Patents

Literature

85 results about "Quasi-Newton method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quasi-Newton methods are methods used to either find zeroes or local maxima and minima of functions, as an alternative to Newton's method. They can be used if the Jacobian or Hessian is unavailable or is too expensive to compute at every iteration. The "full" Newton's method requires the Jacobian in order to search for zeros, or the Hessian for finding extrema.

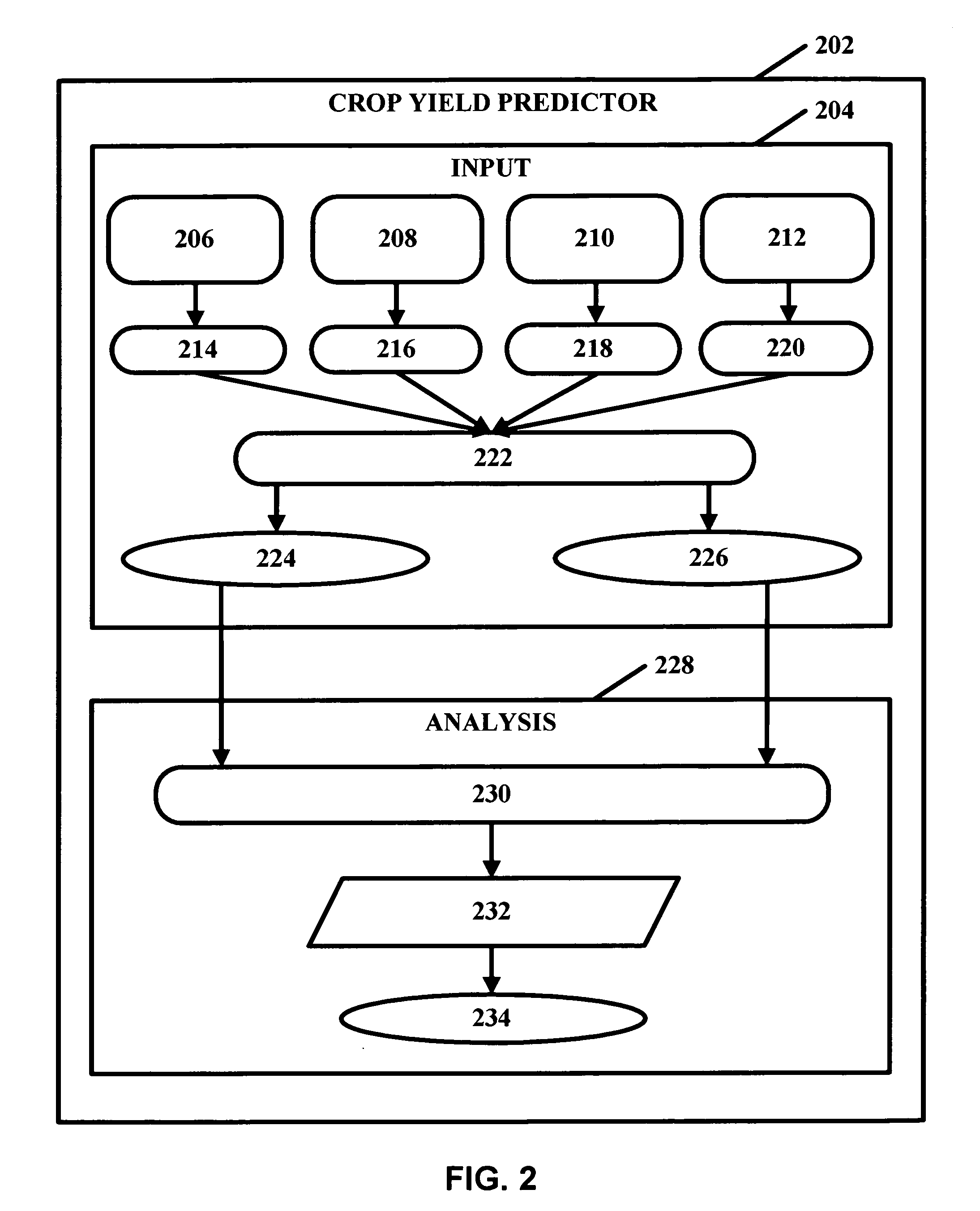

Crop yield prediction

InactiveUS20050234691A1Climate change adaptationAnalogue computers for chemical processesNon linear methodsEngineering

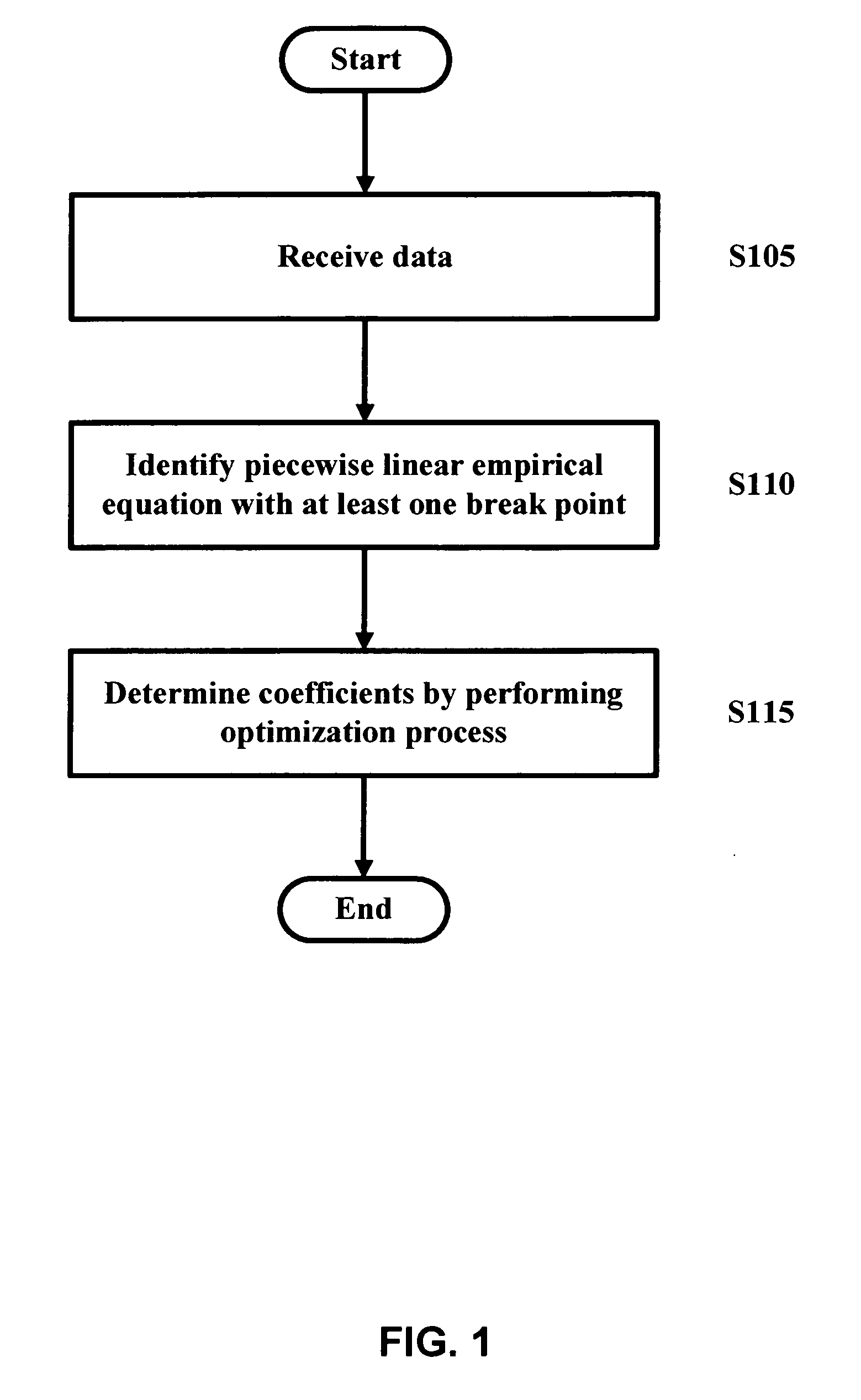

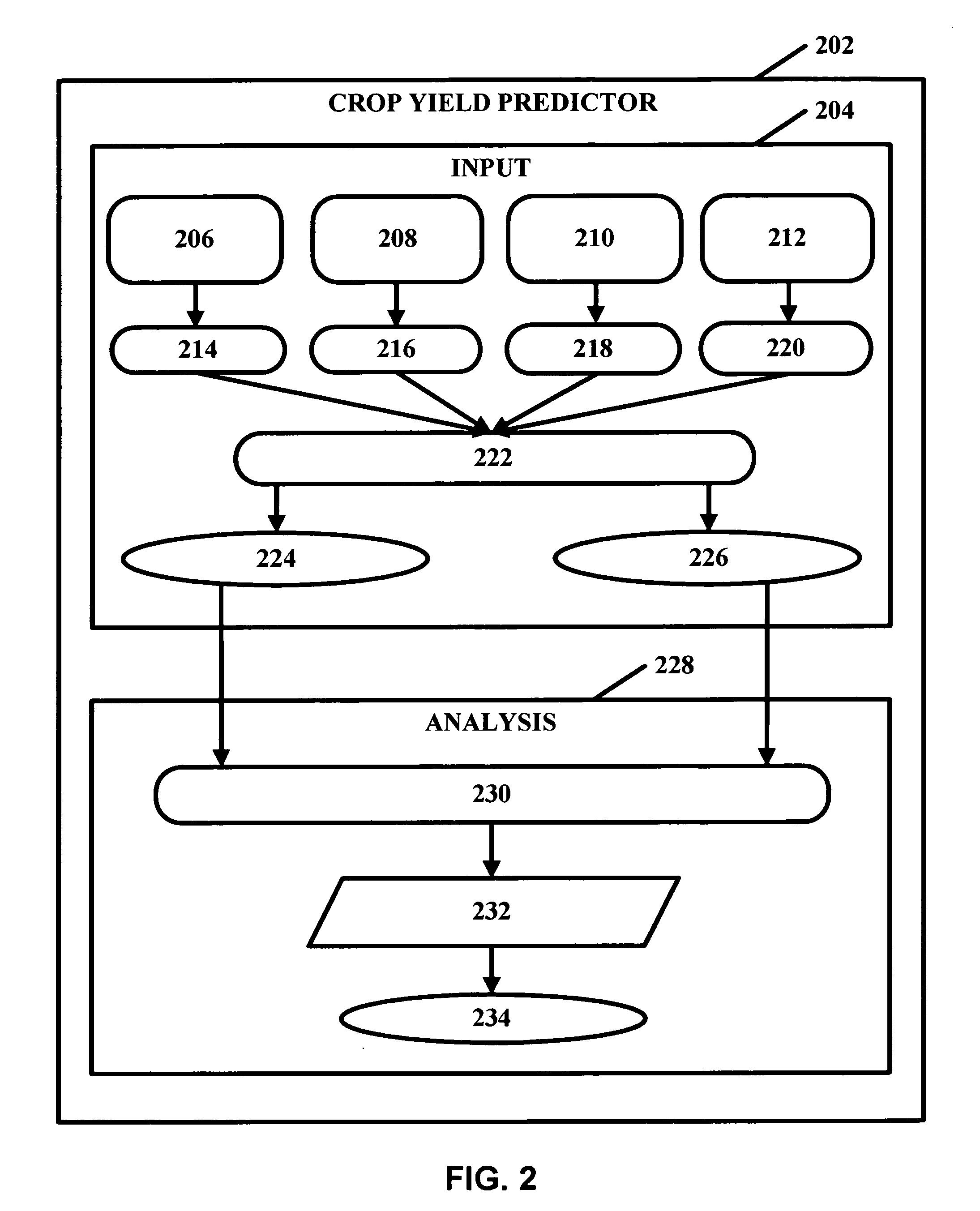

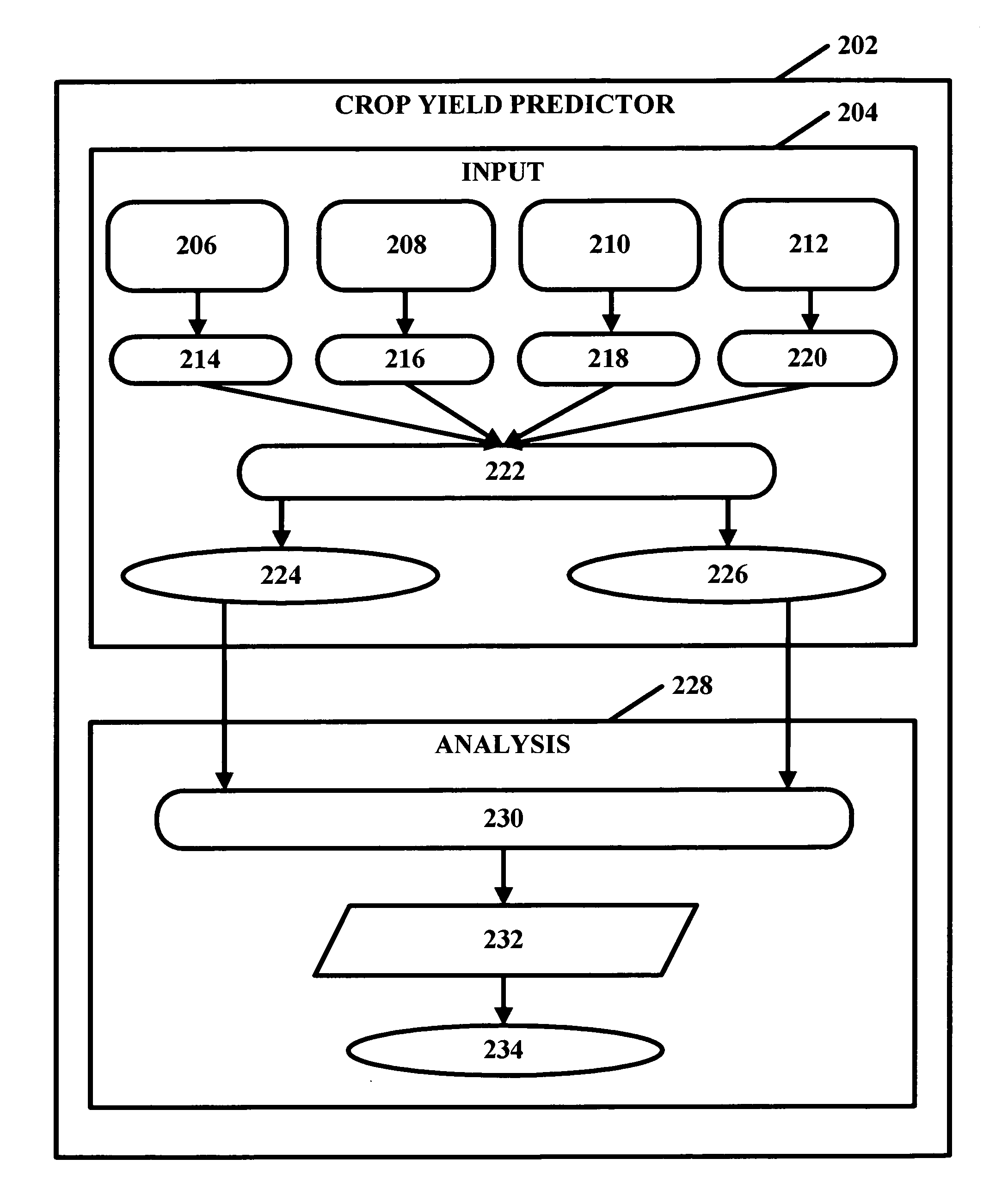

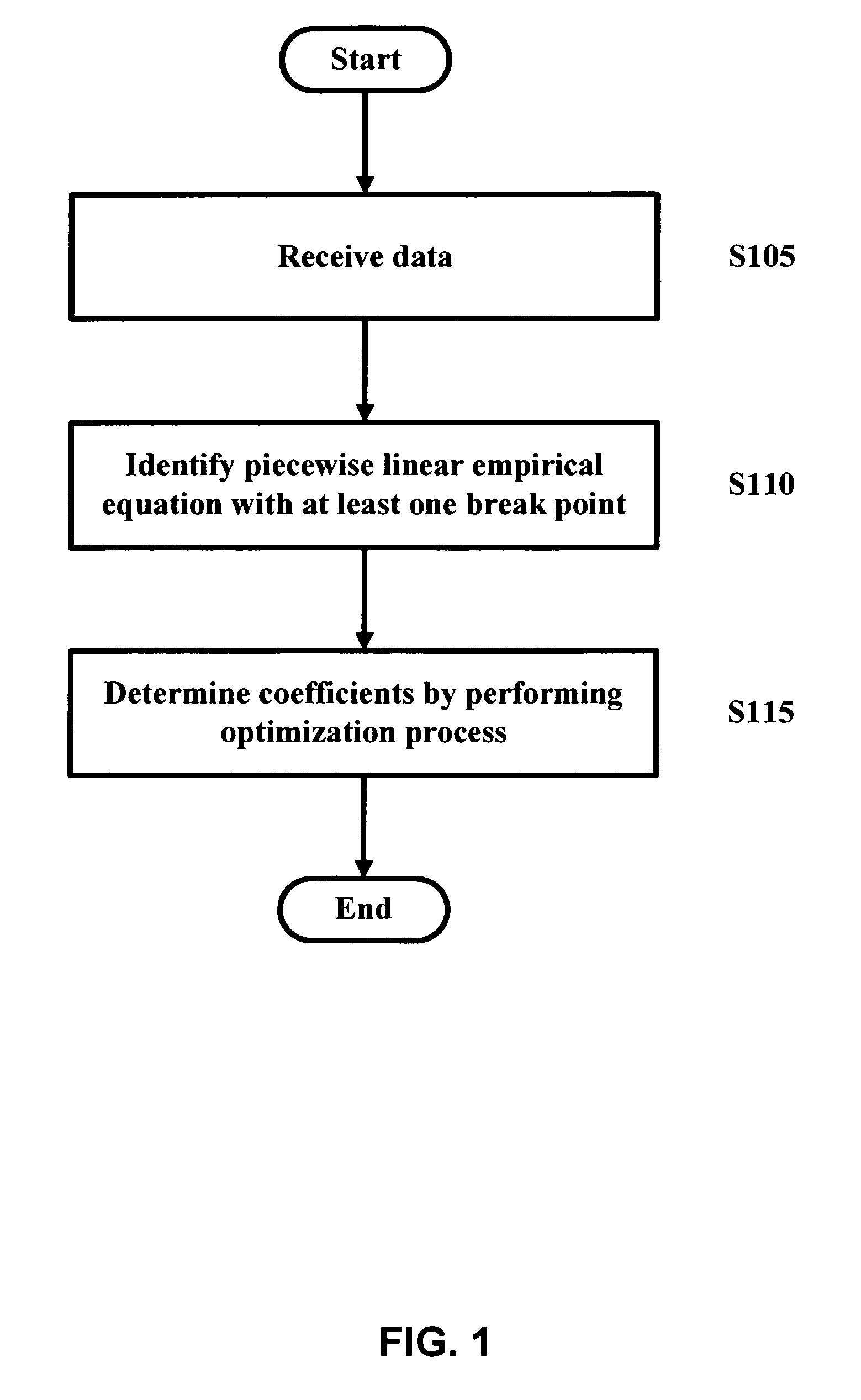

Crop yield may be assessed and predicted using a piecewise linear regression method with break point and various weather and agricultural parameters, such as NDVI, surface parameters (soil moisture and surface temperature) and rainfall data. These parameters may help aid in estimating and predicting crop conditions. The overall crop production environment can include inherent sources of heterogeneity and their nonlinear behavior. A non-linear multivariate optimization method may be used to derive an empirical crop yield prediction equation. Quasi-Newton method may be used in optimization for minimizing inconsistencies and errors in yield prediction. Minimization of least square loss function through iterative convergence of pre-defined empirical equation can be based on piecewise linear regression method with break point. This non-linear method can achieve acceptable lower residual values with predicted values very close to the observed values. The present invention can be modified and tailored for different crops worldwide.

