Method for determining five stand tandem cold mill depressing distribution

A cold tandem mill, cold tandem technology, applied in the direction of rolling force/roll gap control, etc., can solve the problems of lack of flexibility, complex calculation process, difficult solution, etc., to achieve the effect of easy operation, easy implementation and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] This embodiment discloses a method for determining the distribution of reductions in a five-stand cold rolling mill in a process control system of a five-stand cold rolling mill. Products that can be rolled by this rolling mill include plain carbon steel, high-strength steel, etc. What the present embodiment rolls is common carbon steel.

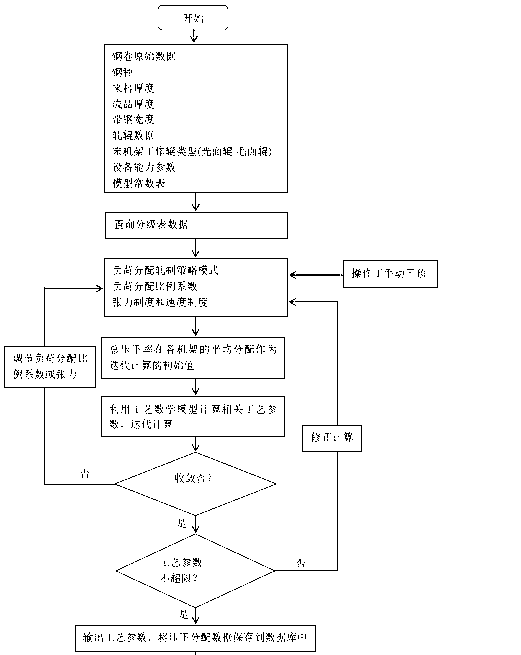

[0041] The method for determining the reduction distribution of a five-stand tandem cold rolling mill provided in this embodiment is as follows: figure 1 shown, including the following steps:

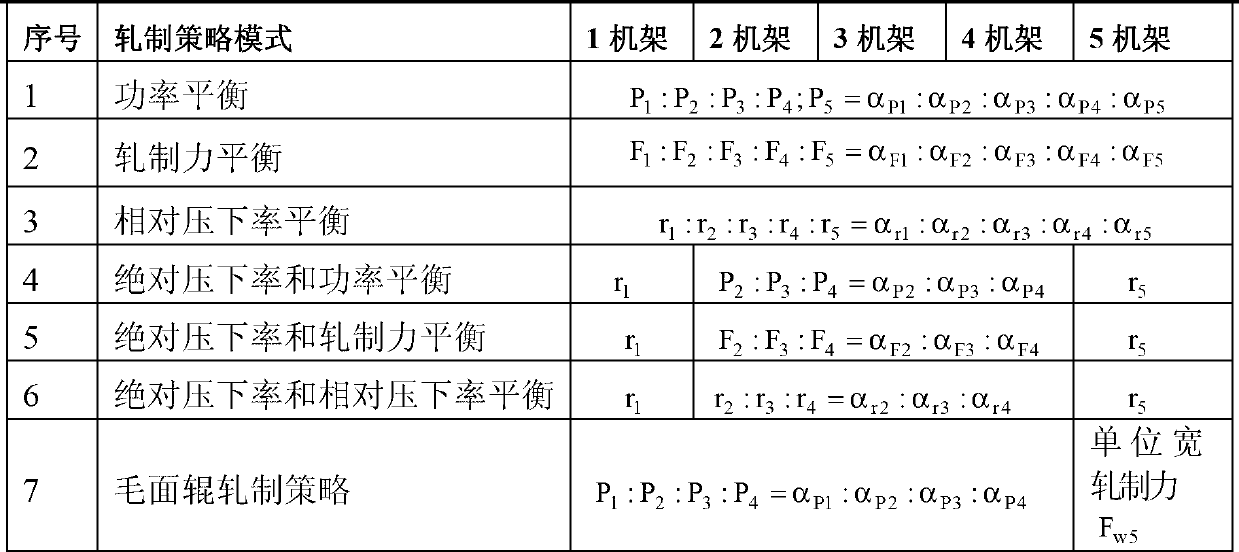

[0042] Step 1, according to the technical characteristics of the cold tandem rolling mill and the varieties and specifications rolled, a classification table and a rolling strategy mode for pressing and distributing are established;

[0043] First, create various grading tables;

[0044] Steel code table (STEEL_CODE)

[0045] material code

Steel grade

steel type

1

Q195

CQ

2

Q215

CQ

3

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com