Surface functionalization nanometer upconversion materials used for display of latent fingerprints

A conversion material and nanotechnology, applied in the direction of luminescent materials, material excitation analysis, application, etc., can solve the problems that the stability and reproducibility of the display effect cannot be guaranteed, and achieve the effect of easy operation and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

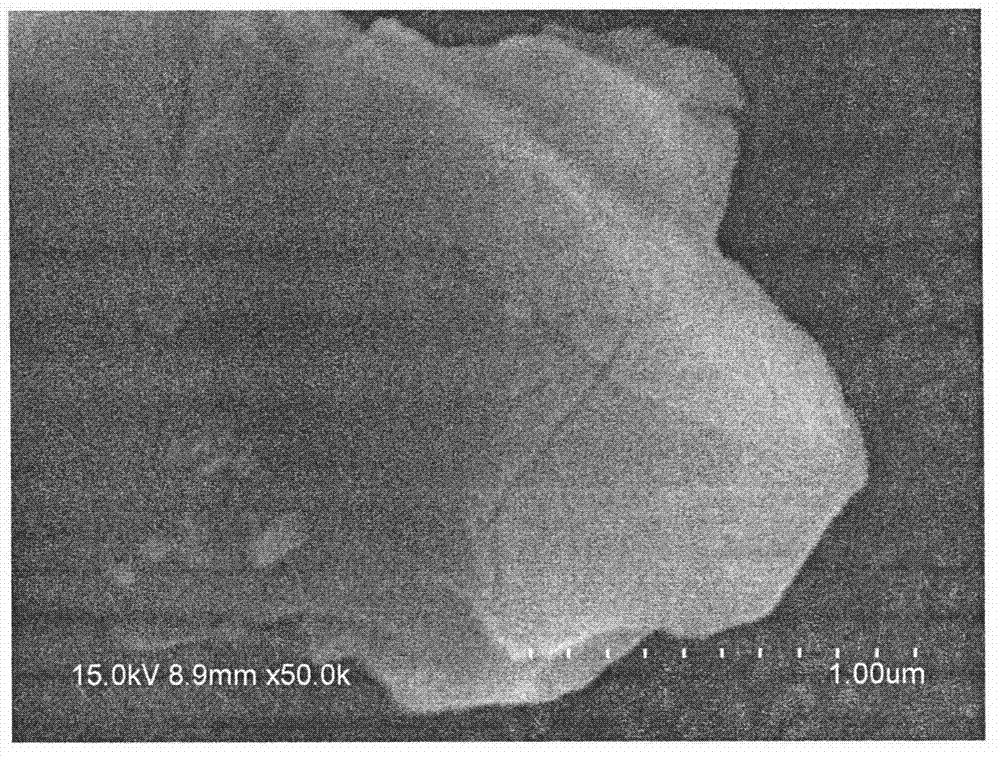

[0028] 1) 0.1 g of red nano-scale up-conversion material was alkalized in 0.5 mol / L NaOH solution for 4 hours with magnetic stirring, the supernatant was poured off by centrifugation, and the up-conversion material solution was washed with distilled water to pH 7.0. Then, it was stirred with 0.5 mol / L HCl solution for 0.5 hours, and after removing the supernatant, the up-conversion material was washed with distilled water to pH 6.5, and vacuum-dried at 120° C. to constant weight.

[0029] 2) Add 0.1 g of alkalized up-conversion material to 8 mL of absolute ethanol solution, adjust the pH to 3.0 with acetic acid, and add 0.01 g of 3-aminopropyltriethoxysilane ( KH550) solution, ultrasonically dispersed, reacted at 80°C for 8 hours, centrifuged to pour off the supernatant, washed the up-conversion material with distilled water for 3 times, and vacuum-dried at 120°C to constant weight.

[0030] 3) Disperse 0.5mL of 25% glutaraldehyde solution in 9.5mL of pH 6.0 phosphate buffer s...