Owner:GEORGE MASON INTPROP INC

Parallelized human body behavior identification method

InactiveCN104899561AIncrease training rateReduce generationCharacter and pattern recognitionExtensibilityHuman body

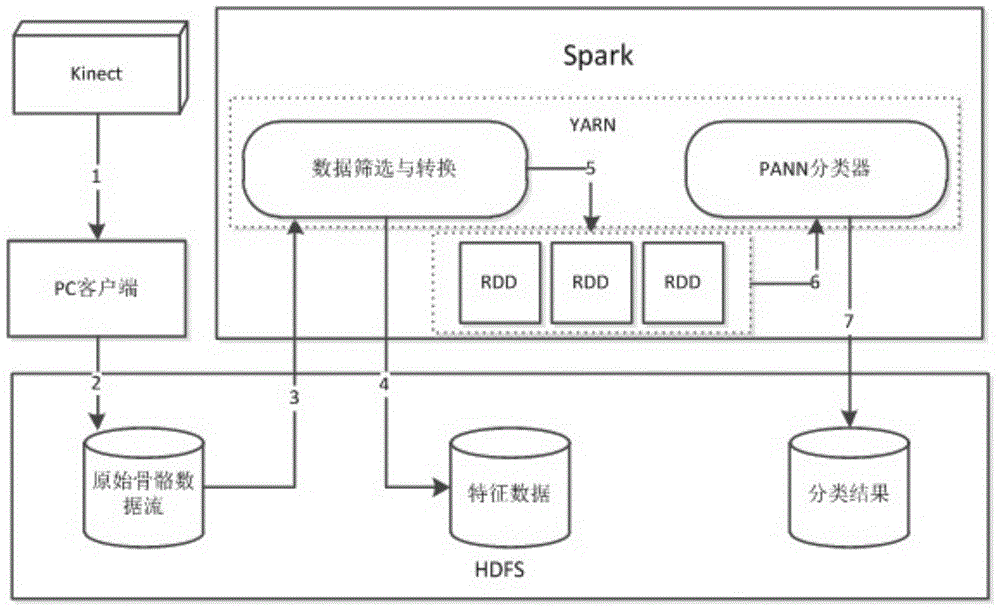

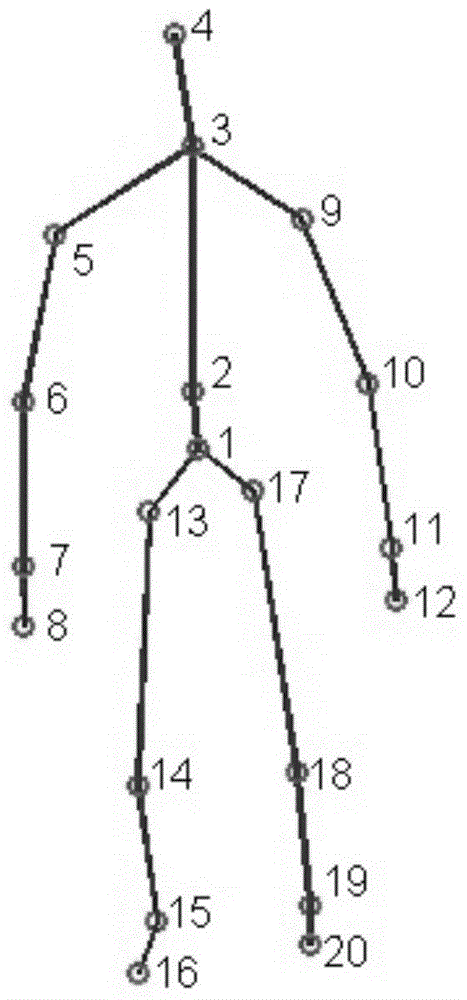

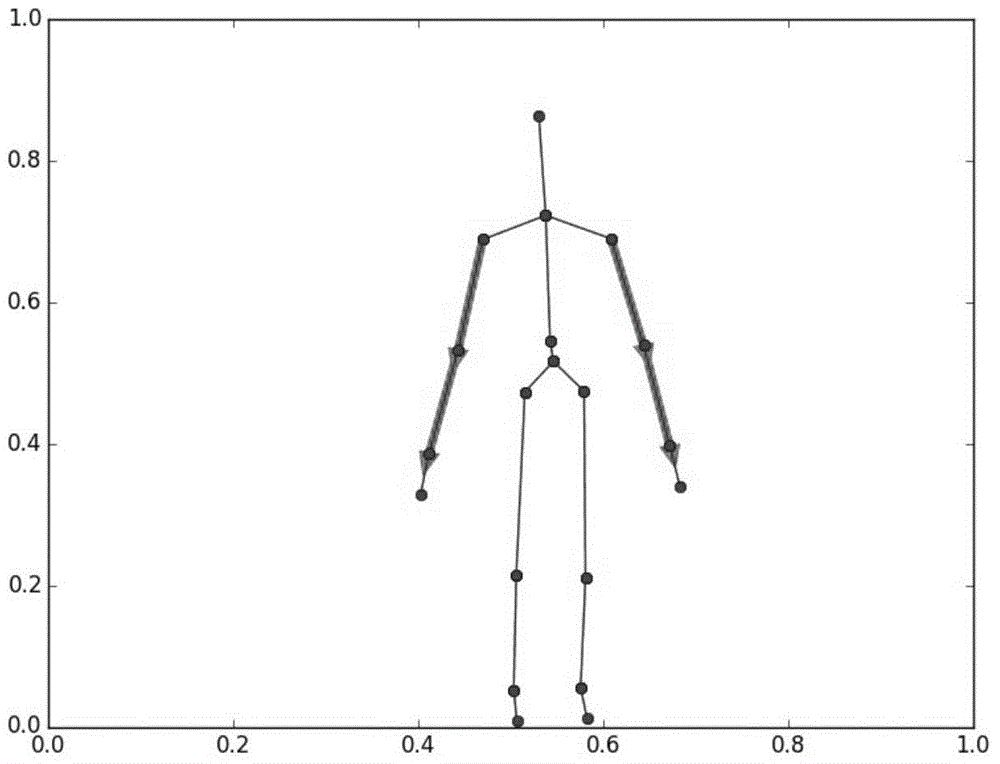

The present invention discloses a parallelized human body behavior identification method. According to the method, skeleton data of Kinect is used as input; a distributed behavior identification algorithm is implemented based on a Spark computing framework; and a complete parallel identifying process is formed. Acquisition of the skeleton data of a human body is based on scene depth acquisition capacity of Kinect and the data is preprocessed to ensure invariability of displacement and scale of characteristics; and a human body structural vector, joint included angle information and skeleton weight bias are respectively selected for static behavior characteristics and a dynamic behavior searching algorithm for a structural similarity is provided. On the identification algorithm, a neural network algorithm is parallelized on Spark; a quasi-newton method L-BFGS is adopted to optimize a network weight updating process; and the training speed is obviously increased. According to an identification platform, a Hadoop distributed file system HDFS is used as a behavior data storage layer; Spark is applied to a universal resource manager YARN; the parallel neural network algorithm is used as an upper application; and the integral system architecture has excellent extendibility.

Owner:SOUTH CHINA UNIV OF TECH

Crop yield prediction using piecewise linear regression with a break point and weather and agricultural parameters

InactiveUS7702597B2Climate change adaptationAnalogue computers for chemical processesMultivariable optimizationNon linear methods

Owner:GEORGE MASON INTPROP INC

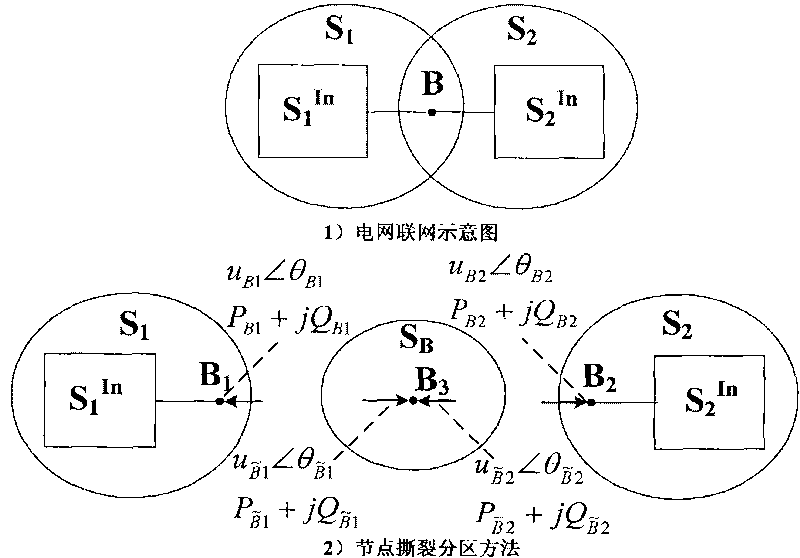

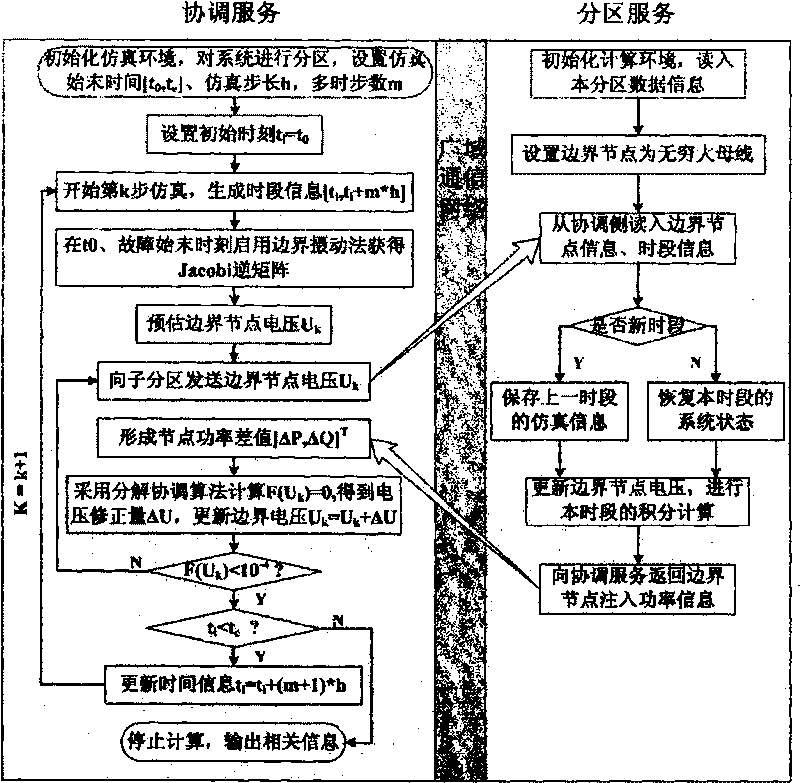

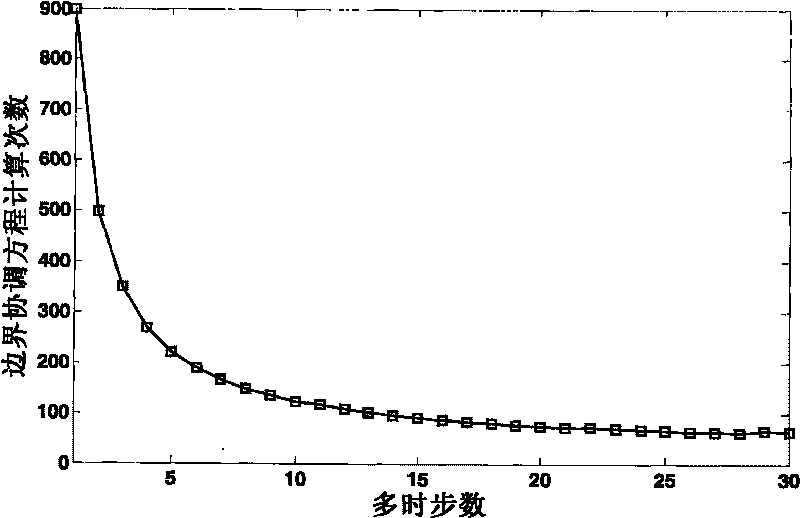

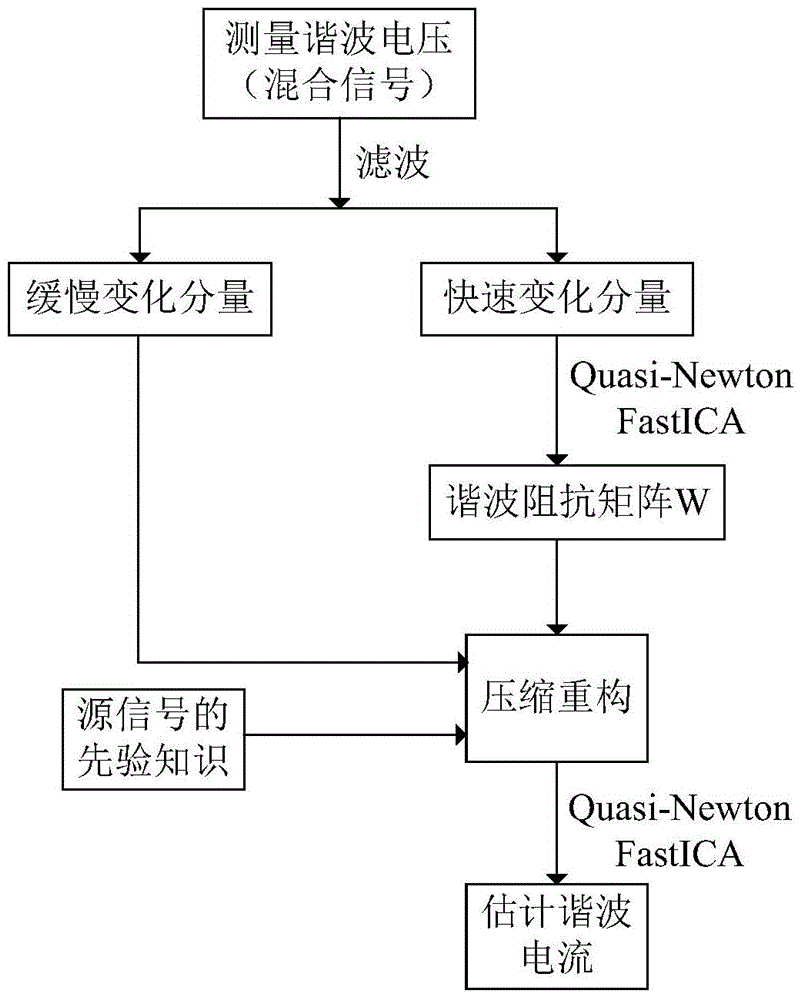

Transient stability distributed simulation method of electric power system

ActiveCN101699448AFast convergenceKeep Data Interface SimpleSpecial data processing applicationsInformation technology support systemEngineeringTransient stability analysis

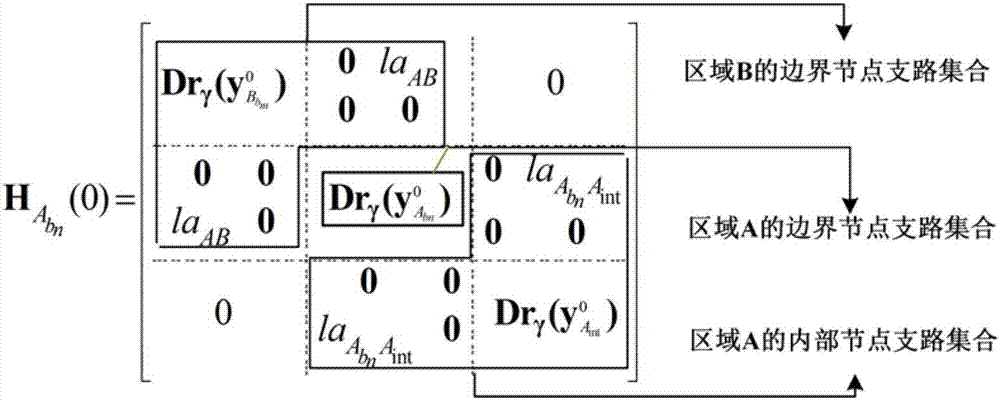

The invention relates to a transient stability distributed simulation method of an electric power system, belonging to the transient stability analysis technical field of the electric power system; the transient stability distributed simulation method is characterized in that: variable dimension of boundary coordination equation is reduced to one half of that of a partitioning method based on connecting line by using the partitioning method based on a node decomposing method, so as to improve the simulation efficiency; the accurate initial Jacobi inverse matrix is obtained by using a boundary perturbation method, so as to reduce iterations; the calculation process is accelerated by comprehensively adopting the methods that the boundary node voltage value of the next time step is pre-estimated and the Jacobi inverse matrix is coordinated and dynamically updated simultaneously in multiple time steps; by adopting coordination algorithm based on inverse Broyden quasi-Newton method, the solving times of the boundary coordination equation are reduced greatly, so as to improve the simulation efficiency. In the technical proposal, the data interface is simple, the data transmission capacity is low, the system model is simplified, superlinear convergence speed close to the newton method is provided, and hyper real-time simulation can be realized in a wide area communication network, therefore, the method is conveniently applied to the practical electric power system.

Owner:TSINGHUA UNIV

Signal source positioning method based on BFGS quasi-Newton method

InactiveCN103135094AOvercome errorHigh positioning accuracyPosition fixationObservational errorMultilateration

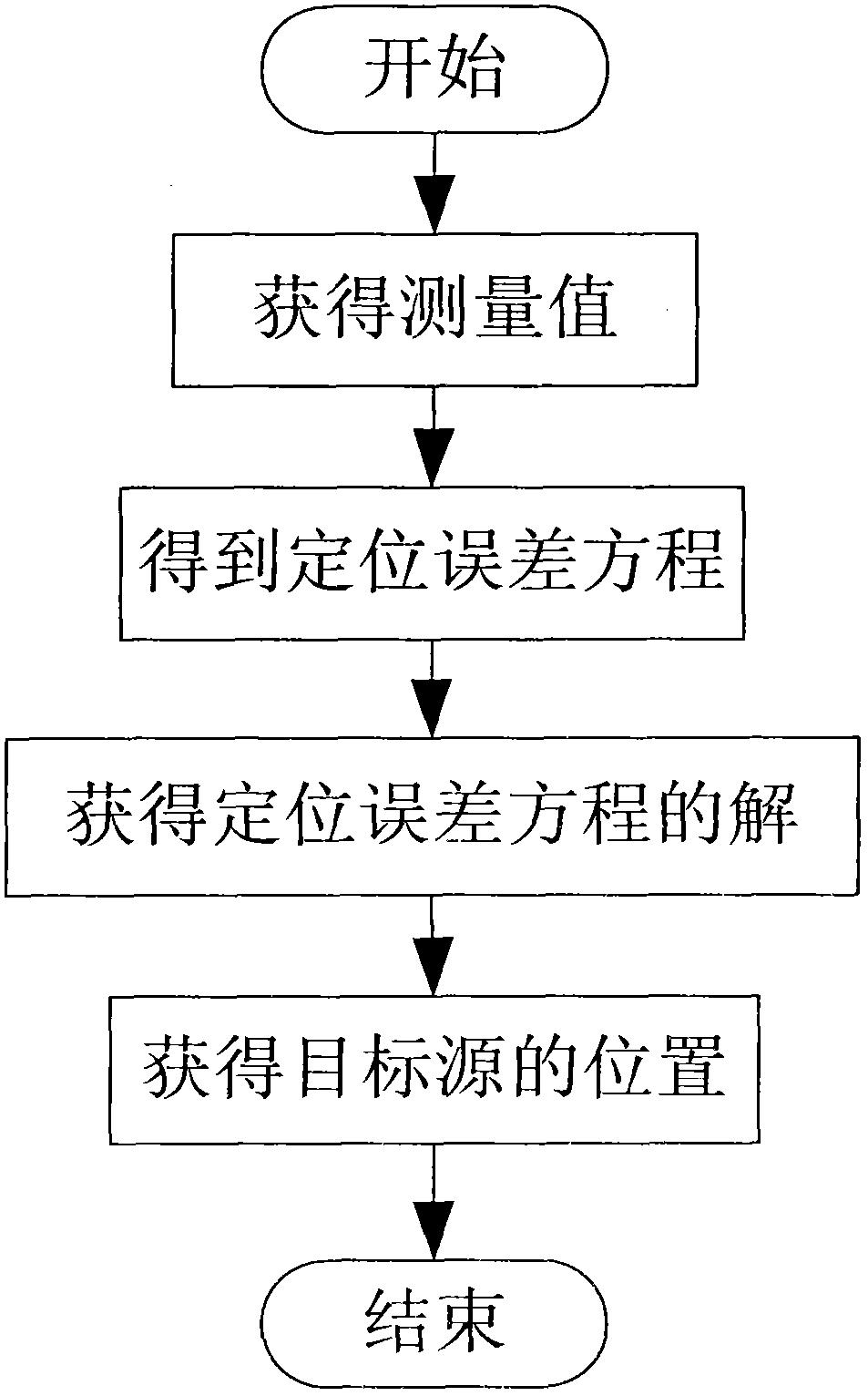

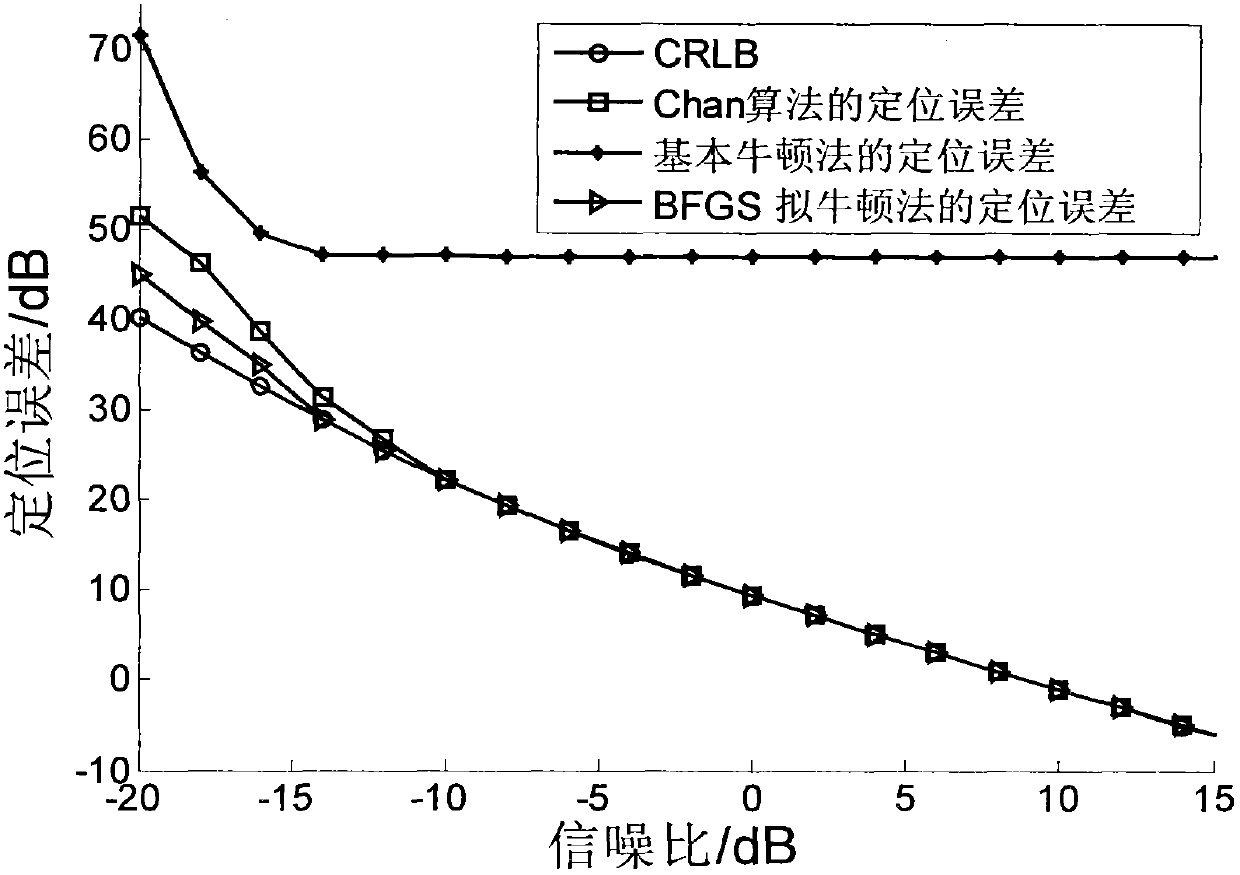

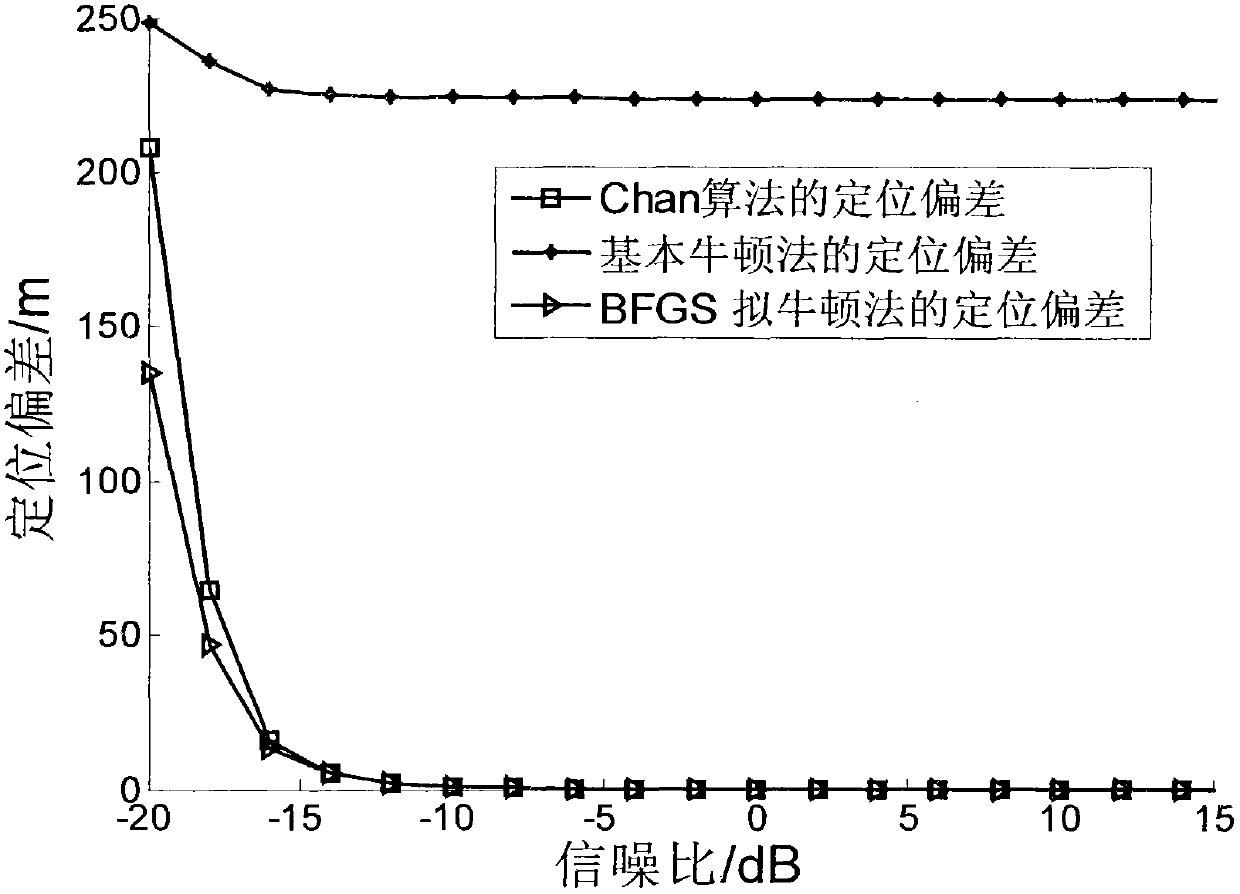

The invention discloses a signal source positioning method based on a BFGS quasi-Newton method and mainly aims to solve the problems that median error is introduced in an existing positioning method, positioning results are fuzzy, practicality is not strong, calculation amount is large, positioning results are not stable and the like. The signal source positioning method based on the BFGS quasi-Newton method comprises the following steps of obtaining a measured value reaching time difference and a measured value reaching gain ratio; setting joint positioning error equations through the relationship that the measured valve minus measured error is a real value; obtaining solution of the positioning error equations through the BFGS quasi-Newton method; and obtaining position coordinate values of a target source through the fact that the solution of the positioning error equations plus position coordinate values of a reference monitor node. According to the signal source positioning method based on the BFGS quasi-Newton method, stable and high precision positioning is achieved. The signal source positioning method based on the BFGS quasi-Newton method is suitable for the environment with low signal-noise rate and strong in practicability.

