Method reducing (N'-Nitrosonornicotine) NNN content in tobaccos

A tobacco leaf and content technology, applied in the directions of tobacco, tobacco processing, application, etc., can solve the problems of reducing NNN, cigarette aroma and smoke loss by tobacco leaf treatment, and achieve the effect of obvious effect, strong controllability and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

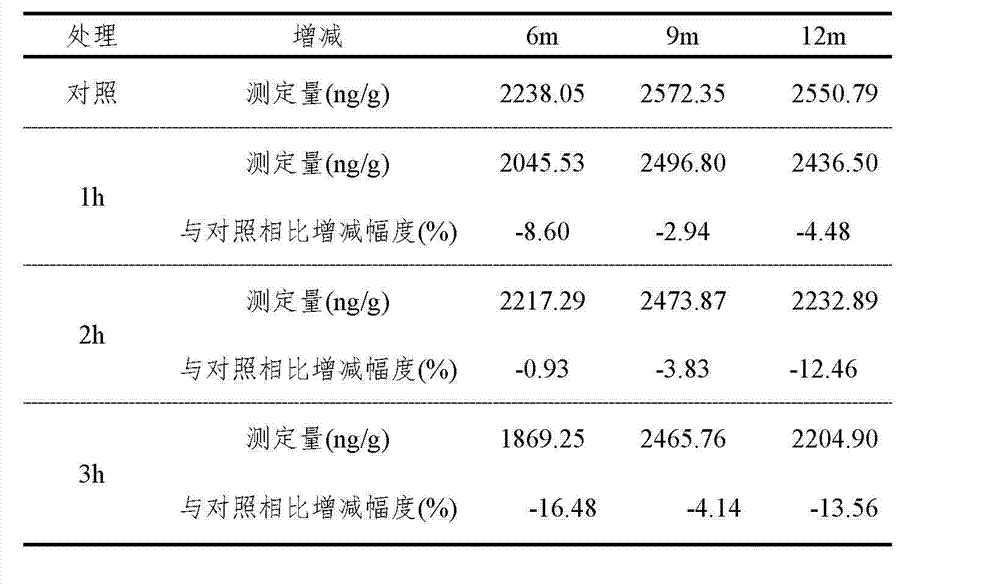

Embodiment 1

[0010] Cut the Burley tobacco leaf sample into shredded tobacco, remove impurities, sift out crushed tobacco and tobacco powder, mix evenly, and equilibrate at a temperature of 22±1°C and a humidity of 60±2% for 48 hours, and divide it into four parts. One was used as a control, and the other three were sealed with sample bags, and placed in a freezer at 0°C for 1 hour, 2 hours, and 3 hours, and then the control and each treated sample were taken out for alcoholization under the same conditions, and the samples of each treated tobacco leaf were monitored for 6 to 12 hours. The change of NNN content during the month aging process. It can be seen from Table 1 that compared with the control, the NNN content of the tobacco samples treated at 0°C for 1h, 2h and 3h all showed a decreasing trend during the aging process from 6 to 12 months, and the longer the treatment time, the greater the reduction rate. The largest is 3h (16.48%), followed by 2h (16.48%), and the smallest is 1h. ...

