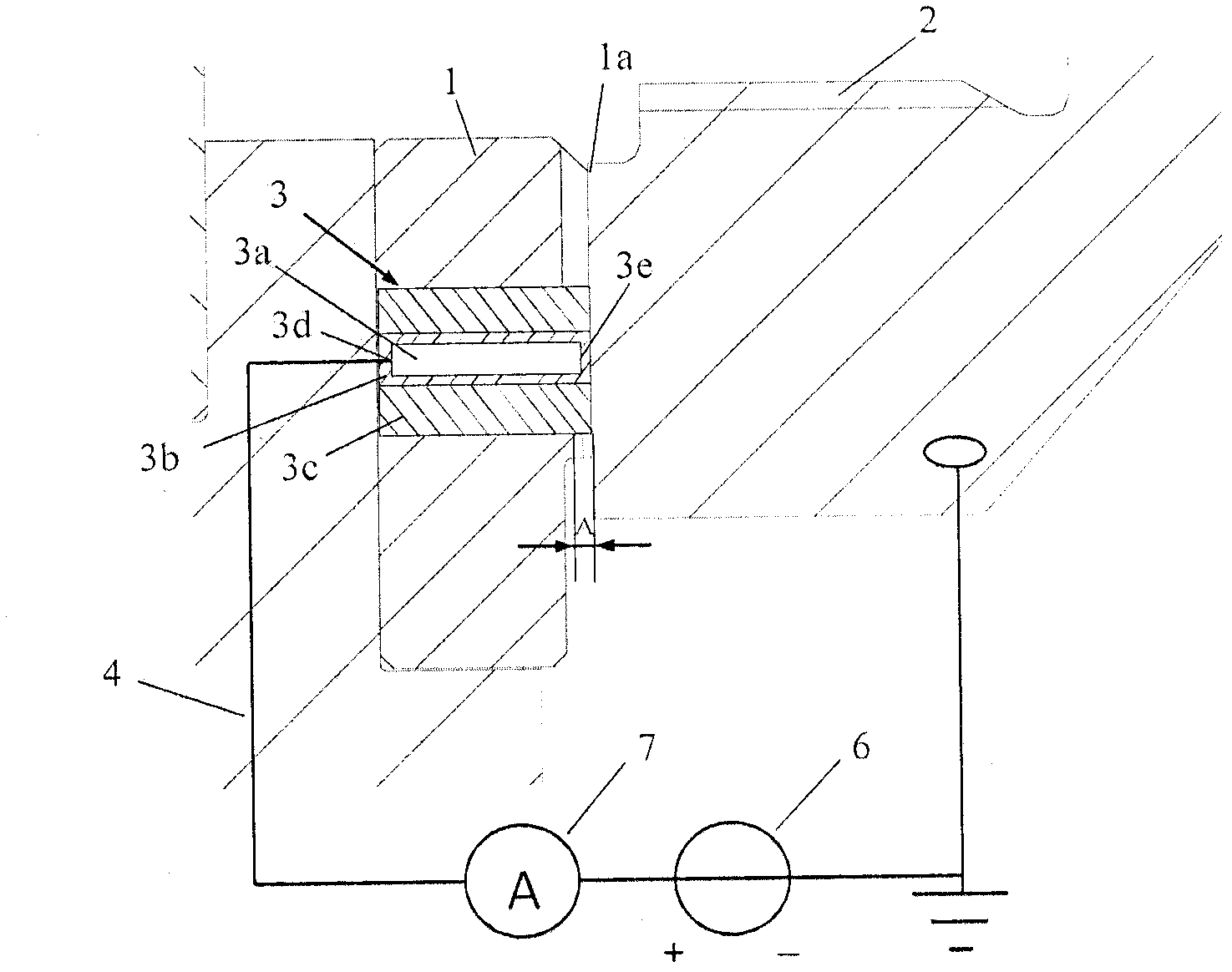

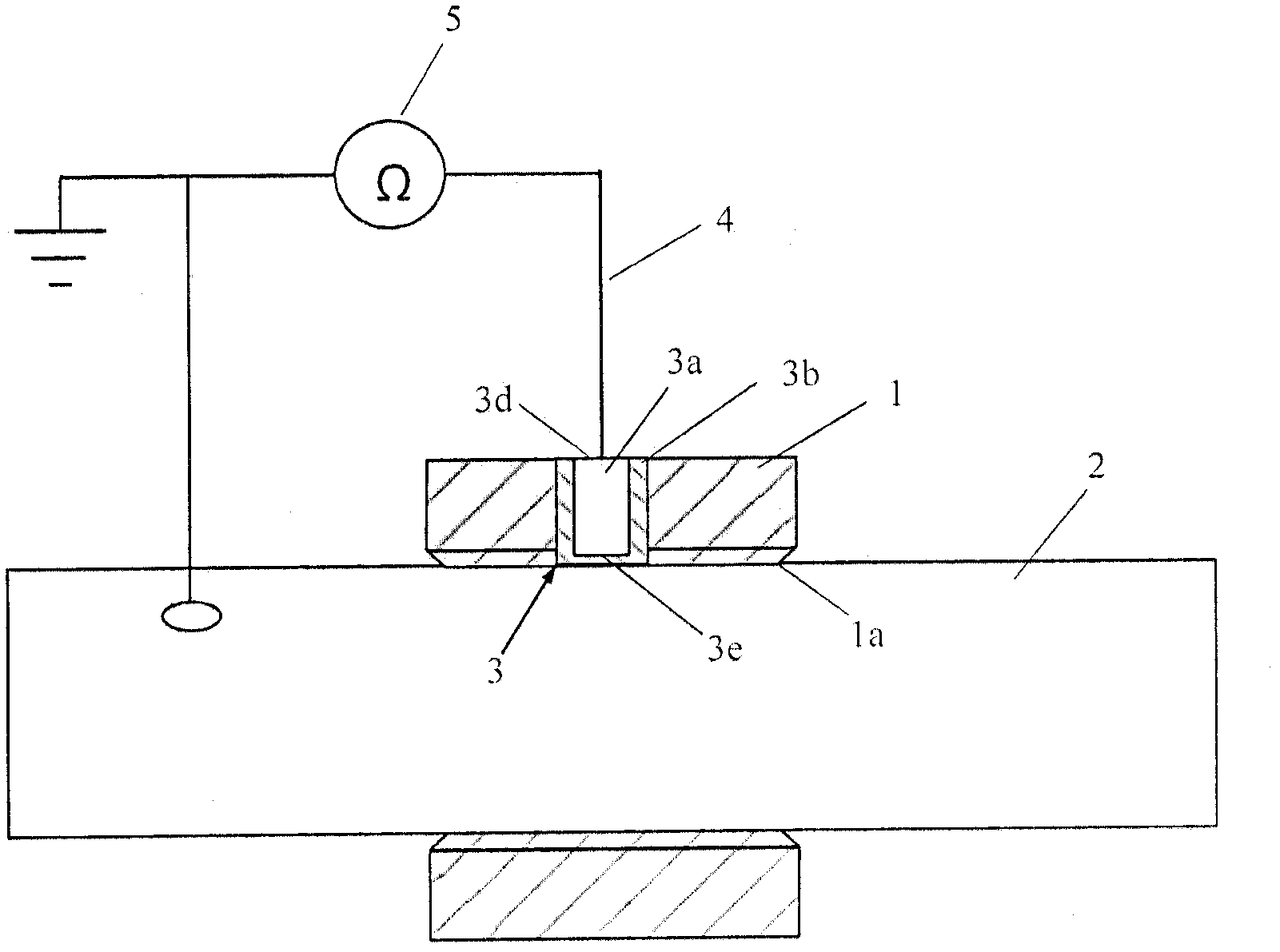

[0018] Some embodiments of the invention will now be described with reference to the accompanying drawings. figure 1 An embodiment of the invention is shown in relation to a thrust bearing. figure 1 The bearing arrangement is designed to allow rotational movement between two parts as well as to carry axial loads. The bearing arrangement can be used, for example, to support the main shaft of a turbocharger of an internal combustion engine, although a bearing arrangement of this type can also be used in many other applications.

[0019] The bearing arrangement comprises a stationary first part 1 , and a second part 2 which is a thrust disc in sliding contact with the first part 1 . The first part 1 has a bearing surface 1 a against which the thrust disc 2 rotates. In many applications it is desirable to arrange lubrication between the first part 1 and the second part 2, but not all cases are necessary. The materials of the first part 1, the bearing surface 1a and the thrust d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com