Owner:XIDIAN UNIV

An oral cavity soft and hard tissue CT sequence and three-dimensional grid model registration method

ActiveCN105279762AImprove registration accuracyOptimal registration positionImage enhancementImage analysisThree-dimensional spaceEnergy functional

The invention provides an oral cavity soft and hard tissue CT sequence and three-dimensional grid model registration method comprising the following steps of: firstly manually dividing a biting impression model to obtain the part without a pedestal in the biting impression model; secondly, according to rough tooth outlines of user editing and calibrating, dividing input CT sequences to obtain the coordinates of the tooth outlines in the CT sequences, and constructing a hard tissue point set with the point coordinates of tooth hard tissue outlines of input layers of CT sequences; thirdly using iterative closest point algorithm for registration of the point set coordinates of the biting impression model and the point set coordinates of the hard tissue outlines to obtain the rough registration position in three-dimensional space of the biting impression model; fourthly, using the rough registration position obtained through the ICP algorithm as the initial result of accurate registration, constructing initial energy function values for the given CT sequences and the position of a three-dimensional grid model of initial registration, and optimizing the energy function through the quasi-Newton method to obtain an accurate registration result. The method enables superposition display of registration of CT sequences and biting impression models and can measure the thickness of soft tissue in CT sequences.

Owner:BEIHANG UNIV +1

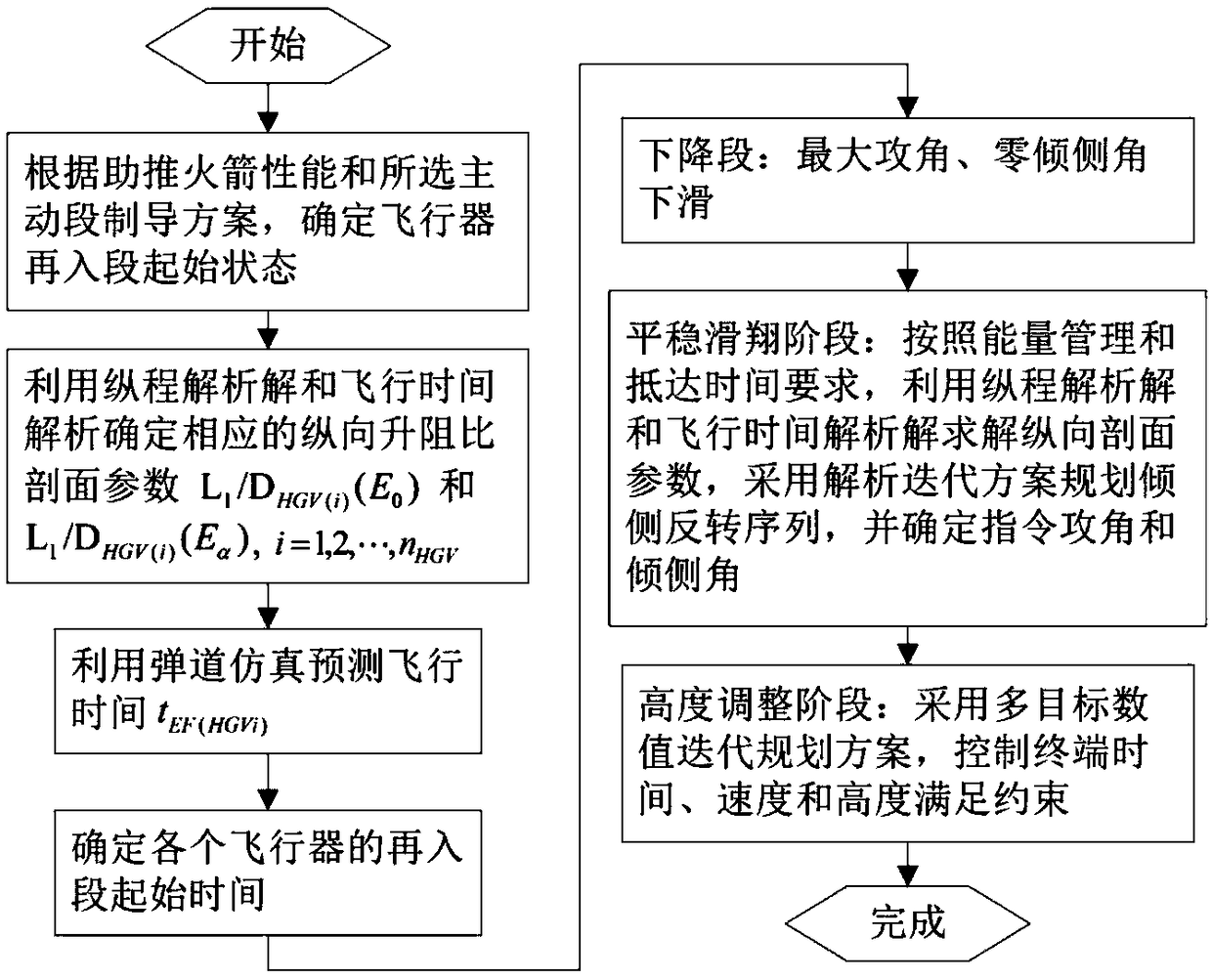

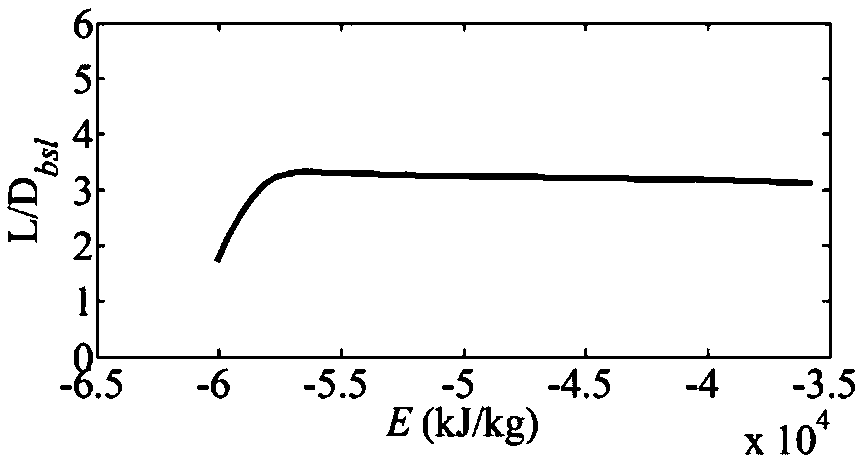

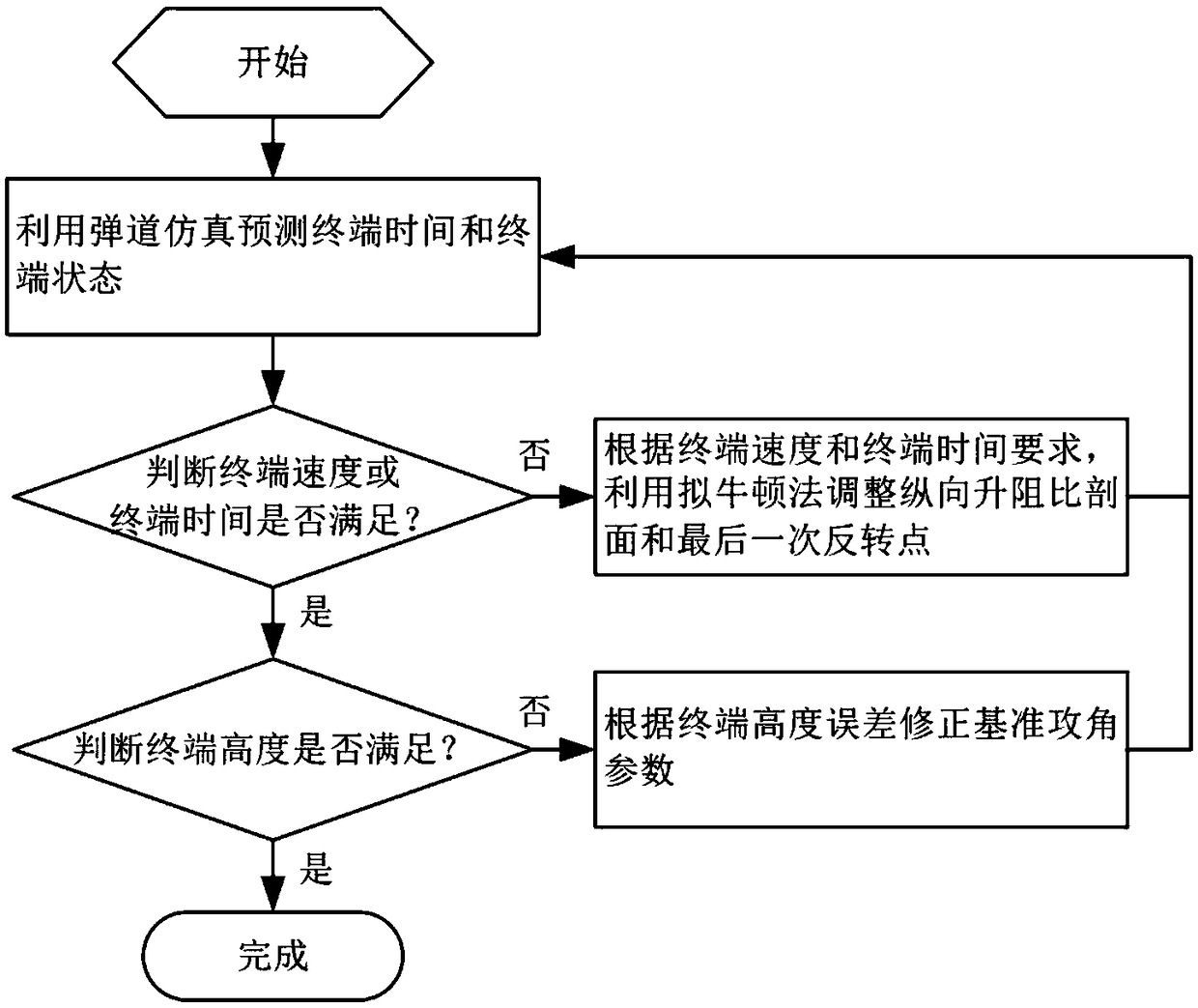

Collaborative analysis reentry guidance method considering multiple no-fly zone constraint

ActiveCN109508030ALarge prediction errorBig errorPosition/course control in three dimensionsNo-fly zoneSimulation

The invention relates to a collaborative analysis reentry guidance method considering multiple no-fly zone constraint, which comprises the steps of 1, describing a reentry guidance problem; 2, providing an analytic solution of flight time based on a rotational globe model; 3, carrying out an analytic reentry guidance process considering multiple no-fly zone and arrival time constraint; 4, providing a multi-aircraft arrival time collaboration scheme. The method herein has the advantages that an exact analytic solution of hypersonic gliding trajectory flight time based on the rotational globe model, and a prediction error is kept less than 3% to adapt to conditions with non-constant vertical lift-drag ratio profile; the problem with collaborative flight allowing multiple hypersonic gliding aircrafts to be guided to arrive at a target at the same time in a multiple no-fly zone environment is solved on the basis of the analytic solution of three-dimensional reentry trajectory and the analytic solution of flight time; a multi-target numeric iteration plan based on online trajectory simulation considering terminal time, speed and height requirements is designed. A directional derivativeis sued to modify the quasi-newton method, and the quantity of trajectory simulations is decreased.

Owner:BEIHANG UNIV

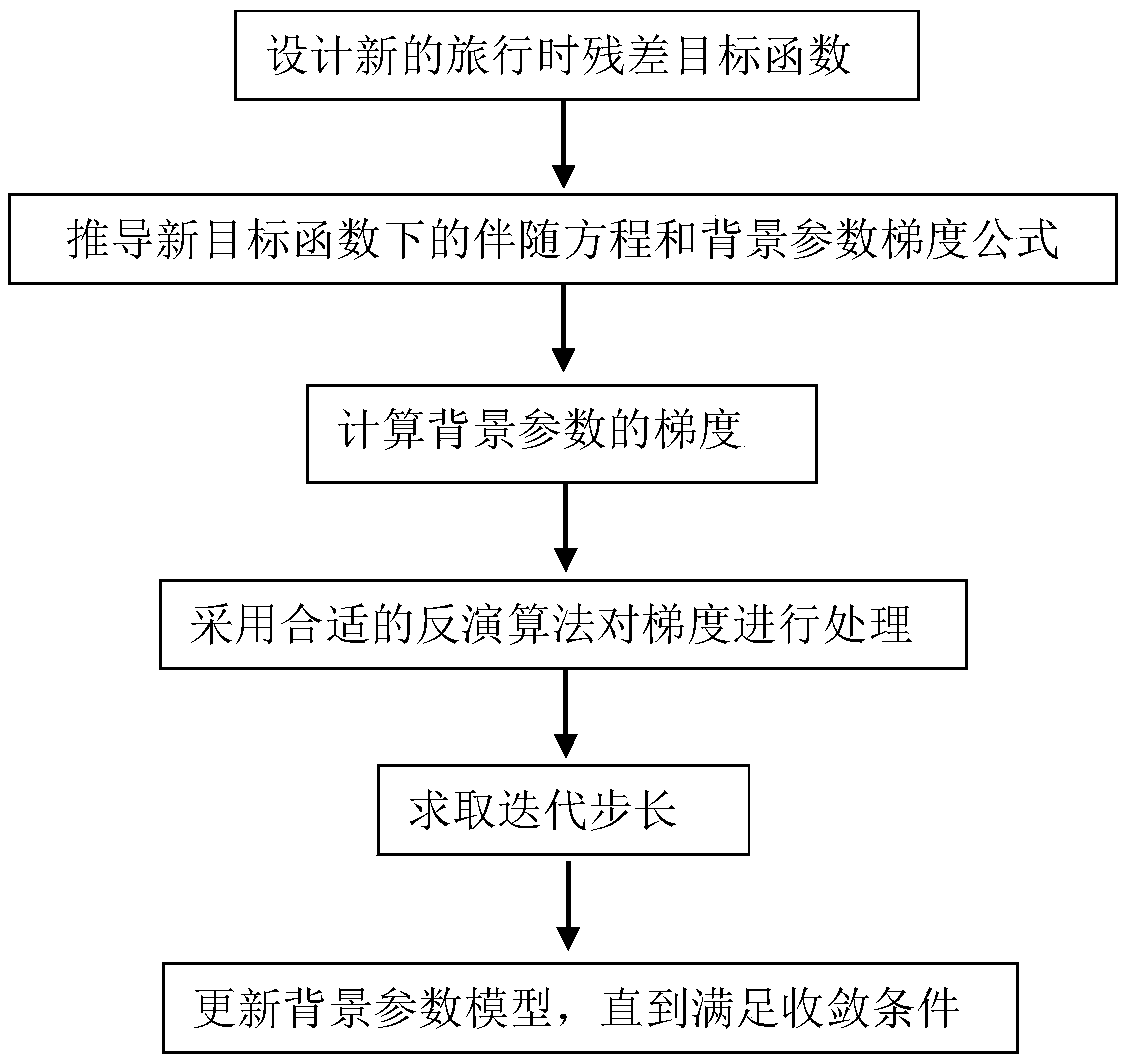

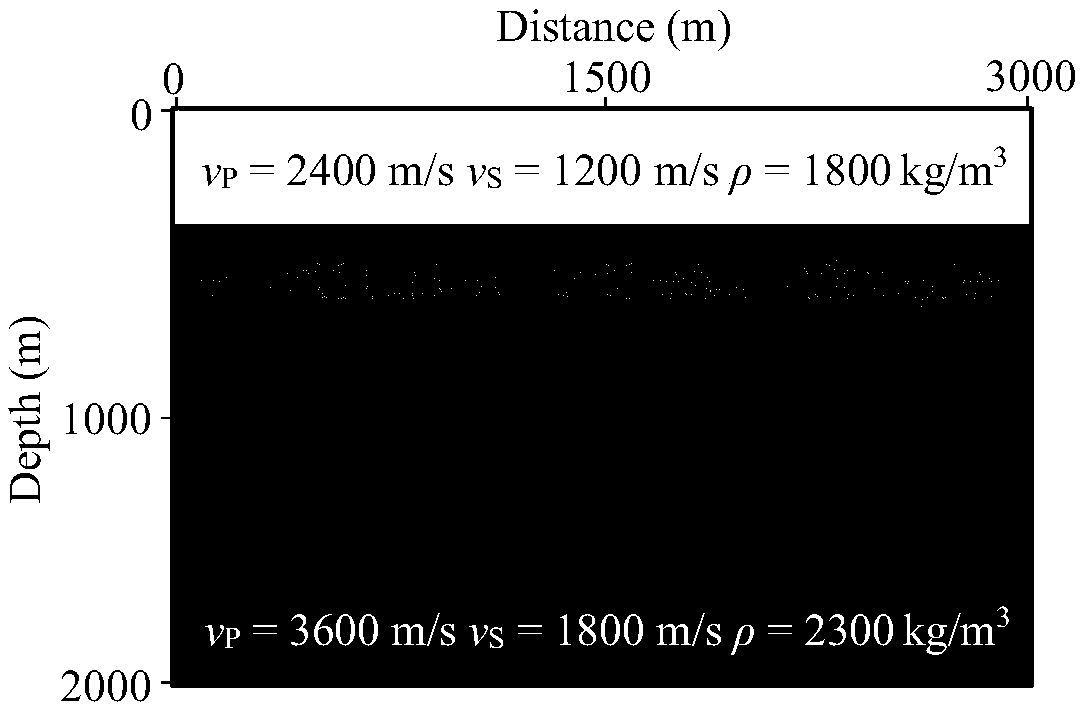

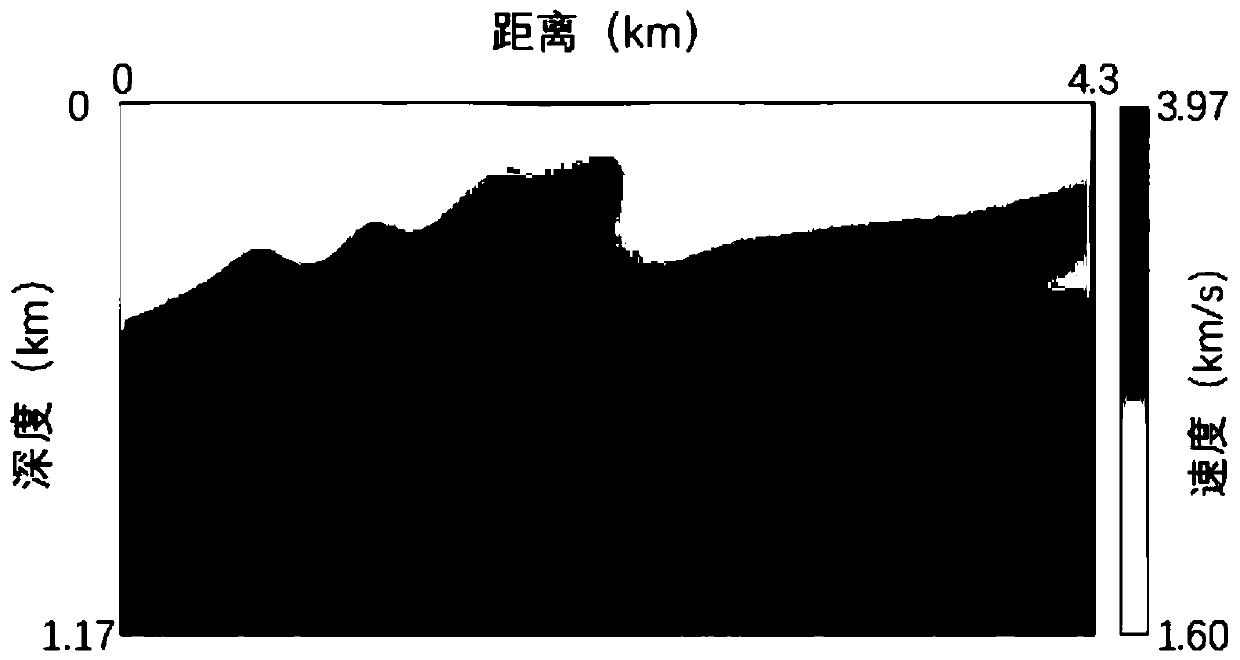

Elastic medium wave equation return wave travel time retrieval method

The invention provides an elastic medium wave equation return wave travel time retrieval method. The method comprises the steps of designing a new travel time residual target function; deducing an adjoint equation and a background parameter gradient formula under the new target function; calculating the gradient of background parameters; processing the gradient by using the quasi-Newton method retrieval algorithm; calculating the iteration step size by using the parabola fitting method; updating a background parameter model until the convergence condition is met. The method has the advantage that the precision of elastic medium return waveform retrieval is improved by using the new travel-time target function, so that reliable longitudinal wave velocity and transverse wave velocity initialmodels can be obtained.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