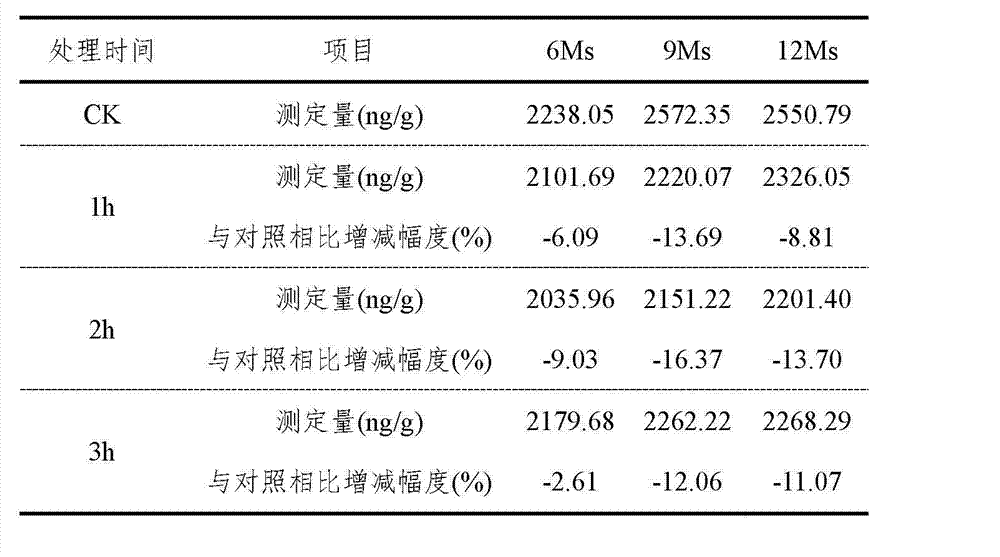

Embodiment 2

[0014] Cut the Burley tobacco leaf sample into shredded tobacco, remove impurities, sift out crushed tobacco and tobacco powder, mix evenly, and equilibrate at a temperature of 22±1°C and a humidity of 60±2% for 48 hours, and divide it into four parts. One was used as a control, and the other three were sealed with sample bags, and placed in a freezer at -20°C for 1h, 2h and 3h, then the control and each treated sample were taken out for alcoholization under the same conditions, and the tobacco leaf samples of each treatment were monitored for 6-6 hours. Changes in NNN content during 12-month aging. It can be seen from Table 2 that compared with the control, the NNN content of tobacco leaves treated at -20°C for 1h, 2h and 3h showed a decreasing trend from June to December, and the largest decrease was at 2h (about 10%), followed by 3h, the minimum is 1h; -20℃ treatment can reduce the NNN content by 16.37%. This indicated that the treatment of shredded tobacco at -20°C for 1h...

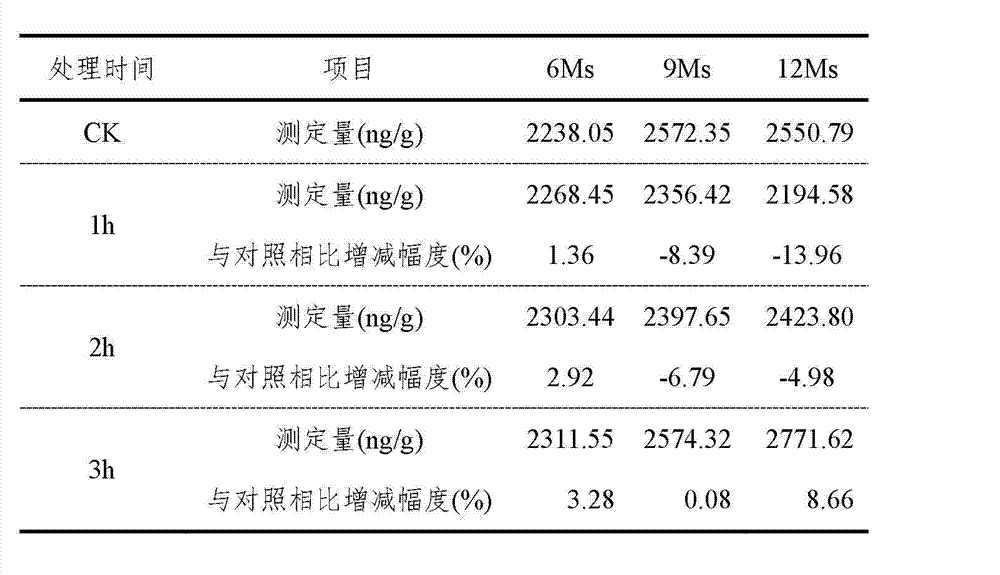

Embodiment 3

[0018] Cut Burley tobacco leaf samples into shredded tobacco, remove impurities, sift out crushed tobacco and tobacco dust, mix them evenly, and equilibrate them for 48 hours at a temperature of 22±1°C and a humidity of 60±2%, and divide them into four parts. One was used as a control, and the other three were sealed with sample bags, and placed in a freezer at -40°C for 1h, 2h and 3h, then the control and each treated sample were taken out for alcoholization under the same conditions, and the tobacco leaf samples of each treatment were monitored for 6-6 hours. Changes in NNN content during 12-month aging. It can be seen from Table 3 that compared with the control, under the condition of -40°C, only the NNN content of the 1h and 2h tobacco leaves showed a decreasing trend in September and December, and the rest of the treatments were higher than the control. This shows that the effect of reducing the NNN of shredded tobacco at -40℃ for 1h to 3h is not obvious.

[0019] Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com