Embodiment 2

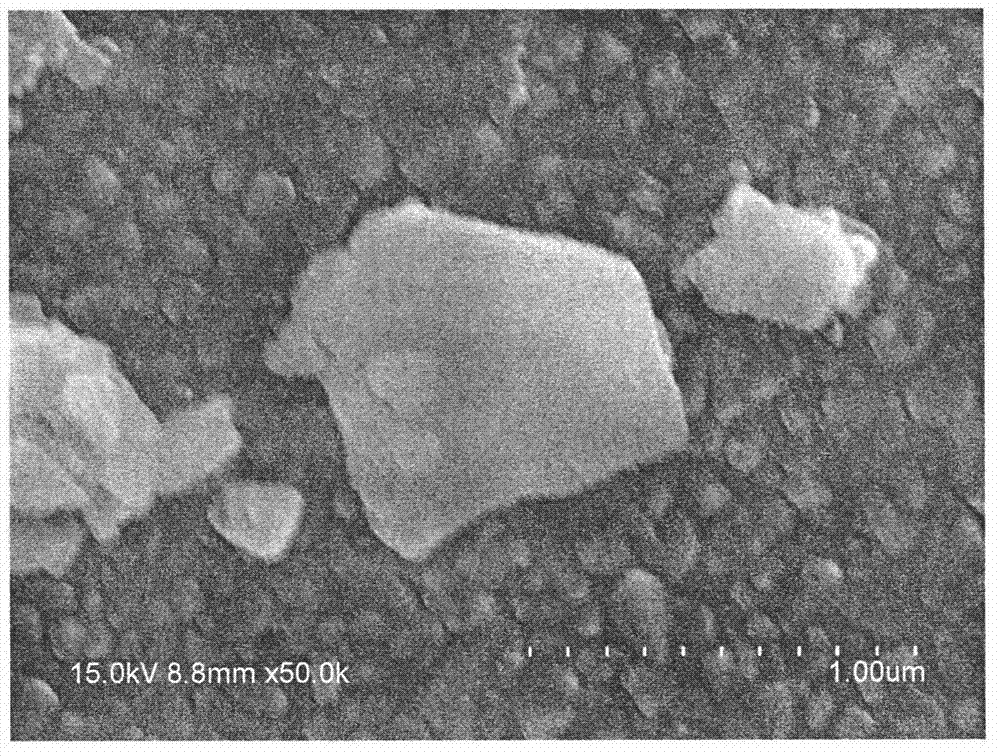

[0033]1) 0.1 g of red nano-scale up-conversion material was alkalized in 1.5 mol / L KOH solution for 3 hours with magnetic stirring, the supernatant was discarded by centrifugation, and the up-conversion material solution was washed to pH 6.8 with distilled water. Then, it was stirred with 2.0 mol / L HCl solution for 2 hours, and after the supernatant was poured off by centrifugation, the up-conversion material was washed to pH 6.8 with distilled water, and vacuum-dried at 120° C. to constant weight.

[0034] 2) Add 0.1 g of alkalized up-conversion material to 8 mL of absolute ethanol solution, adjust the pH to 4.0 with acetic acid, and add 0.02 g of 3-aminopropyltriethoxysilane ( KH550) solution, ultrasonically dispersed, reacted at 55°C for 11.5 hours, centrifuged to pour off the supernatant, washed the up-conversion material with distilled water for 3 times, and vacuum-dried at 120°C to constant weight.

[0035] 3) Disperse 0.134g of terephthalaldehyde in 10mL of PH7.0 phosph...

Embodiment 3

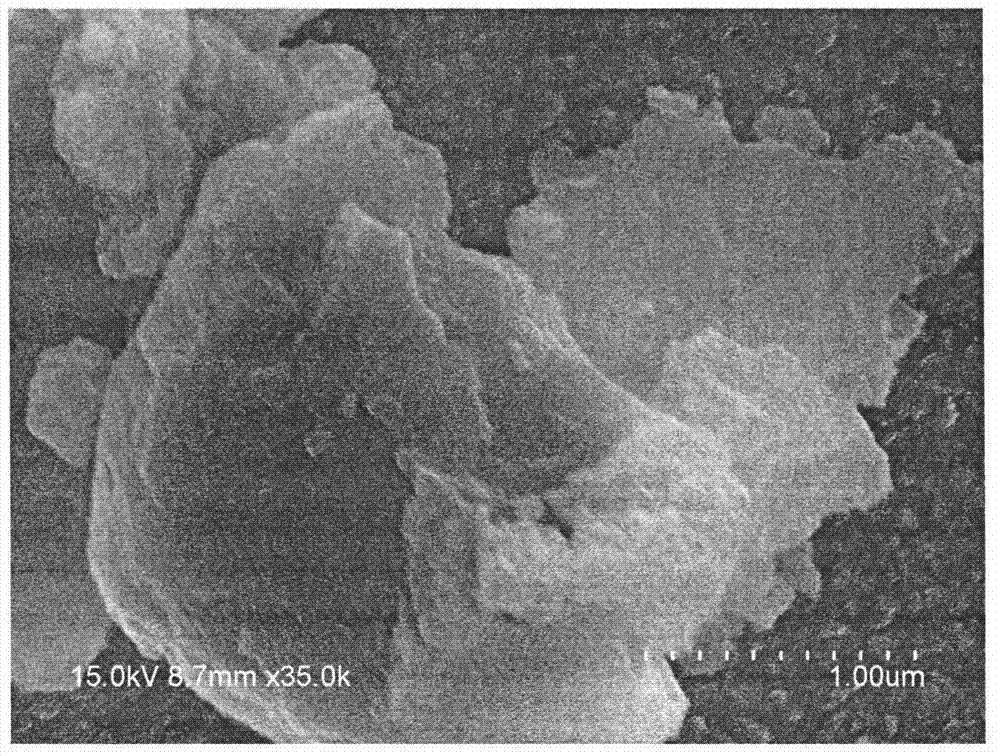

[0038] 1) 0.1 g of green nano-scale up-conversion material was alkalized in 2.0 mol / L NaOH solution for 2 hours with magnetic stirring, the supernatant was discarded by centrifugation, and the up-conversion material solution was washed to pH 6.5 with distilled water. Then, it was stirred with 1.5 mol / L HCl solution for 1.5 hours, and after centrifuging to pour off the supernatant, the up-conversion material was washed to pH 7.0 with distilled water, and vacuum-dried at 120° C. to constant weight.

[0039] 2) Add 0.1 g of alkalized up-conversion material to 8 mL of absolute ethanol solution, adjust the pH to 5.0 with acetic acid, and add 0.015 g of 3-aminopropyltriethoxysilane ( KH550) solution, ultrasonically dispersed, reacted at 30°C for 15 hours, centrifuged to pour off the supernatant, washed the up-conversion material with distilled water for 3 times, and vacuum-dried at 120°C to constant weight.

[0040] 3) Disperse 0.2g o-phthalaldehyde solution in 10mL pH 8.0 phosphate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com