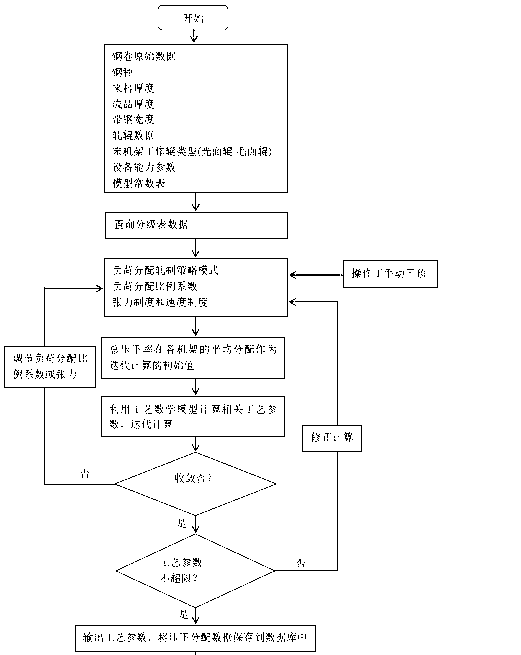

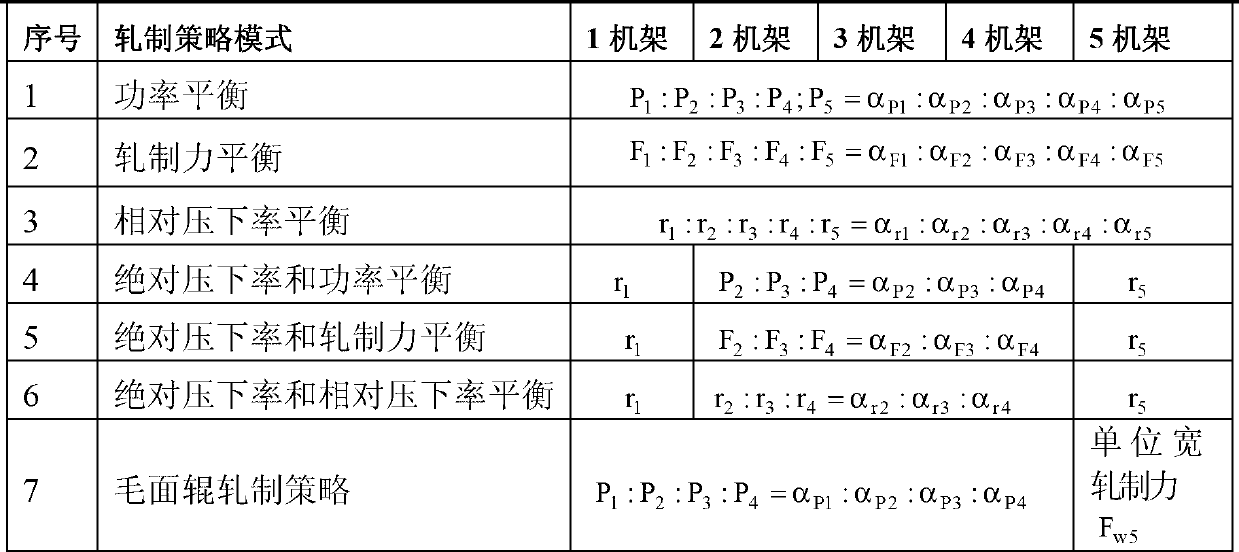

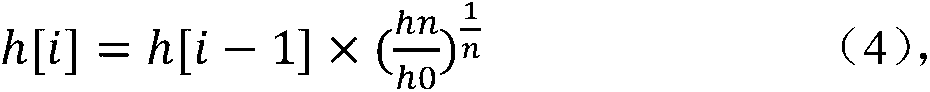

Method for determining five stand tandem cold mill depressing distribution

InactiveCN102921743AThe principle is simpleEasy to implementRoll force/gap control deviceOriginal dataNonlinear systems of equations

The invention provides a method for determining five stand tandem cold mill depressing distribution. The method comprises steps of designing rolling strategy modes and various grading forms which are suitable to a tandem cold mill in accordance with process requirements of the tandem cold mill and original data of coils, selecting data of grading forms and device parameters of the mill of a device capability form in accordance with selected depressing distribution rolling strategy modes and depressing distribution proportionality coefficients, setting up a depressing distribution calculation model, calculating rolling process parameters by using a rolling process mathematical model, solving a non-linear equation model through a quasi-Newton method, calculating obtained satisfied depressing distribution, storing the depressing distribution data to a database, and preparing data for setting a calculation model. According to process properties of the tandem cold mill, the proper rolling strategy modes are provided, the depressing distribution calculation model is set up, the principle is simple, the implementation is easy and the operation is convenient.

Owner:中冶南方(武汉)信息技术工程有限公司

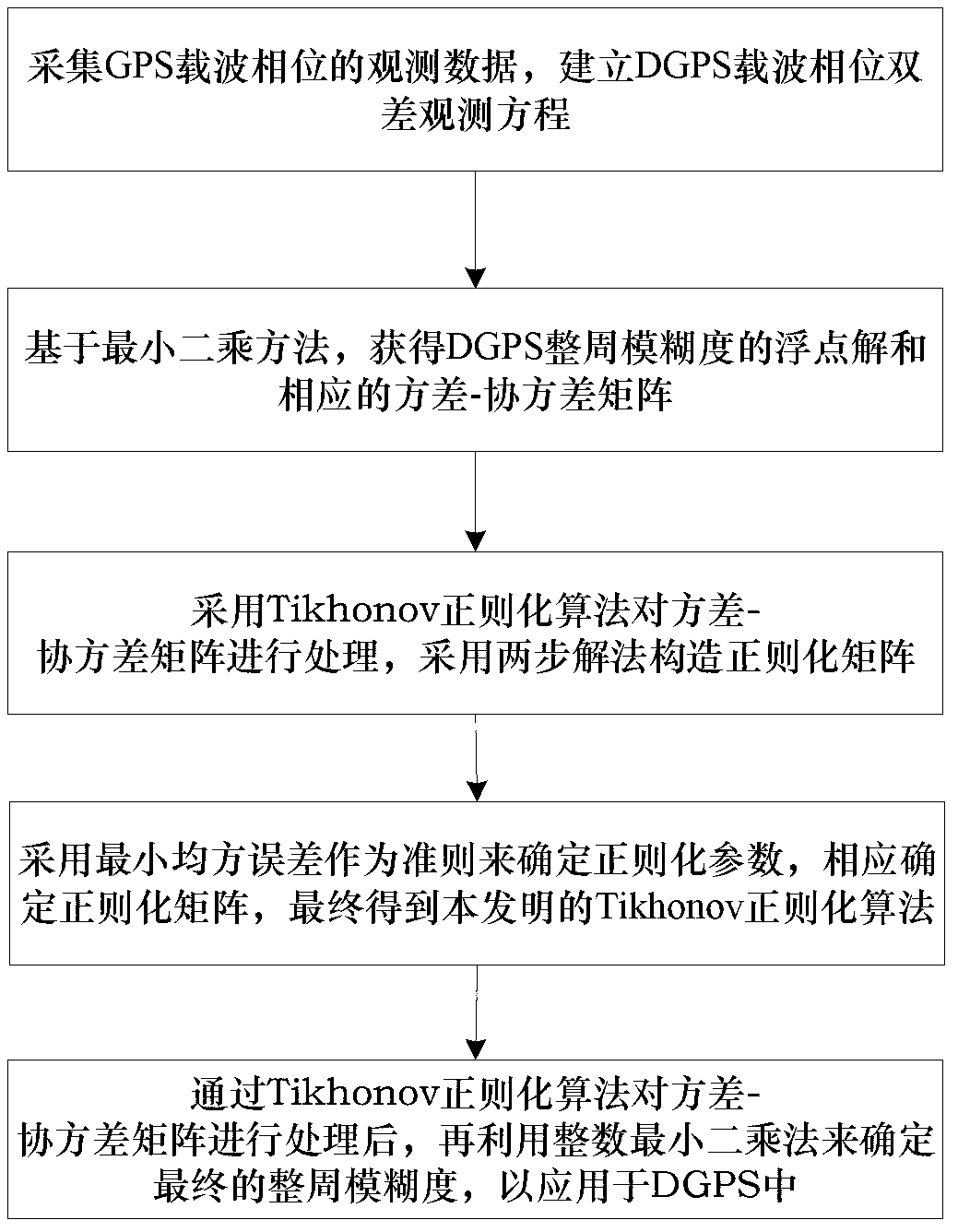

Method using improved regularization method to restrain difference global positioning system (DGPS) integer ambiguity ill-condition

InactiveCN103197335AFull week blur accuracyAchieve positioningSatellite radio beaconingDouble differenceObservation data

The invention discloses a method using an improved regularization method to restrain difference global positioning system (DGPS) integer ambiguity ill-condition. The method using the improved regularization method to restrain the DGPS integer ambiguity ill-condition comprises the steps of (1), collecting observation data of a global positioning system (GPS) carrier phase, building a DGPS carrier phase double-difference observation equation; (2) obtaining a floating point solution of DGPS integer ambiguity and a corresponding variance-covariance matrix based on a least square method according to the DGPS carrier phase double-difference observation equation; (3) and using a two-step solution to build a regularization matrix in a Tikhonov regularization algorithm, obtaining a corresponding regularization parameter according to a DFP quasi-newton method, processing the variance-covariance matrix by using the obtained Tikhonov regularization algorithm, restraining ill-condition of the DGPS integer ambiguity, and at last obtaining accurate integer ambiguity. According to the method using the improved regularization method to restrain the DGPS integer ambiguity ill-condition, the improved Tikhonov regularization algorithm is used for restraining the problem of the ill-condition in the DGPS integer ambiguity, the method using the improved regularization method to restrain the DGPS integer ambiguity is beneficial for obtaining the accurate integer ambiguity, and high-accuracy positioning and attitude measurement of DGPS can be achieved.

Owner:HARBIN ENG UNIV

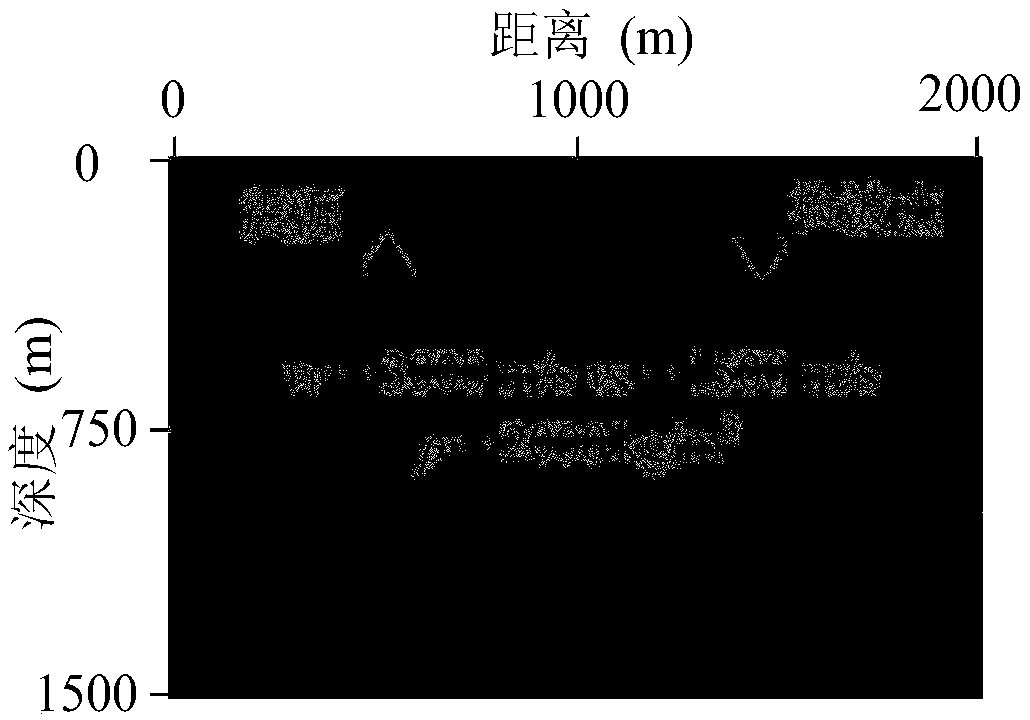

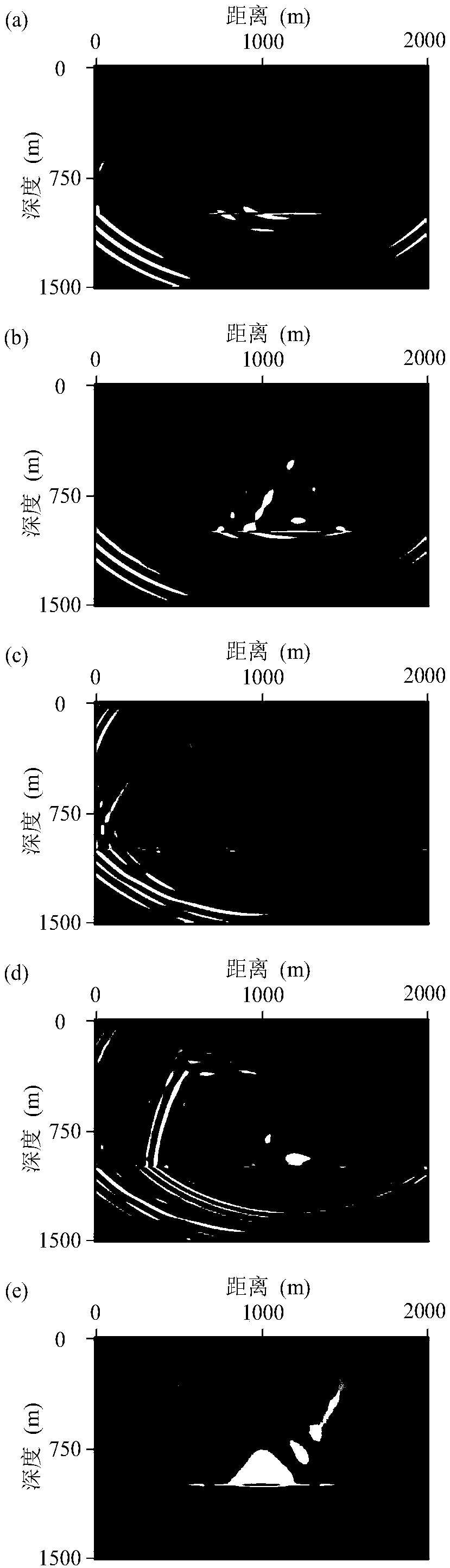

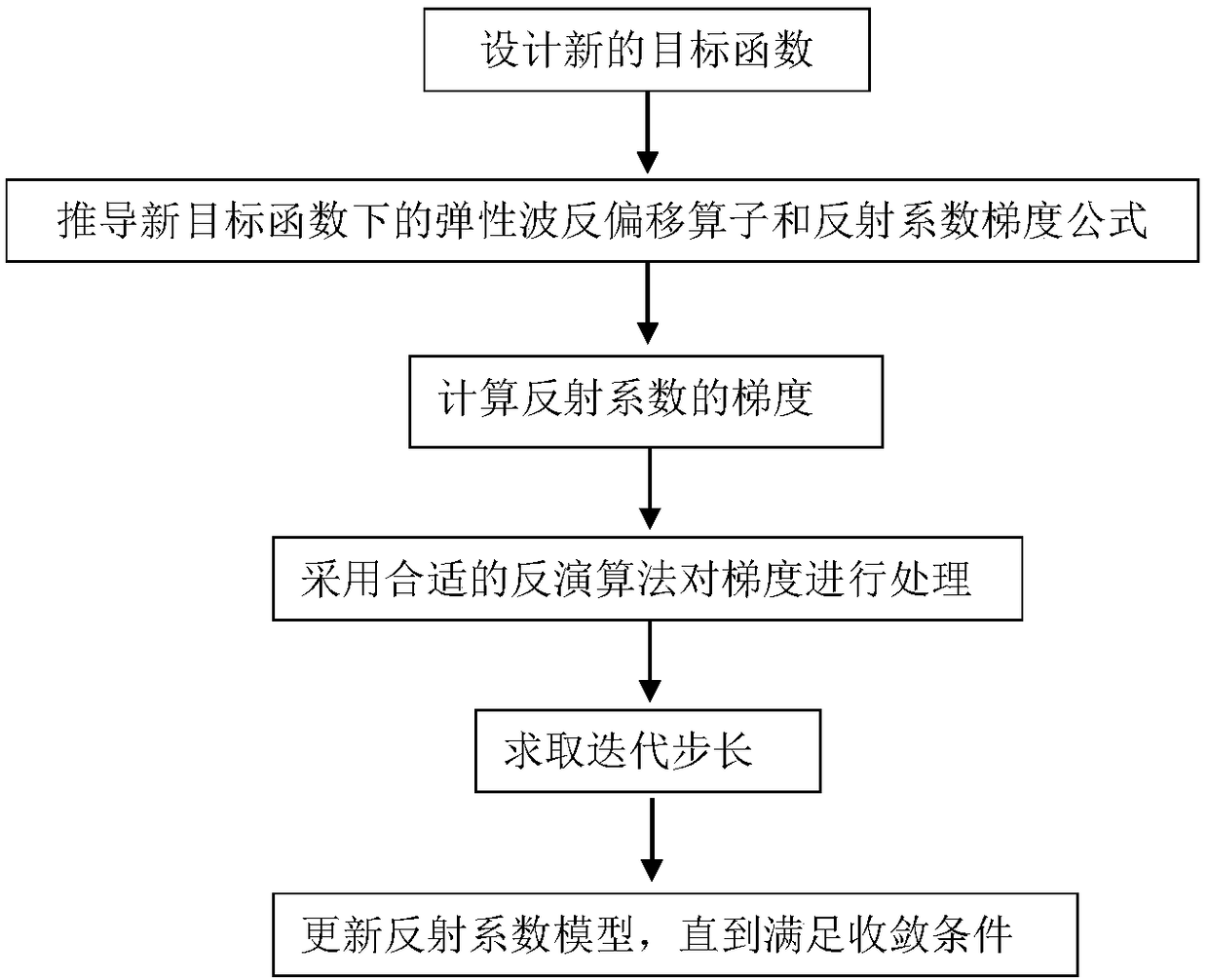

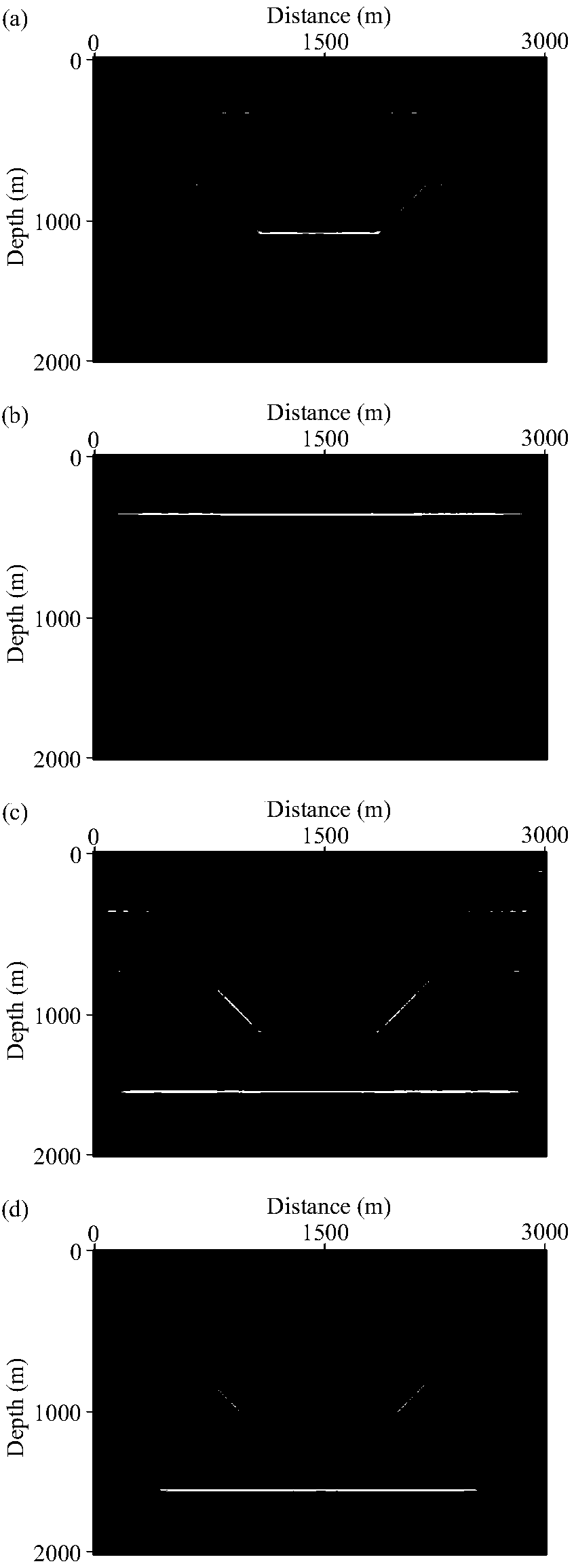

Elastic wave least squares reverse time migration method based on regularization constraints

ActiveCN108333628AImproving Imaging AccuracyImprove imaging resolutionSeismic signal processingReverse timeImage resolution

The invention discloses an elastic wave least squares reverse time migration method based on regularization constraints. The method includes the steps of designing a new objective function; deriving an elastic wave back-offset operator and a reflection coefficient gradient formula under the new objective function; calculating a gradient of a reflection coefficient; using a conjugate gradient method or a quasi-Newton inversion algorithm for processing the gradient; using a parabola fitting method for obtaining an iterative step size; updating a reflection coefficient model until convergence conditions are satisfied. The method has the advantage of adopting a new full variation regularization constraint strategy for increasing the imaging resolution and improving the stability.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

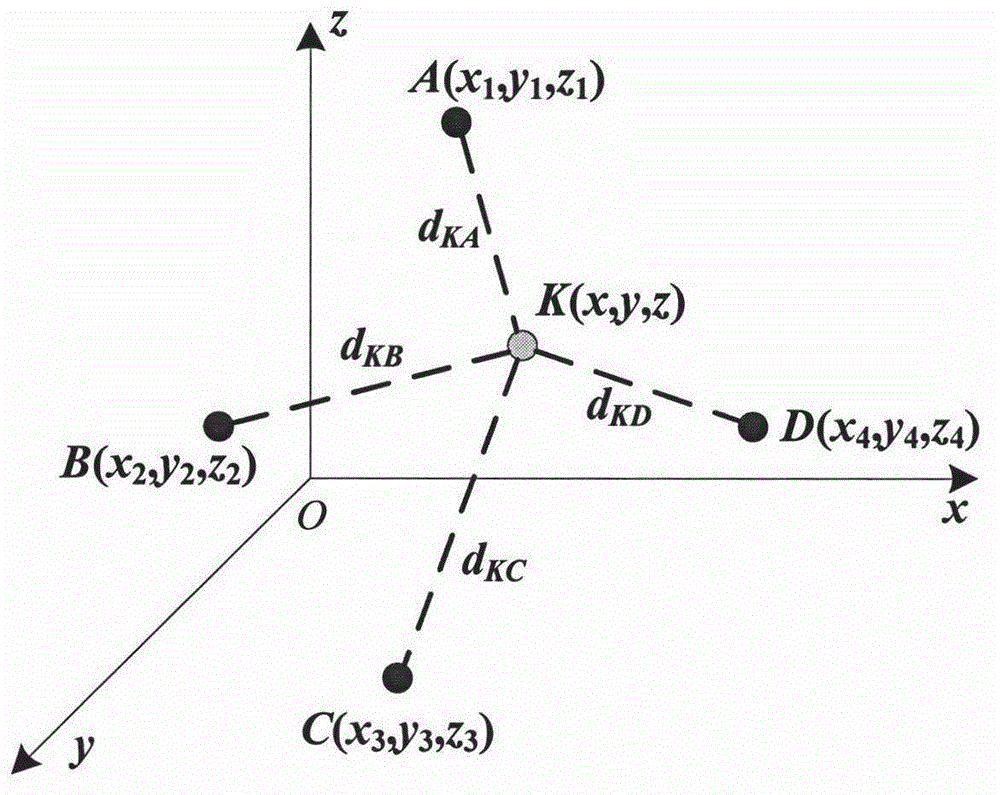

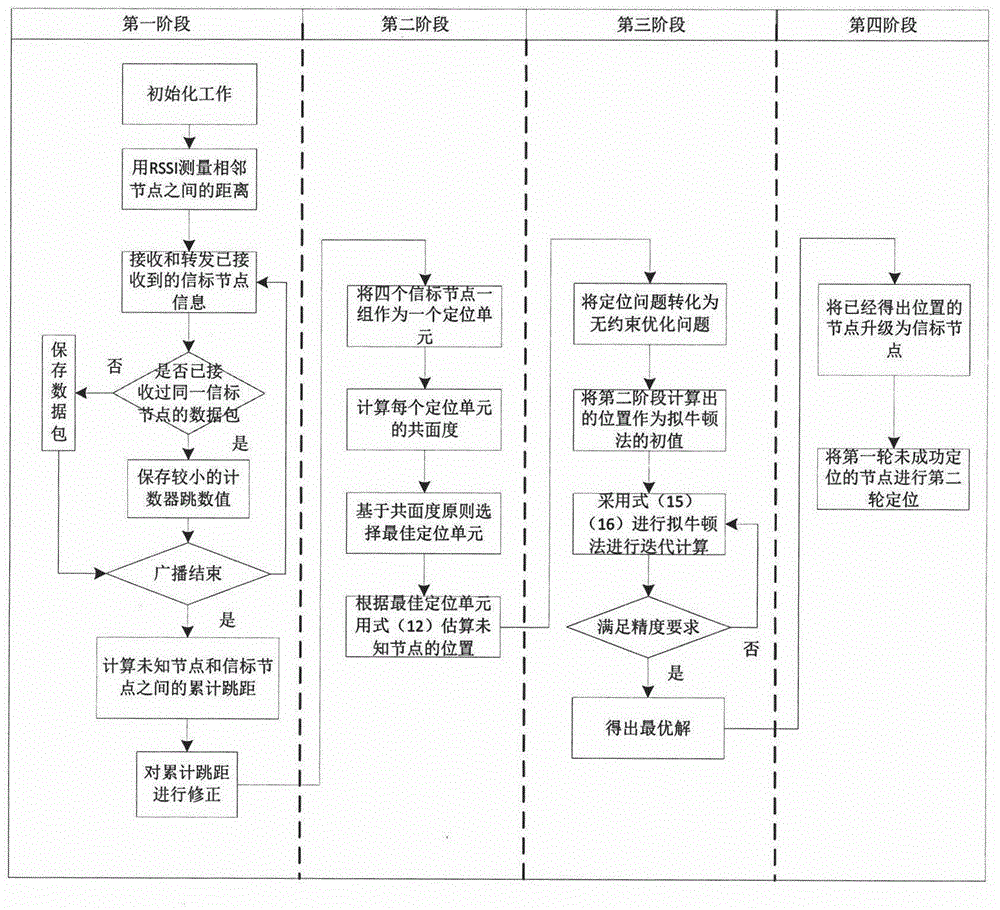

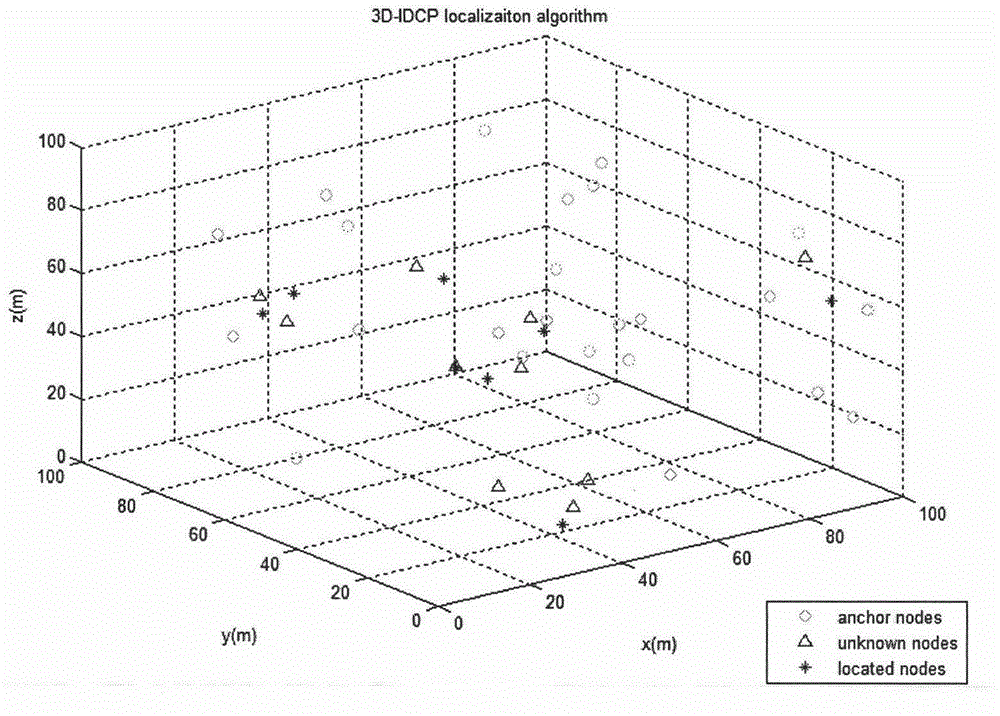

Skip distance correction WSN three-dimensional space target positioning method based on coplanarity

InactiveCN104968046AEliminate positioning errorsHigh precisionNetwork topologiesLocation information based serviceAlgorithmThree-dimensional space

The invention discloses a skip distance correction WSN three-dimensional space target positioning method based on coplanarity. The method comprises the following steps: first, the RSSI distance measurement technology is employed to measure a distance between adjacent nodes; second, beacon node information is received and transmitted through a distance vector exchange protocol, and minimum skip values and cumulative distance of all the nodes and a beacon node are obtained; third, a correction parameter is calculated, and the cumulative distance is corrected according the correction parameter; fourth, the coplanarity value of each positioning unit is calculated, and the best positioning unit is selected based on the coplanarity values; fifth, a four-face measuring method is employed to calculate a coordinate of an unknown node according to the selected best positioning unit; sixth, a quasi-Newton method is employed to optimize the coordinate of the unknown node; seven, the node positioned successfully is raised to a beacon node to participate in secondary positioning. The best positioning unit suitable for positioning is selected based on coplanarity values, the quasi-Newton method is employed to raise the positioning result precision, and positioning precision and the positioning coverage rate of three-dimensional space positioning can be raised.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

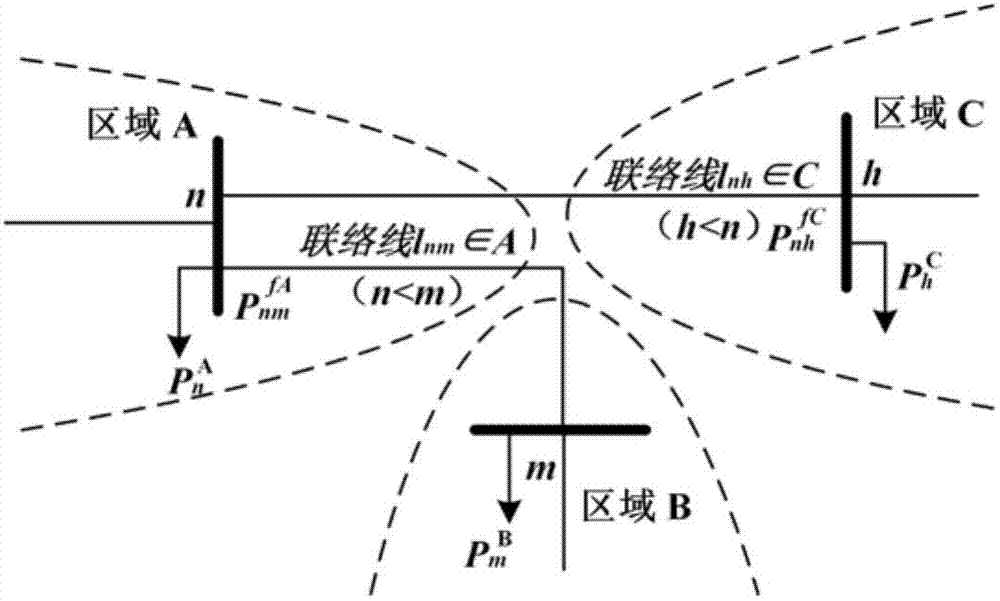

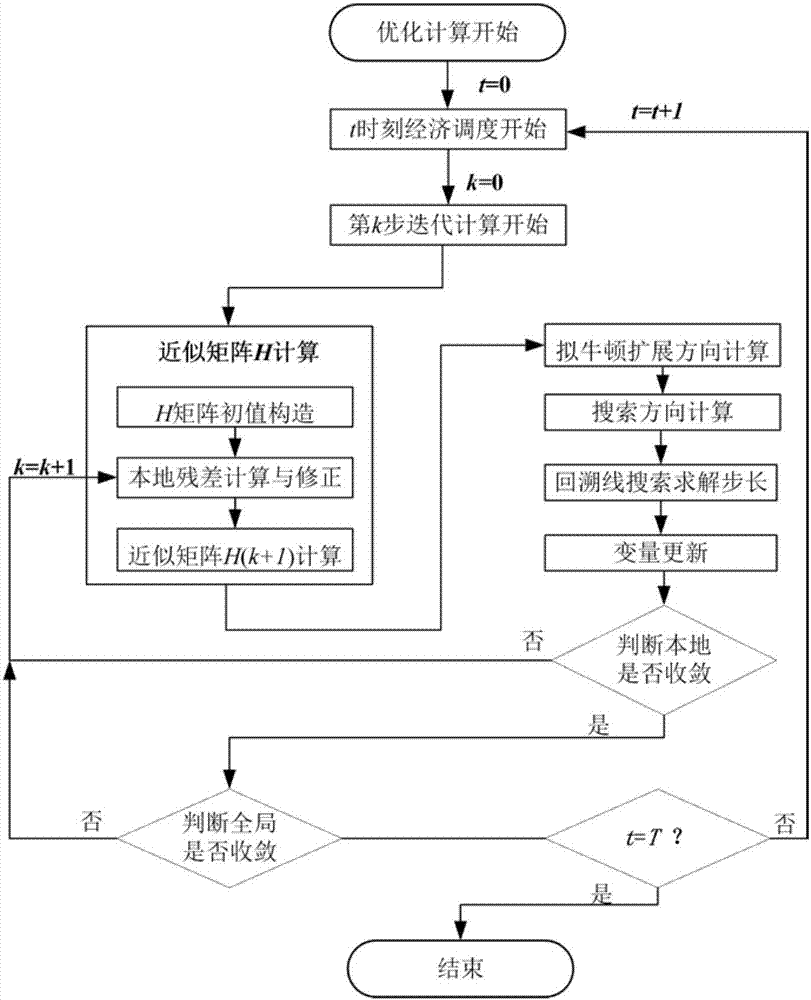

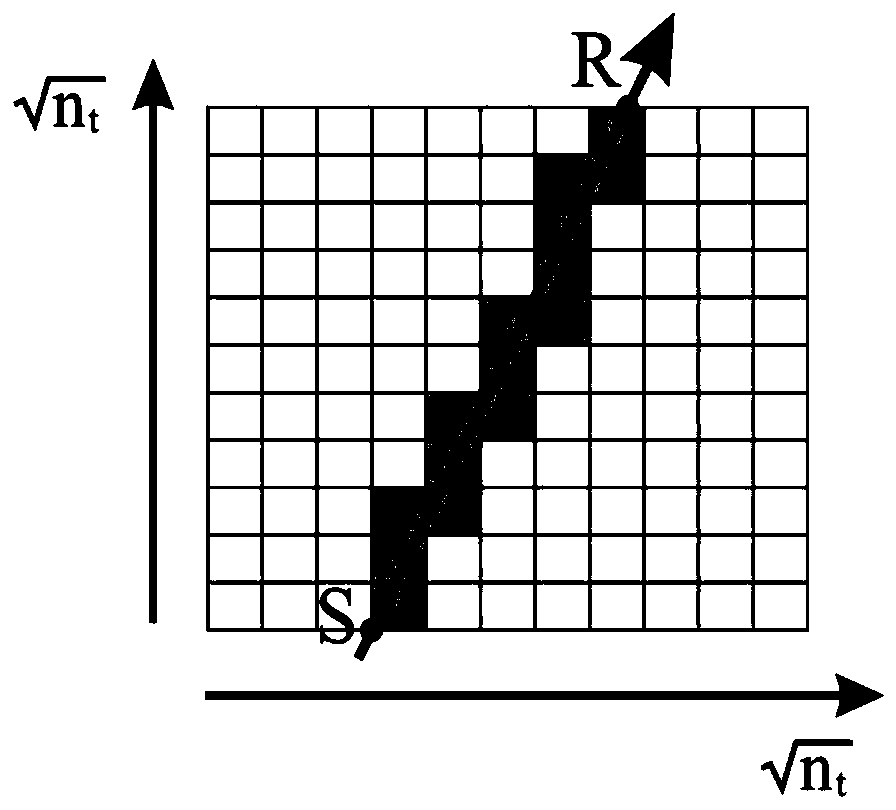

Multi-regional fully distributed active distribution network economic dispatching method

InactiveCN107482673AMaximize utilizationReduce light lossSingle network parallel feeding arrangementsPhotovoltaic energy generationElectric power systemTransmission loss

The invention relates to a multi-regional fully distributed active distribution network economic dispatching method and belongs to the field of electric power system operation and control technology, and the method comprises the steps: 1) establishing an active distribution network economic dispatching model for considering linearizing transmission losses and minimum light discarding cost; 2) realizing localization quasi-Newton matrix iteration initial value construction, localization quasi-Newton direction iterative computation and localization step size searching calculation for regions through neighbor boundary node communication; 3) judging whether global convergence is achieved through the neighbor communication after regional convergence. According to the invention, the method aims at operating characteristics of an active distribution network, point-to-point communication technology are fully utilized, on the basis of fully distributed quasi-Newton method, the method complete active distribution network economic dispatching multi-regional fully distributed superlinear convergence computation without a coordination center, the reliability is improved, privacy of the regions is protected, and plug-and-play is realized.

Owner:TSINGHUA BERKELEY SHENZHEN INST

Non-rigid multimode medical image precise registering method

ActiveCN103345741ATake full advantage of representational capabilitiesBest deformation parameterImage analysisGrid deformationReference image

The invention discloses a non-rigid multimode medical image precise registering method. The non-rigid multimode medical image precise registering method includes the following steps that normalization processing is performed on a reference image and a floating image. A pulse sending cortex model is used for processing so as to obtain two ignition mapping images. A Sobel operator is used for respectively abstracting edge features of the two ignition mapping images to obtain corresponding gradient images. A sum of squareddifferences of the two gradient images is calculated out. Finally, based on a free grid deformation model and the sum of squareddifferences a target function is determined. A quasi-Newton method is used for performing iterative optimization on the target function to obtain optimal deformation parameters. According to the non-rigid multimode medical image precise registering method, the pulse sending cortex model and the sum of squareddifferences are used for performing non-rigid multimode medical image registering and registering precision is greatly improved.

Owner:维视医学影像有限公司

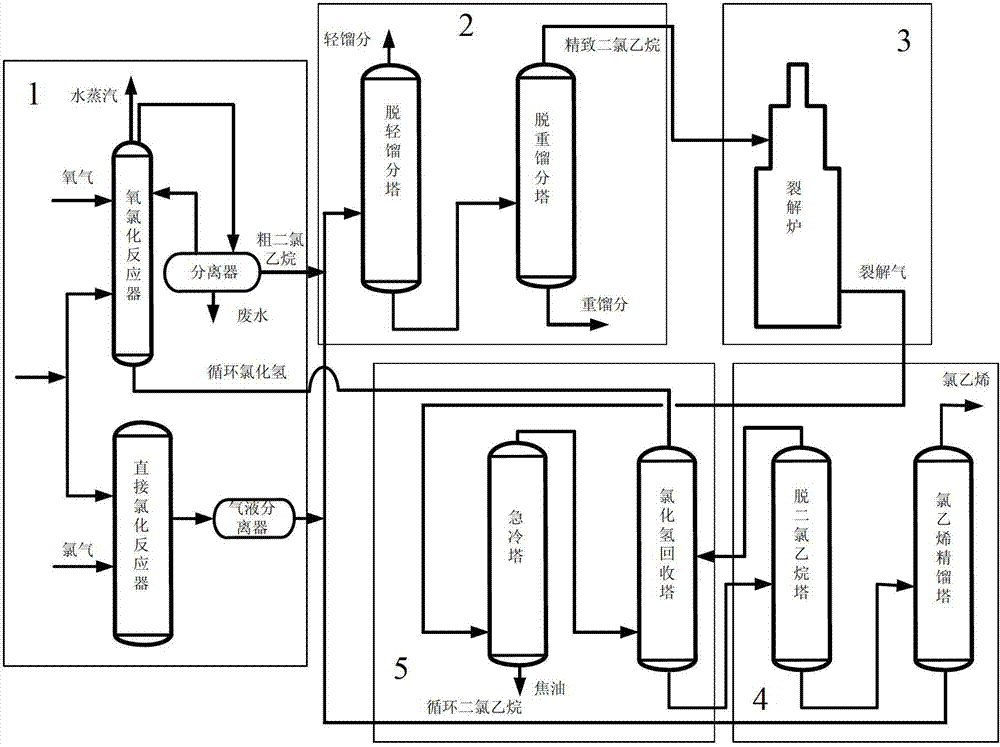

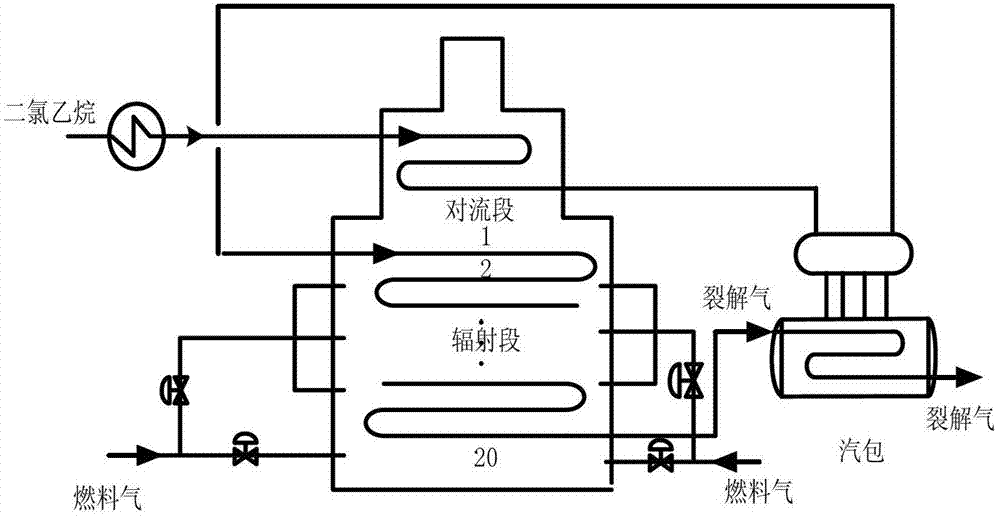

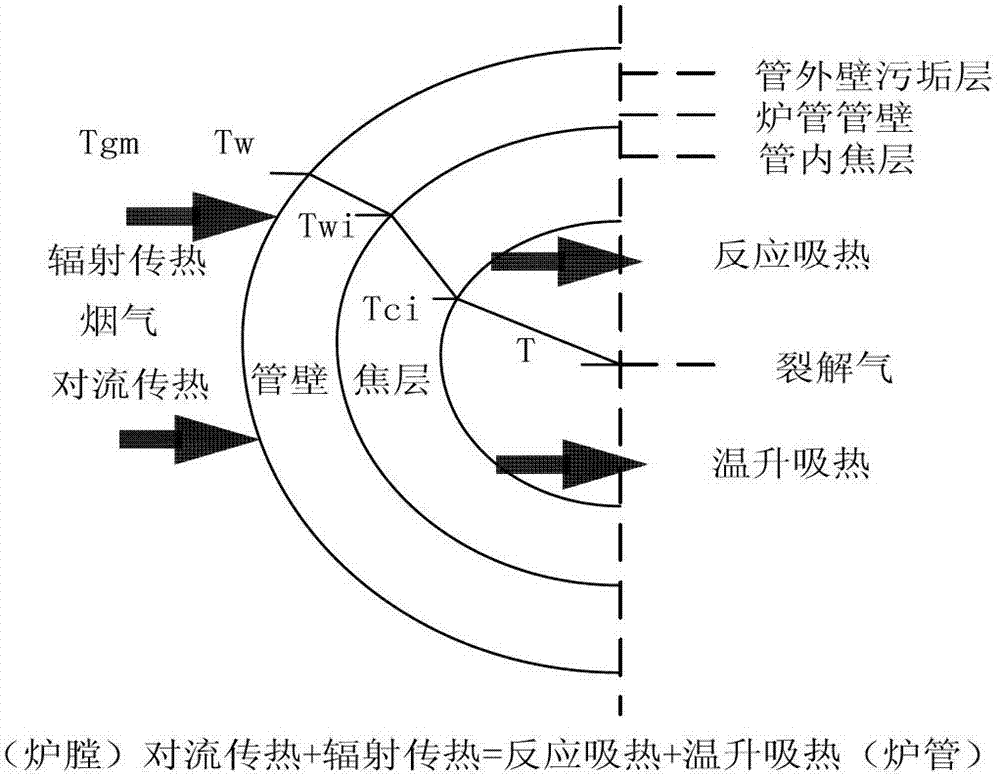

Industrial unit dichloroethane cracking furnace coupled modeling method and application

ActiveCN102779203APreparation by hydrogen halide split-offSpecial data processing applicationsAbsorption capacityReal-time data

The invention relates to an industrial unit dichloroethane cracking furnace coupled modeling method and application. In the method, during modeling, a dichloroethane cracking furnace is divided into a hearth model and a furnace tube model, a one-dimensional partition method in combination with method is used for the hearth, the smoke temperature distribution condition of the hearth is solved by a heat balance equation, for the furnace tube model, the furnace tube is partitioned according to the amount of straight tube sections of a radiant section, and the reaction and the heat absorption capacity in the tube are calculated section by section. The hearth model and the furnace tube model are mutually iterated through a quasi-newton method according to the calculated smoke temperature and heat transfer rate information, until meeting the convergence precision and the model precision. The model is based on the dynamical model and the energy conservation relation, and is corrected by real-time data so as to further measure the relevant parameters of the cracking furnace in a soft sensing manner. The accurate model is the basis of optimization, provides reliable model basis for optimization of field important economic indicators, such as the outlet temperature of the furnace tube of the cracking furnace, the dichloroethane cracking conversion rate, the selectivity, the unit consumption and so on, and realizes real-time soft sensing of relevant parameters.

Owner:EAST CHINA UNIV OF SCI & TECH

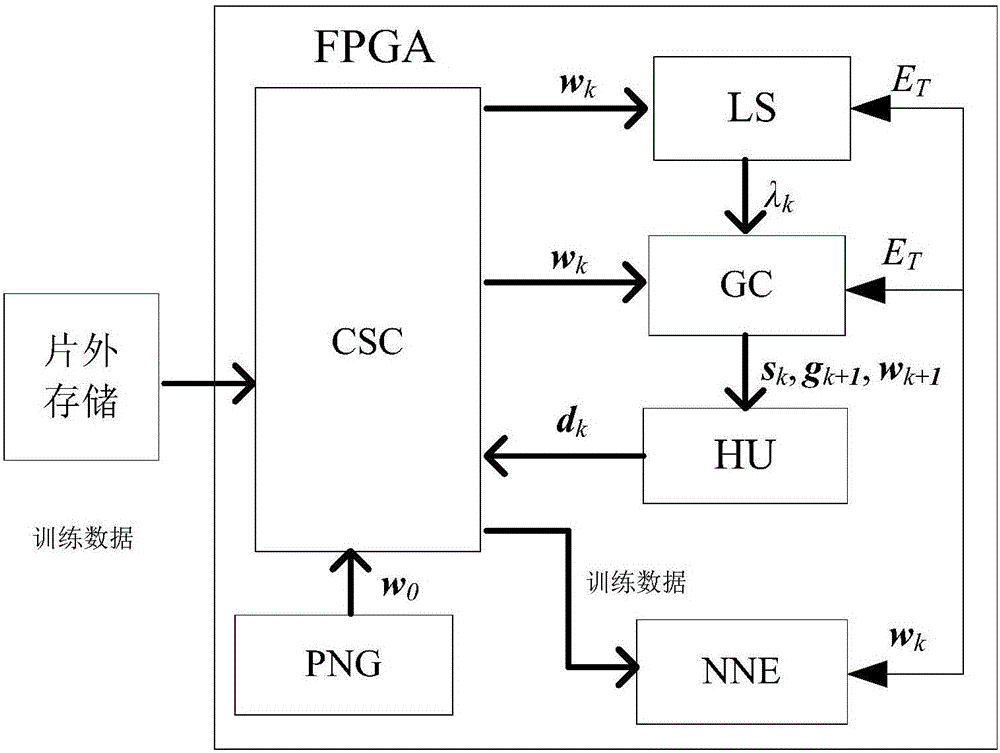

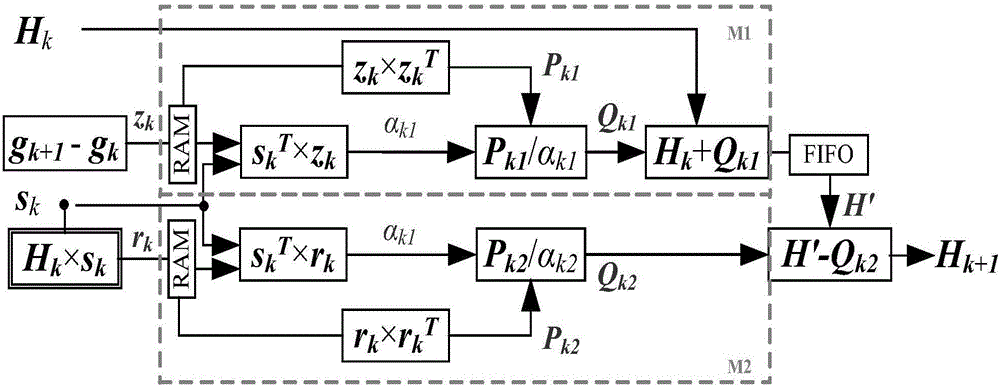

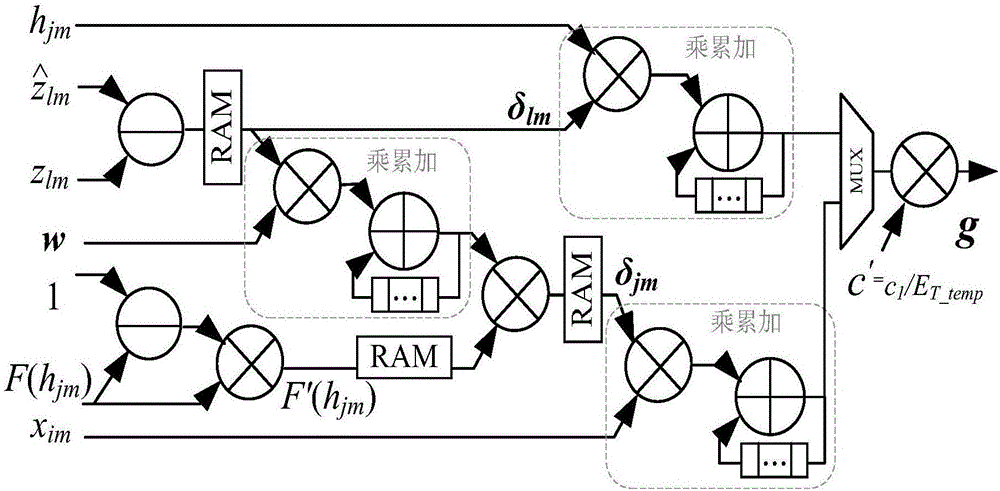

FPGA system and implementation method based on on-line training neural network of quasi-newton method

InactiveCN106528357AMeet the real-time needs of online trainingScalableDetecting faulty hardware using neural networksShift registerHardware structure

The invention discloses a FPGA system and implementation method based on an on-line training neural network of the quasi-newton method. The FPGA system comprises modules of LS, GC, HU, NNE, CSC and PNG. The implementation method includes 1 analyzing c++ codes of the quasi-newton method, dividing the algorithm into three calculation modules, and converting each calculation module into a hardware block by editing Verilog; 2 determining the hardware structure of a neural network evaluation module NNE by editing Verilog according to the topological structure, training method and excitation function of the neural network; 3 generating a module PNG by realizing the random number on the basis of a 32-bit linear shift register; 4 adopting a FPGA on-chip memory as a buffer to link the five hardware modules, storing the middle calculation results, and determining the operation order of the five modules and implementing data delivery between memory and corresponded modules in a manner of a finite state machine; 5 carrying out performance test through hardware design. The speed of neural network training can be increased through the FPGA, and the real-time capability requirements of neural network on-line training can be met.

Owner:TIANJIN UNIV

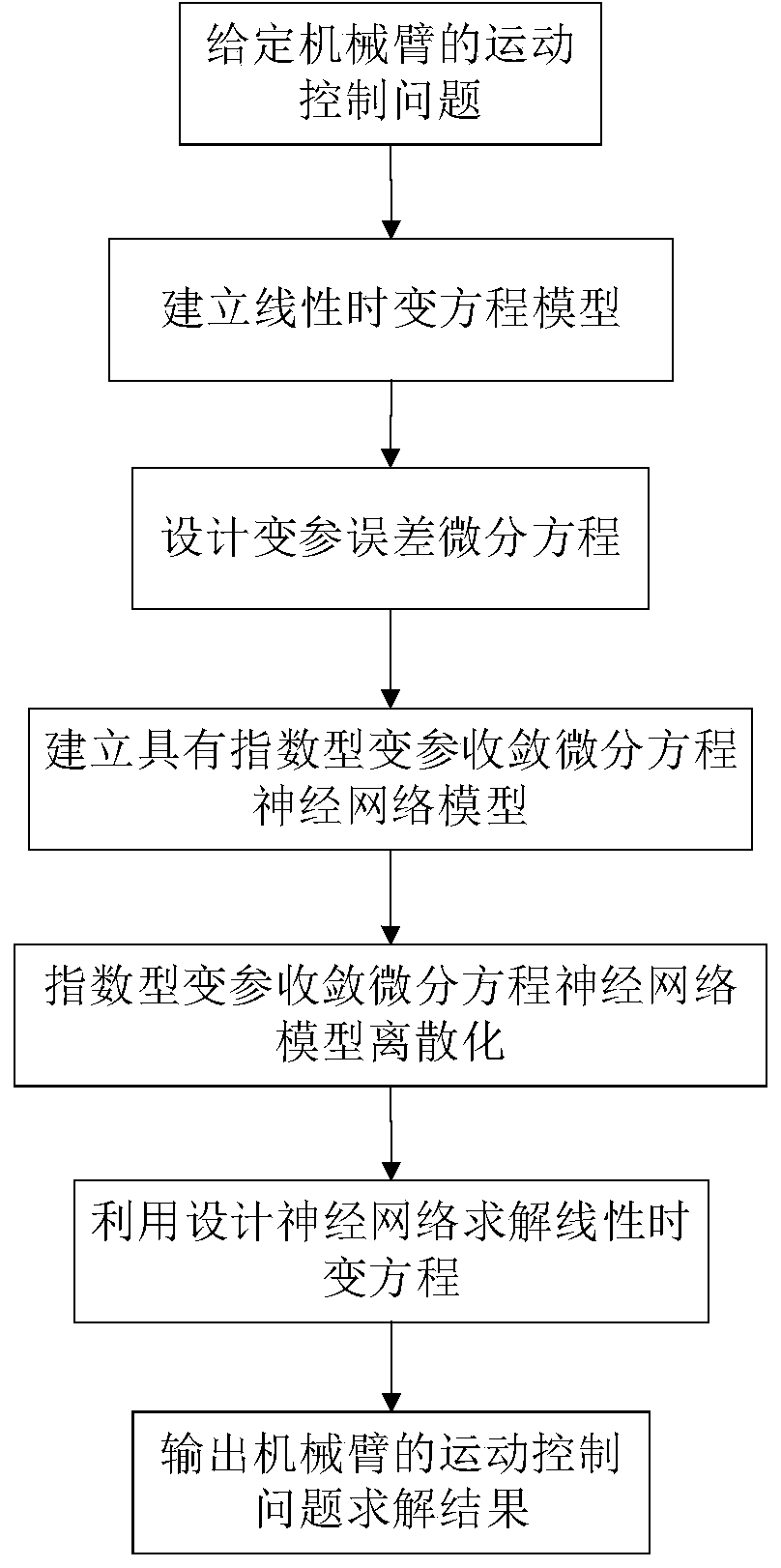

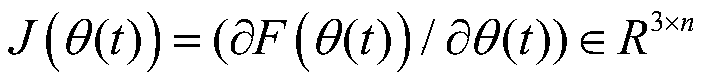

Method for solving motion control of redundant mechanical arm

ActiveCN111037550ASolve the time-varying problem that cannot be solved by online solution of mechanical arm motionTo achieve the technical effect of motion controlProgramme-controlled manipulatorAlgorithmControl engineering

The invention discloses a method for solving motion control of a redundant mechanical arm. The method comprises the following steps of modeling a motion control problem of the mechanical arm accordingto a given tail end track of the mechanical arm, and converting the motion control problem into a linear time-varying equation; converting a motion control solving problem of the mechanical arm intoa solving problem of the linear time-varying equation, designing an error differential equation with exponential type variable parameters for the linear time-varying equation, and establishing an exponential type variable parameter convergence differential neural network model; dispersing an exponential type variable parameter convergence differential neural network by adopting an Euler forward differential formula and a BFGS quasi-Newton method; solving the linear time-varying equation by using the exponential type discrete variable parameter convergence neural network; and transmitting a result obtained by solving to a given linear time-varying system, and solving the motion control problem of the given mechanical arm. According to the method, the motion control problem of the given mechanical arm can be quickly solved with high precision, and a discretization result can be output after discretization, so that the method is suitable for controlling a discrete input system by a digital circuit.

Owner:SOUTH CHINA UNIV OF TECH

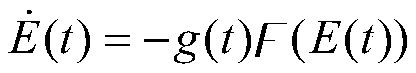

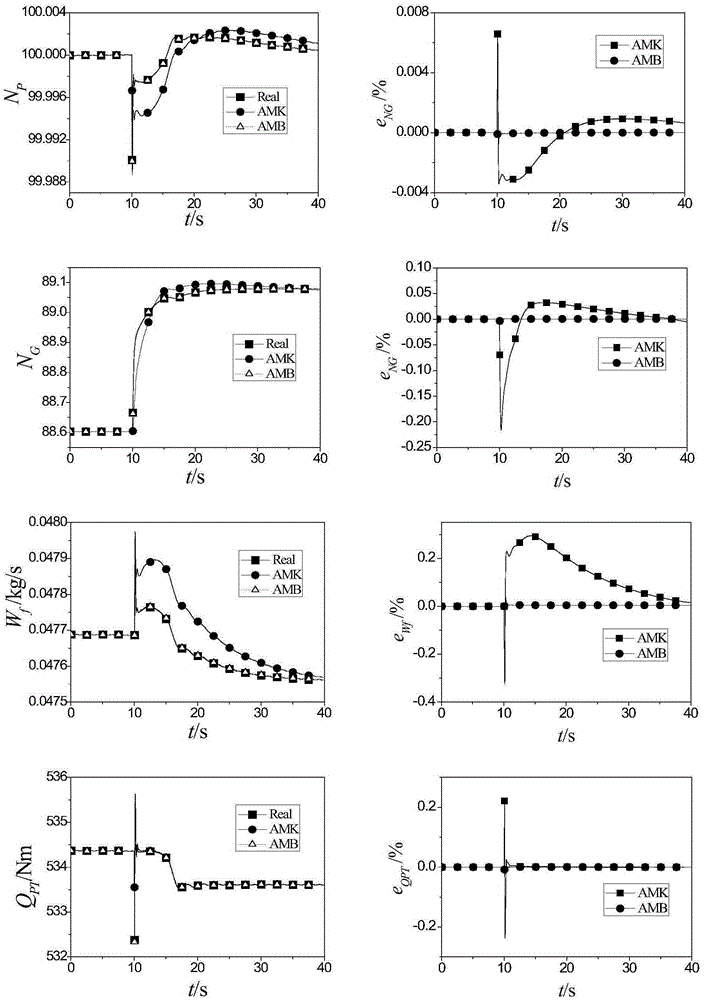

Turboshaft engine self-adaptive model building method based on modified Broyden algorithm to solve equation set

InactiveCN105404750AThere is no problem of poor adaptabilityImprove adaptabilitySpecial data processing applicationsNonlinear systems of equationsSelf adaptive

The present invention discloses a turboshaft engine self-adaptive model building method based on a modified Broyden algorithm to solve an equation set. The method comprises: matching a self-adaptive model with a real engine by forming and solving the equation set. A non-linear equation set is established according to a principle in which a model outputs a tracked real engine output and in combination with a coacting equation between engine parts, and the equation set is solved by using a modified Broyden algorithm, to acquire a part performance degradation parameter and a turboshaft engine part level model guess value. The modified Broyden algorithm is based on a Broyden quasi-newton method and is combined with a computation divergence determination and correction mechanism, so that computation accuracy and real-time performance are improved. The performance degradation parameter acquired by solving the equation set is introduced into a turboshaft engine part level model as an adjustable parameter, so that the model has a self-adaptive capability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

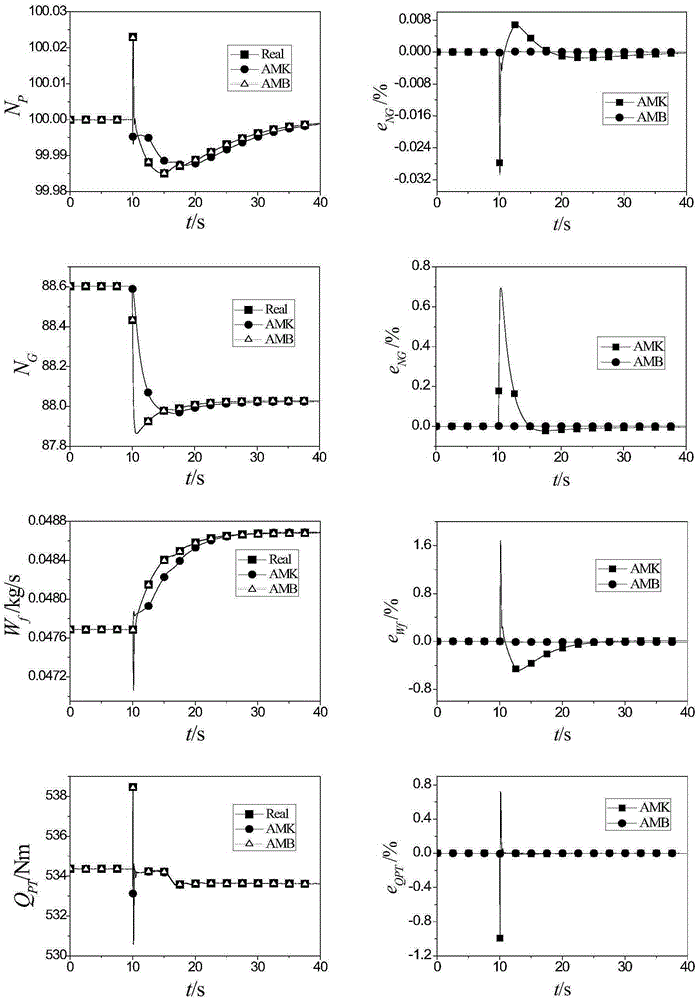

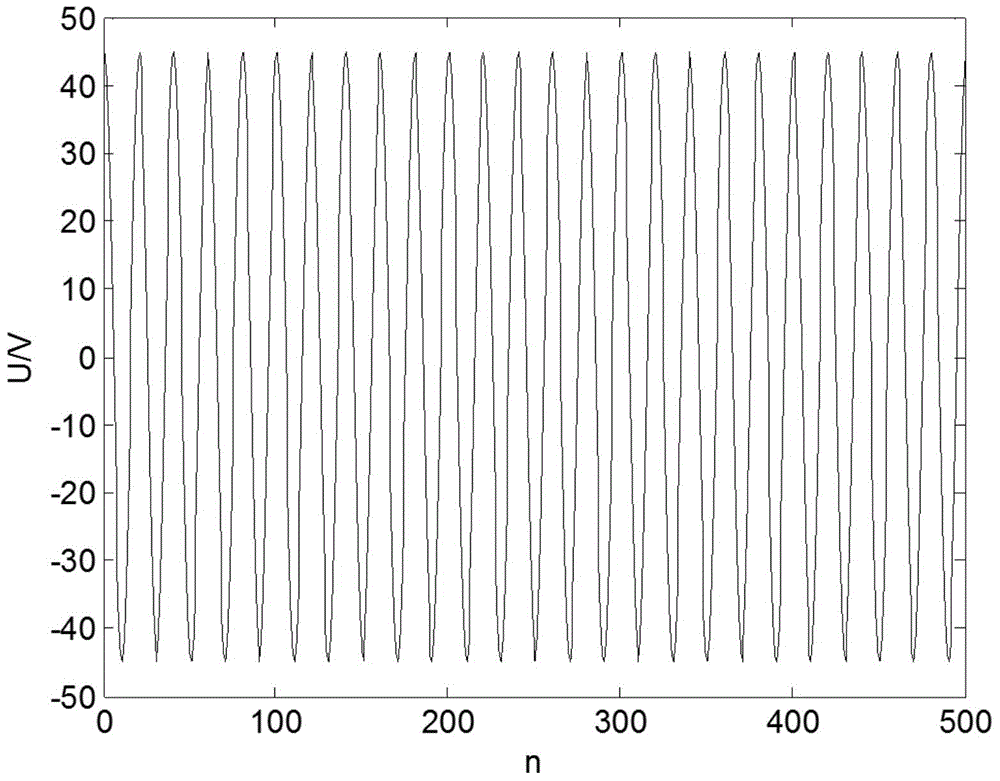

Harmonic current estimation method based on improved FastICA algorithm

InactiveCN104979829AAccurate estimateHigh precisionSpecial data processing applicationsHarmonic reduction arrangementEstimation methodsPower grid

The present invention discloses a harmonic current estimation method based on an improved FastICA algorithm. The harmonic current estimation method is characterized in that a quasi-Newton method is adopted to replace a Newton method as an optimization method of FastICA. The present invention has the beneficial effects that (1) harmonic currents in a power grid can be accurately estimated in the condition of unknown harmonic impedance; (2) the problems that a harmonic measuring device is difficultly obtained by the actual harmonic impedance of a system, and the cost is great are overcome; and (3) compared to the original method, the harmonic current estimation method is capable of improving the accuracy of the algorithm and better solving the problem that the harmonic impedance is difficult to determine.

Owner:HOHAI UNIV

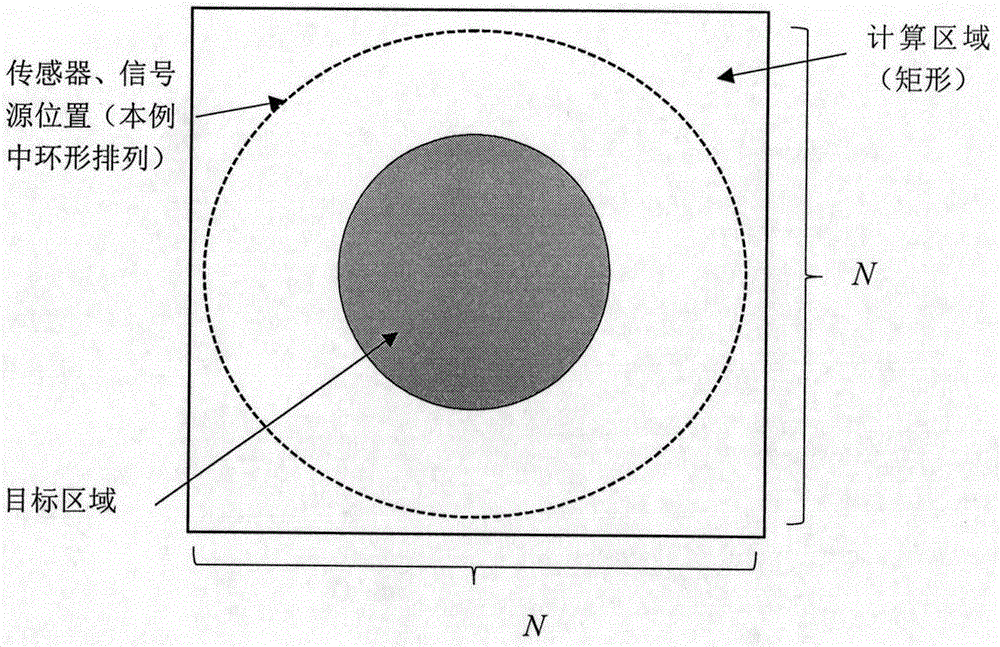

Ultrasound CT image reconstruction method and system based on ray theory

ActiveCN110051387AReduce the impact of systematic errorsReduce the impact of errorsUltrasonic/sonic/infrasonic diagnosticsReconstruction from projectionReconstruction methodAcoustic wave

The invention belongs to the technical field of functional imaging, and discloses an ultrasound CT image reconstruction method and system based on a ray theory. The method comprises an ultrasound CT sound velocity reconstruction method and an ultrasound CT attenuation coefficient reconstruction method based on the ray theory. The ultrasound CT sound velocity reconstruction method based on the raytheory includes: (1) extraction of the difference in transit time; (2) calculation of a ray path of sound wave from a transmitting element to a receiving element; (3) solving of an inverse problem: using the quasi-Newton method to solve the path-slowness-time equation to obtain the velocity reconstruction value vector of an object to be tested. By means of improvement of the overall flow of the method, in particular the optimization of the ray theory, the fast stable ultrasonic CT sound velocity reconstruction and ultrasonic CT attenuation coefficient reconstruction can be achieved by utilizing the specific ray calculation treatment mode, and the ultrasound CT image reconstruction based on the ray theory can be further achieved.

Owner:WUHAN WESEE MEDICAL IMAGING CO LTD

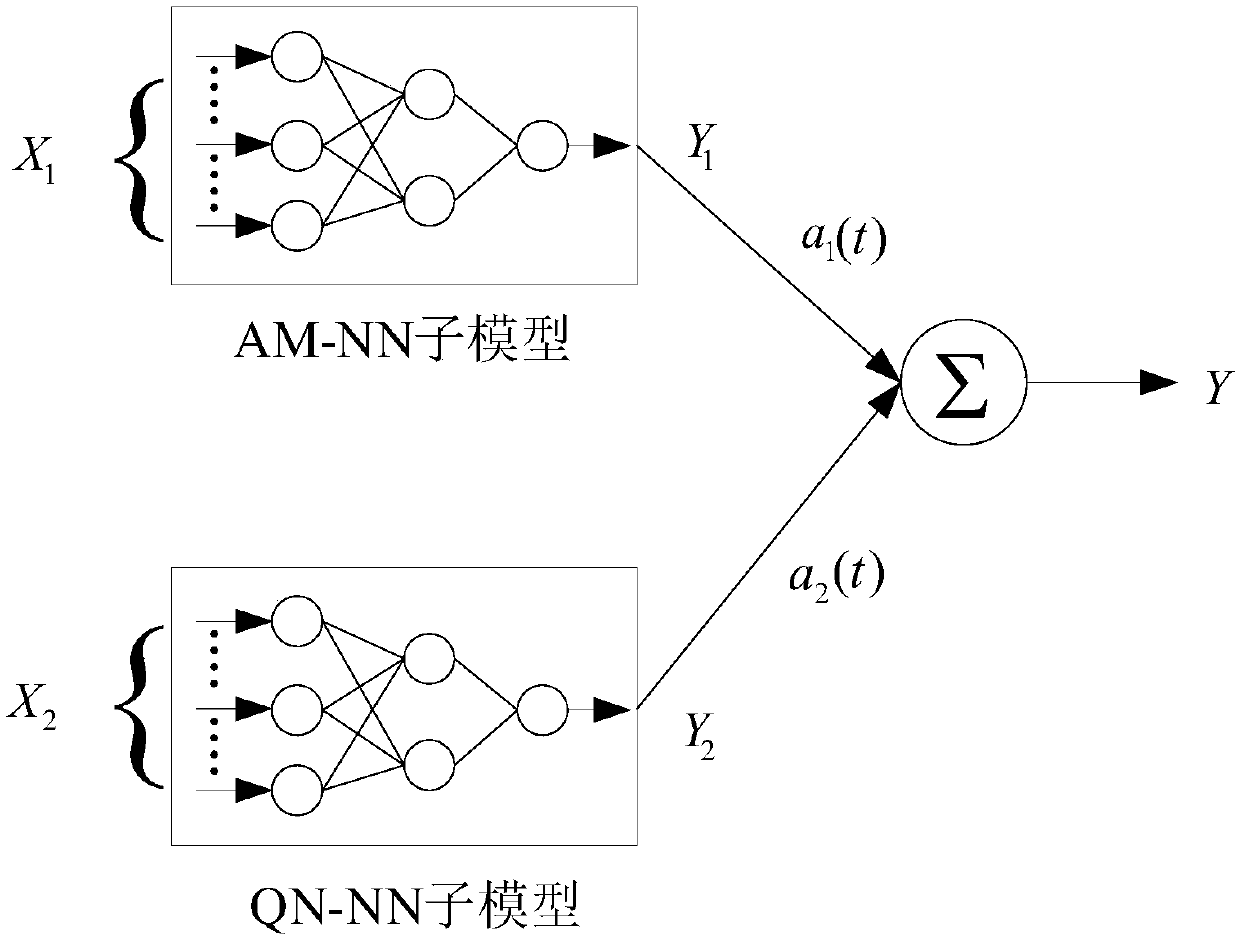

Electric power system short period load prediction method based on combined neural network

The invention belongs to the power system short-term load prediction technology field and discloses an electric power system short period load prediction method based on the combined neural network. The method comprises steps that (1), historical power grid load and meteorological data are collected, and a database is built for backup; (2) abnormal data acquired in the step (1) is removed, and normalization processing of the residual data is carried out; (3), a model structure having feedforward and feedback functions is determined; (4), the historical data is utilized to train a prediction model, and model parameters and weights are determined; and (5), the prediction model is utilized for actual load prediction to acquire a prediction load value. The method is advantaged in that the combined neural network is composed of an AM-NN sub model based on the additional momentum method and a QN-NN sub model based on the Quasi-Newton method, the two models are fused through a time-varying comprehensive weight coefficient, meteorological factor data is introduced to the model, the rolling optimization strategy is employed, the model is made to have relatively good generalization and convergence property, and actual scheduling prediction requirements can be more precisely satisfied.

Owner:ZAOZHUANG POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

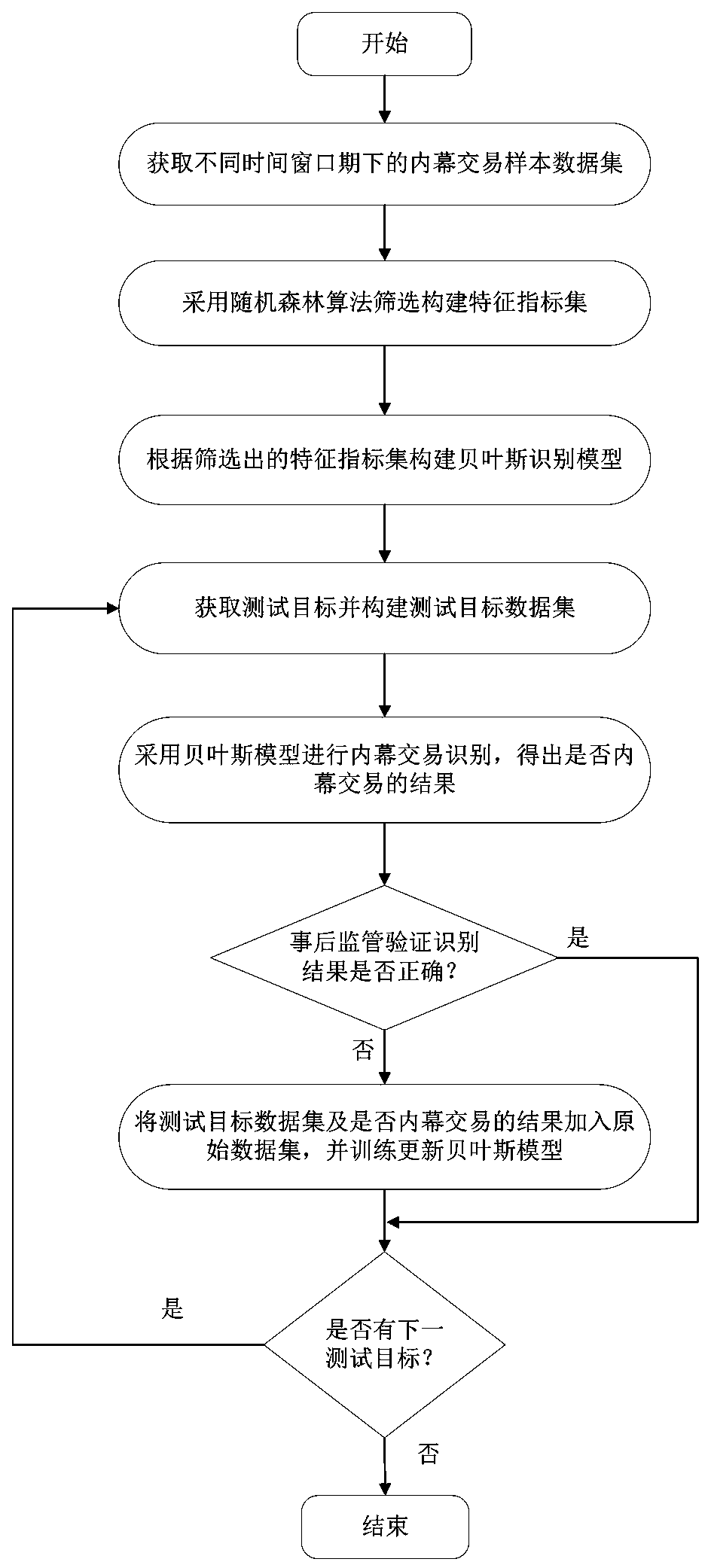

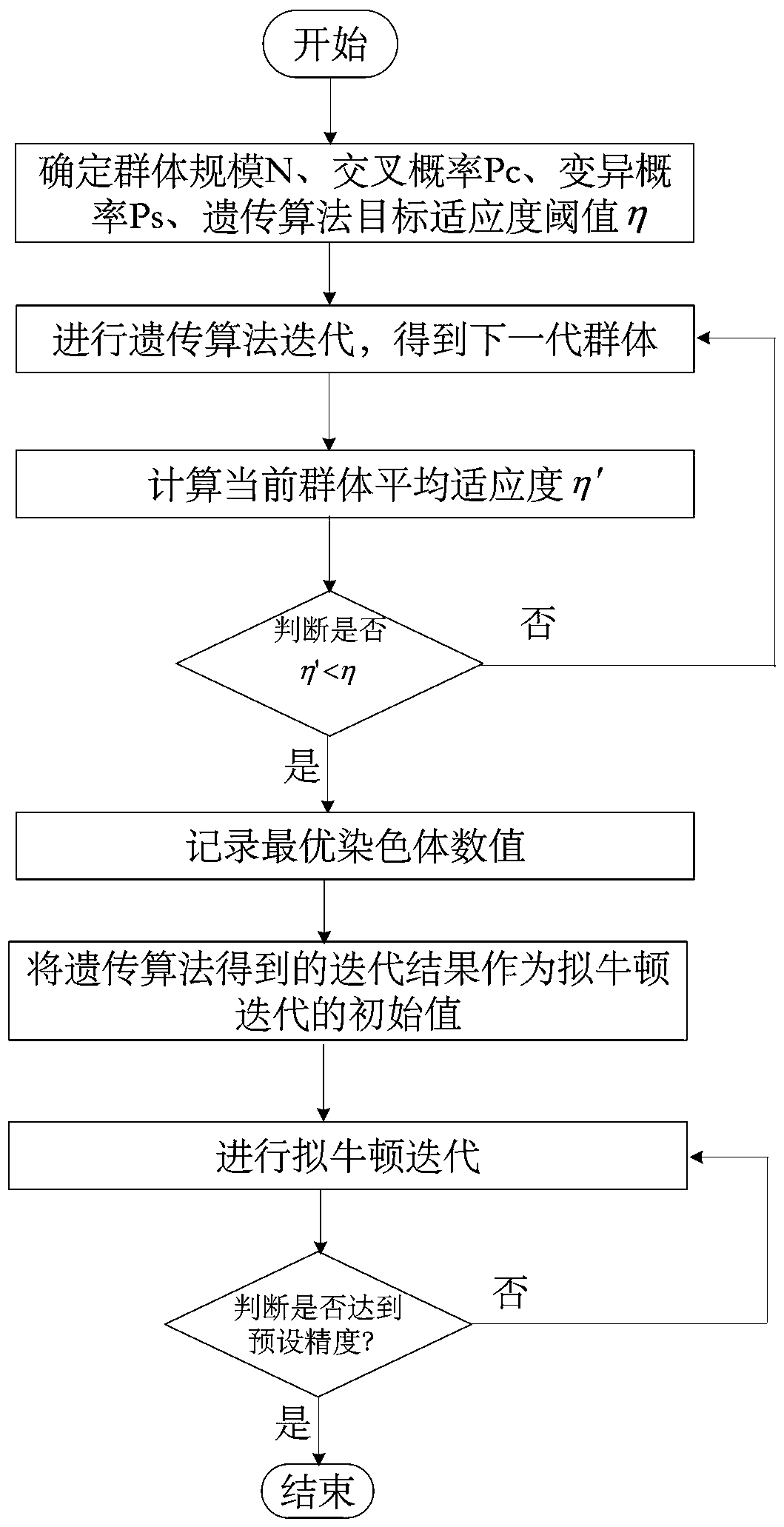

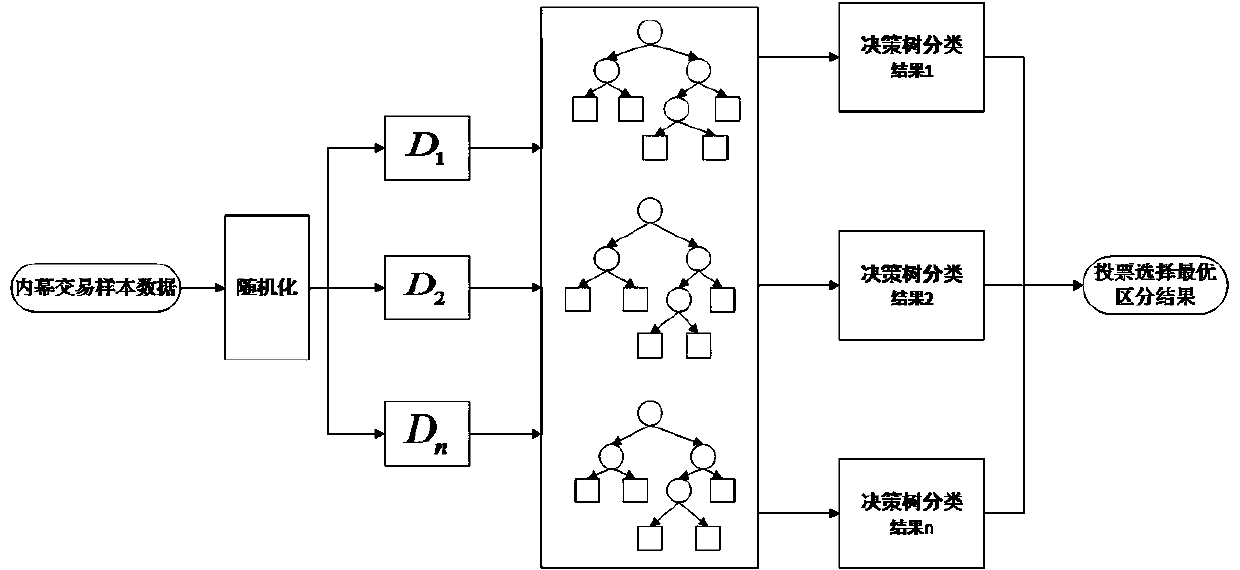

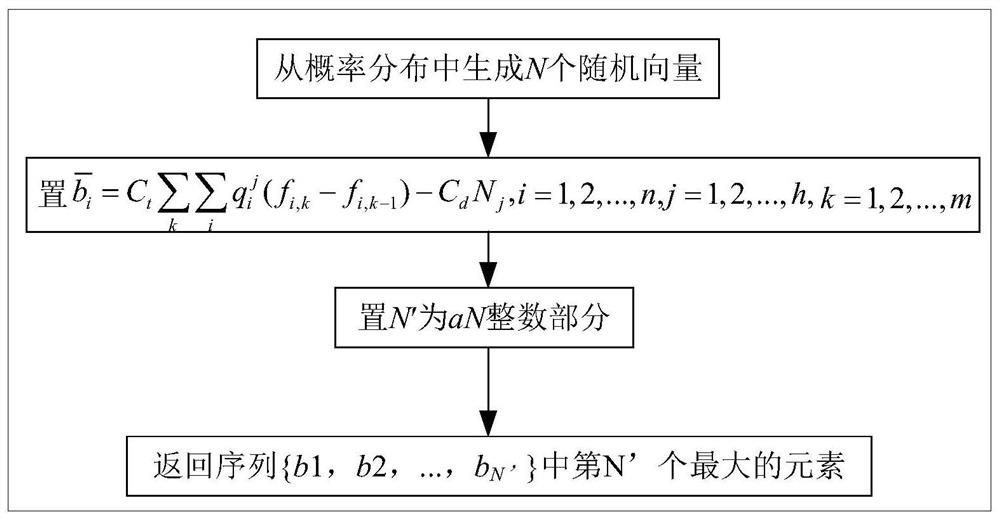

Intranet transaction identification method based on random forest and naive Bayes model

The invention discloses an intranet transaction identification method based on a random forest and a naive Bayes model. The method comprises the following steps: acquiring an internal screen transaction sample data set under different time window periods, screening and constructing a characteristic index set by adopting a random forest model, constructing a Bayesian identification model of the internal screen transaction according to the screened characteristic index set, and performing internal screen transaction identification by adopting the Bayesian identification model to obtain a resultof whether the internal screen transaction exists or not; and after the event, supervising and verifying whether the internal transaction recognition result is correct, and training and updating the Bayesian recognition model according to the recognition result. According to the invention, the stock intranet transaction identification model is established, so that whether the test target is subjected to intranet transaction or not is accurately identified; a quasi-Newton method and a genetic algorithm are combined, so that parameters of the random forest model are quickly optimized to an optimal solution with high precision, and the solution of the optimal solution has small dependence on an initial value; the method is easy to implement and stable in performance, and robustness and accuracy can be further improved along with increase of sample data.

Owner:CHINA THREE GORGES UNIV

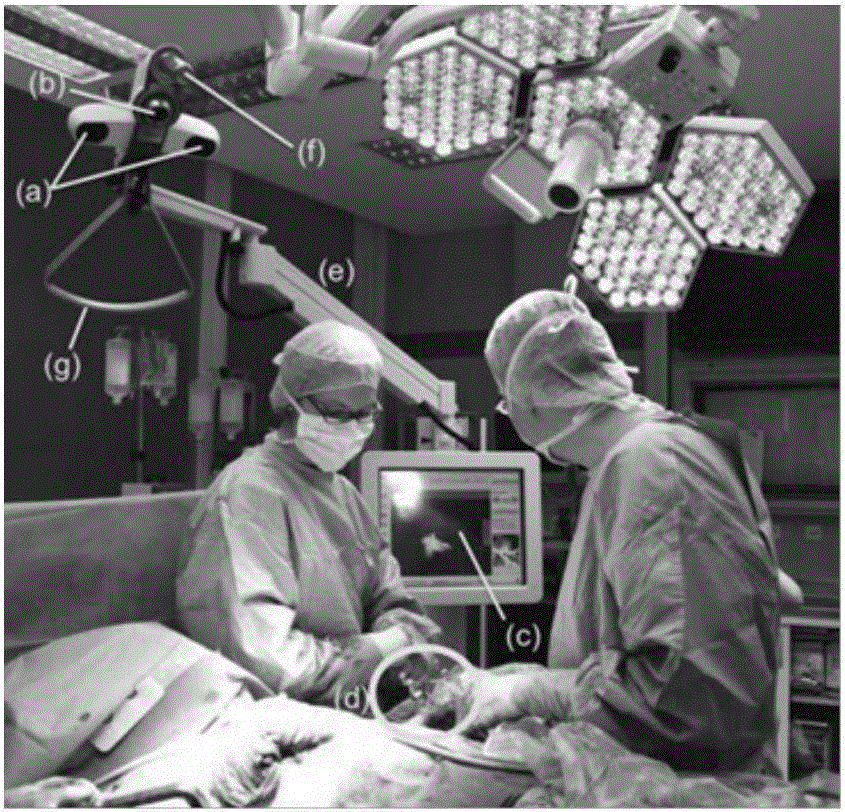

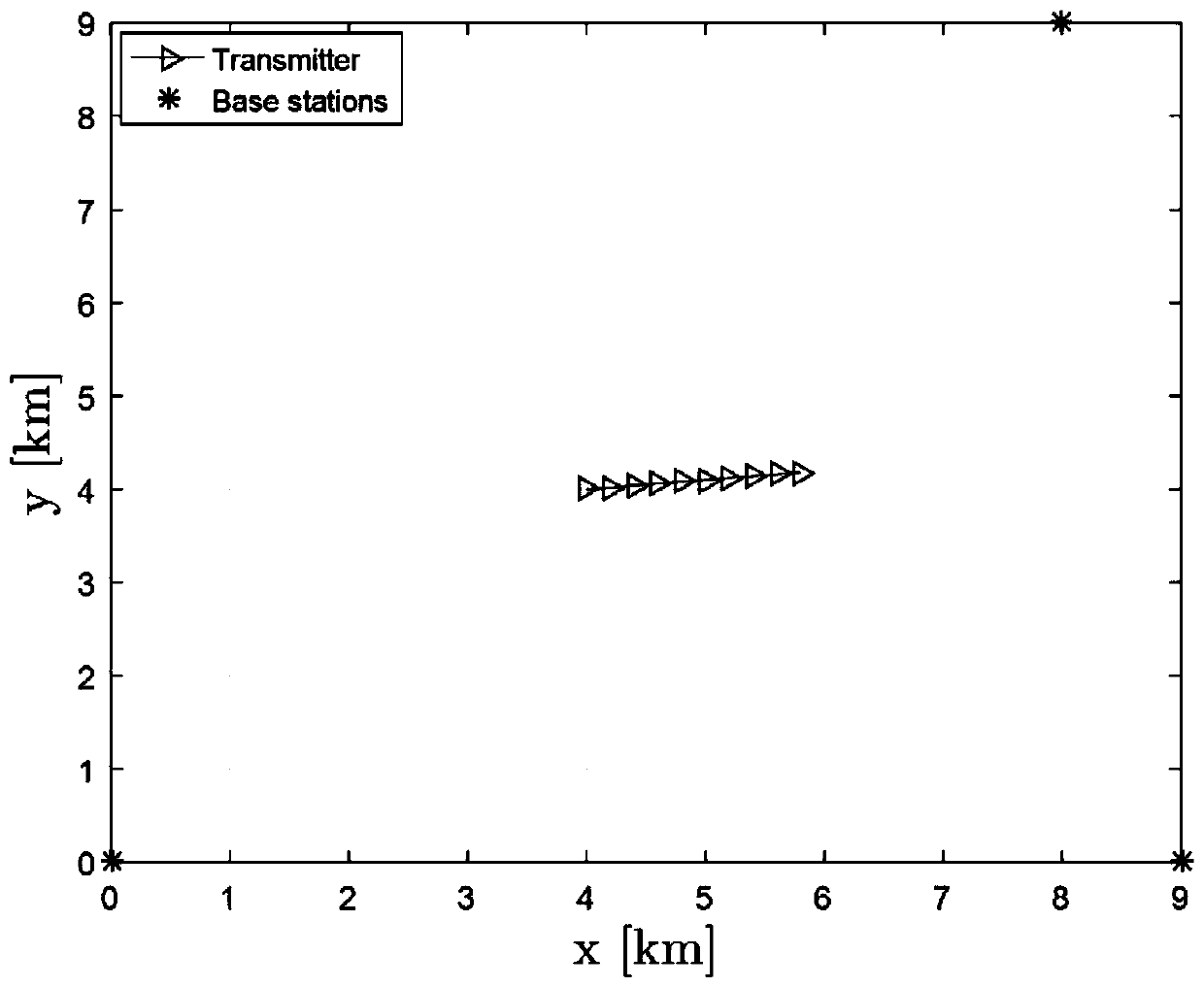

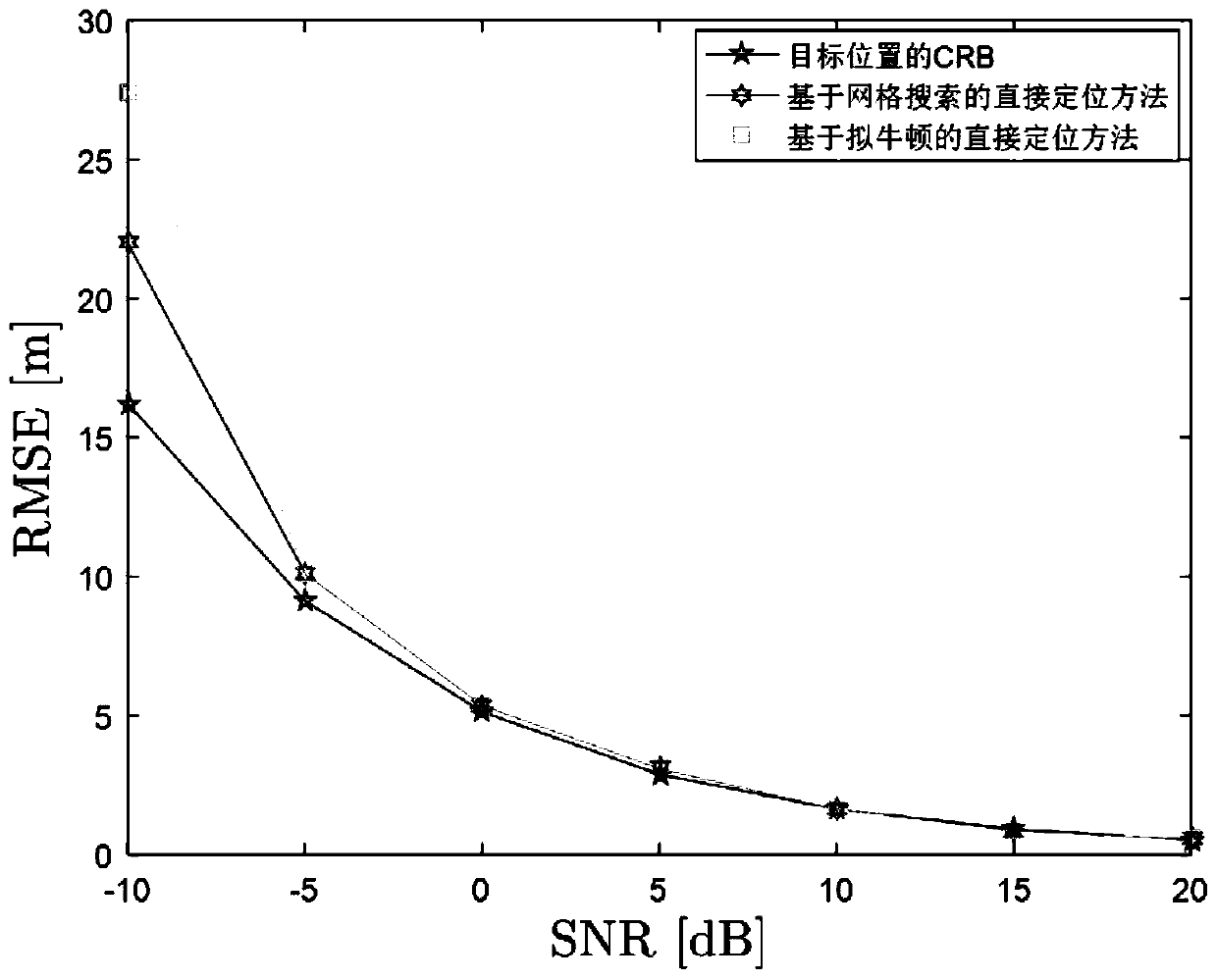

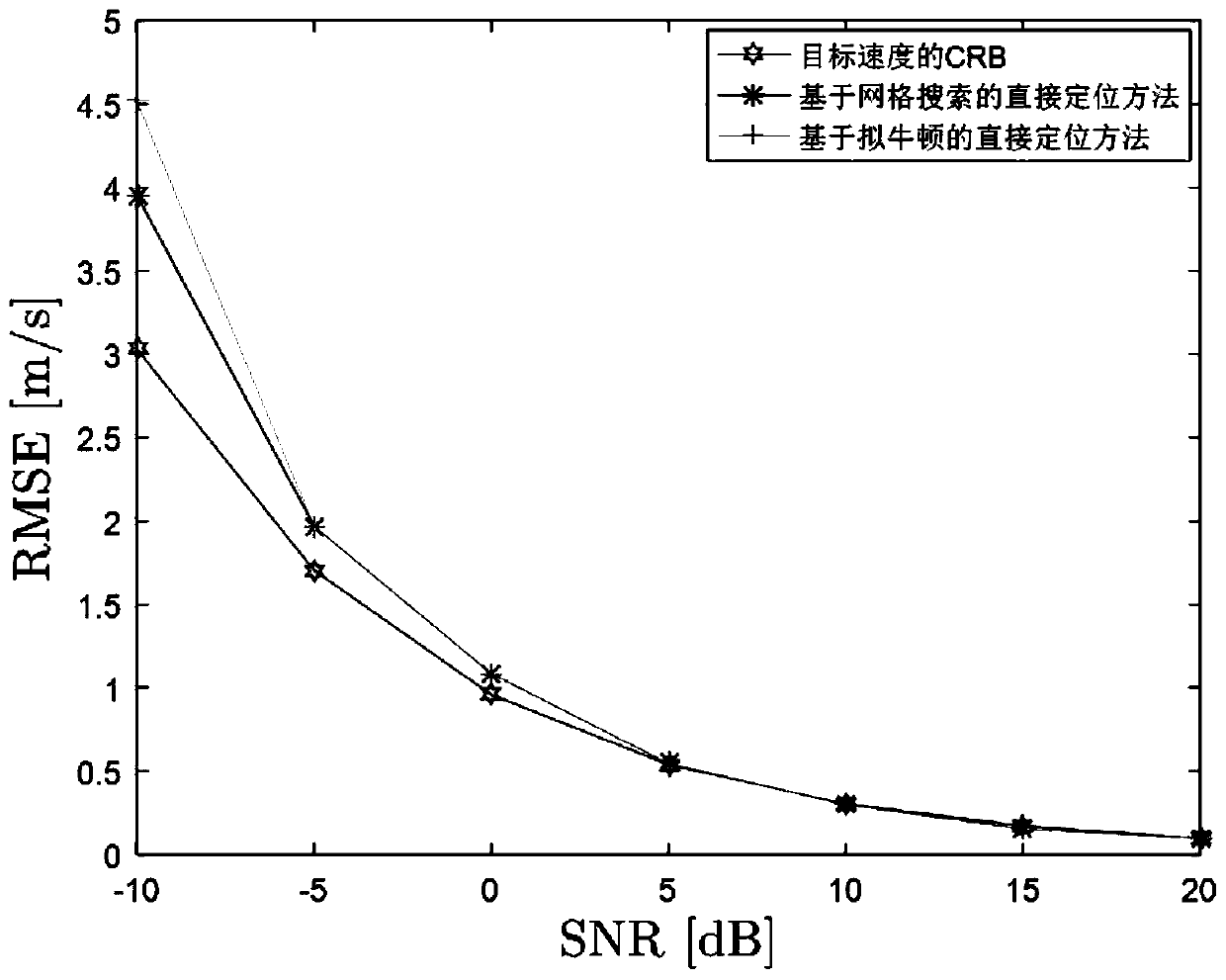

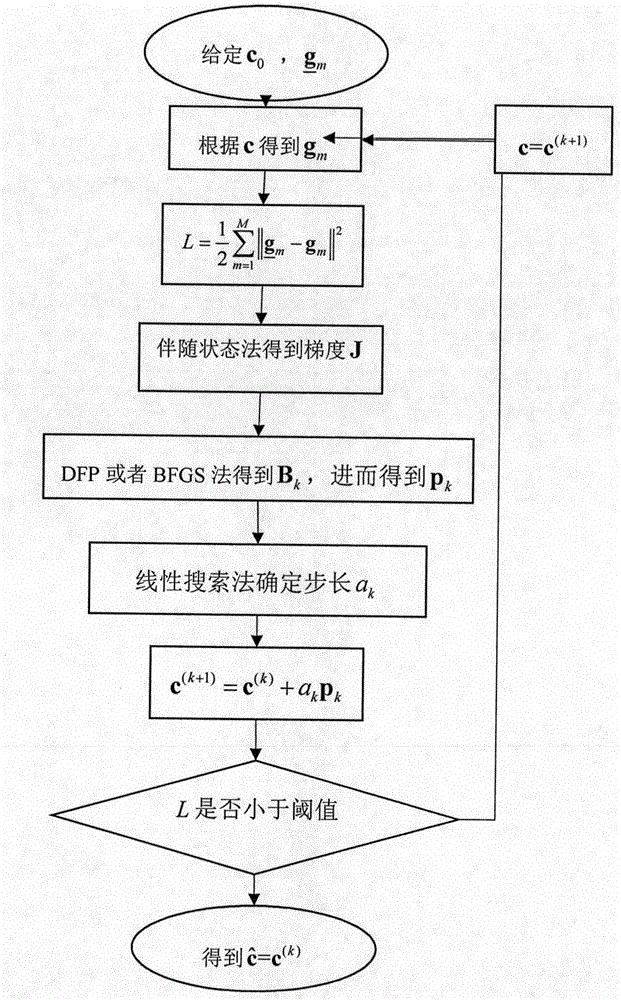

Moving target direct positioning method based on quasi-newton method

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for reconstructing sound velocity image by virtue of optimized full wave inversion method

InactiveCN106037795AImprove efficiencyReduce computing timeInfrasonic diagnosticsUltrasonic/sonic/infrasonic image/data processingFull waveData acquisition

The invention discloses a method for reconstructing a sound velocity image by virtue of an optimized full wave inversion method. The reconstruction method comprises the following steps: acquiring an actually measured sound pressure signal of the position where a sensor is located by virtue of ultrasonic data acquisition equipment; completely simulating a transmitting and receiving process on a computer so as to obtain a forward function, wherein an input variable of the function is a sound velocity image matrix and an output variable is the norm of a difference between a sound pressure signal, which is recorded on a corresponding position of the sensor, and the actually measured sound pressure signal; turning to an iterative process: providing a sound velocity image as an initial image, and introducing the initial image, as an independent variable, to the forward function, so that an output norm is obtained; calculating a first-order gradient image of the forward function on the position of a current sound velocity image; solving an optimization problem by virtue of a quasi-Newton method, and updating the original sound velocity images so as to obtain new sound velocity images; and repeating the iterative process by taking the new sound velocity images as initial images, and quitting the iterative process until conditions are met, so that a current sound velocity image is obtained.

Owner:NANJING UNIV

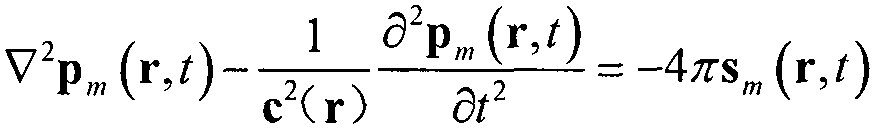

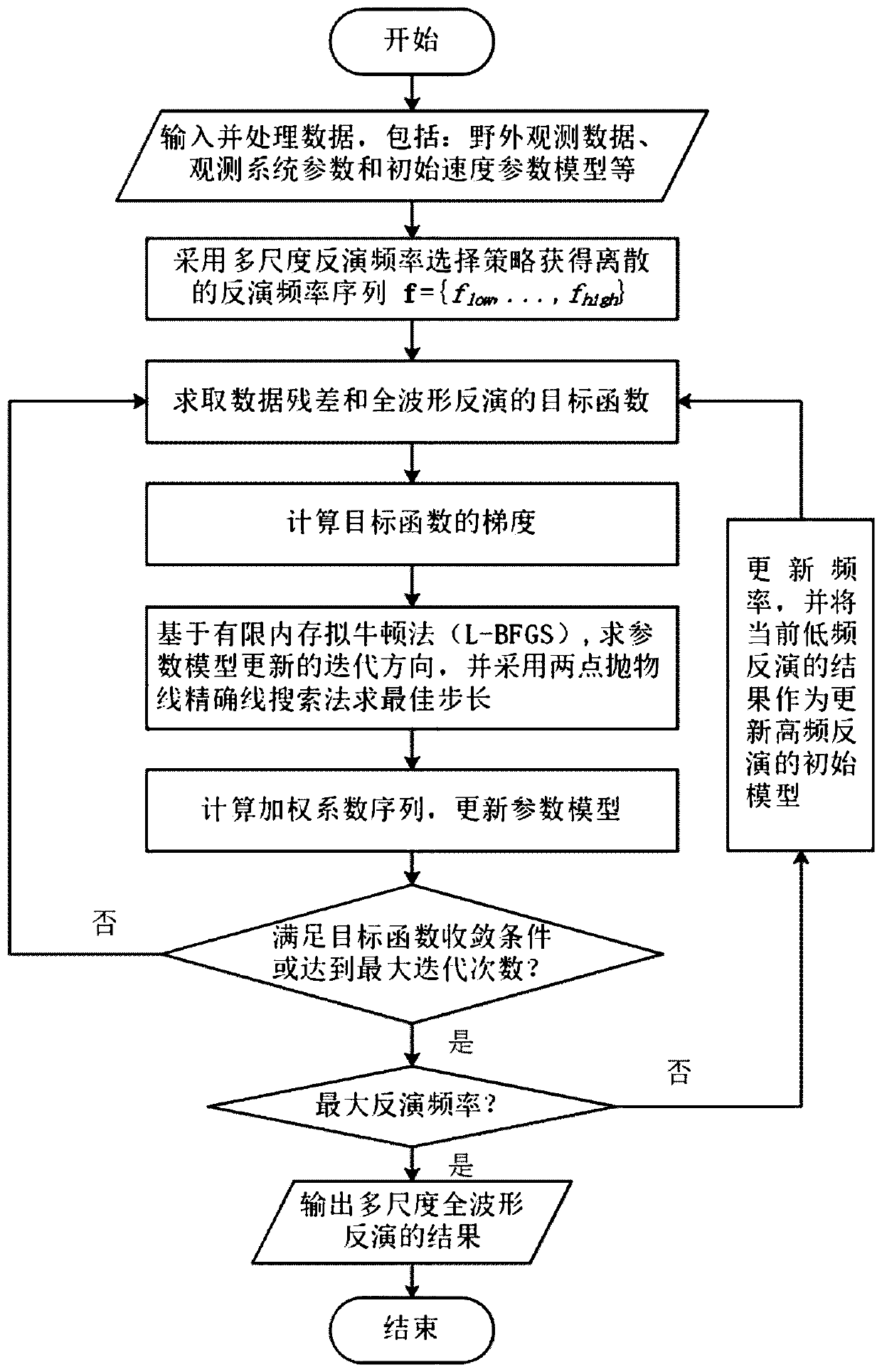

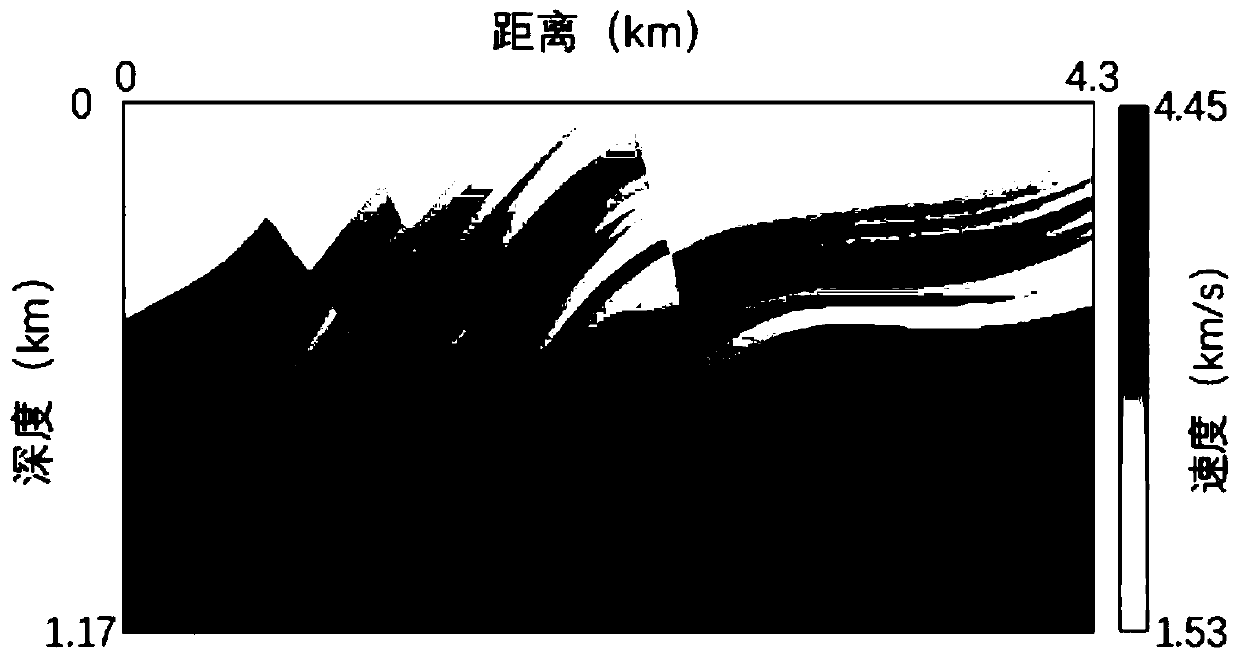

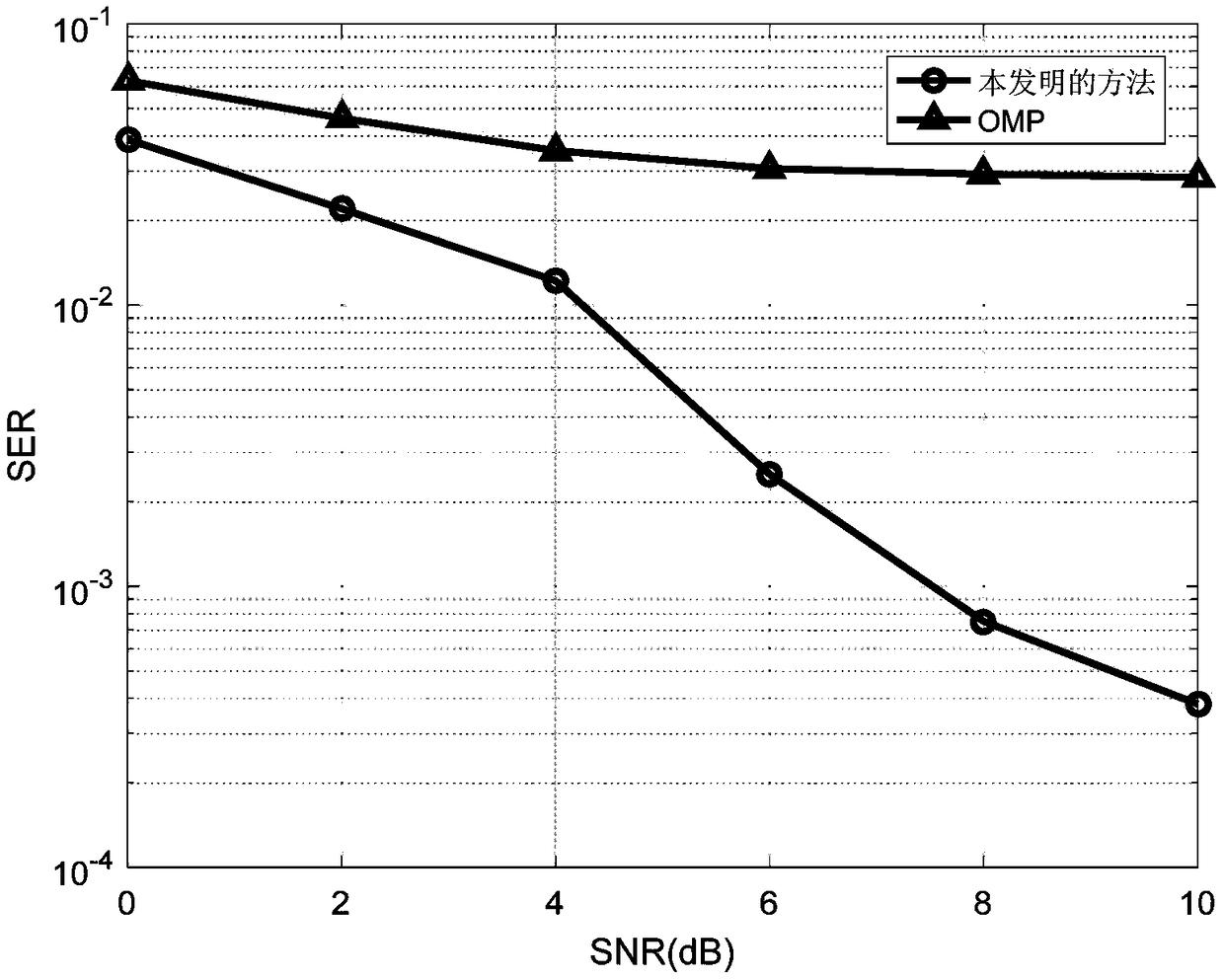

Rapid quasi-newton method-based full-waveform inversion method

InactiveCN110058307AFast convergenceSmall amount of calculationSeismic signal processingWeight coefficientFull wave

The invention discloses a rapid quasi-newton method-based full-waveform inversion method, belongs to the technical field of seismic exploration speed modeling, and aims at improving the convergence rate of a quasi-newton method so as to improve the calculation efficiency of seismic full-wave inversion and reduce the calculated amount. The method comprises the steps of defining a group of weightingcoefficient sequences to construct a parameter model iterative formula; importing a middle iterative parameter model and calculating a quasi-newton iterative direction and an optimum step length on the basis of the parameter model; and updating an original parameter model and the middle iterative parameter model by utilizing weighting coefficients, the iterative direction and the optimum step length. According to the method, calculation is carried out to obtain parameter models closest to optimum solutions, and the parameter models are used for the calculation of the next iteration directionand optimum step length, so that the convergence rates of target functions are improved. In the iterative calculation of each time, more calculated amount is not added in the method, and only a smallamount of multiplication and addition with relatively low complexity are carried out, so that the calculated amount of the full-waveform inversion is effectively reduced.

Owner:SICHUAN INST OF GEOLOGICAL ENG INVESTIGATION

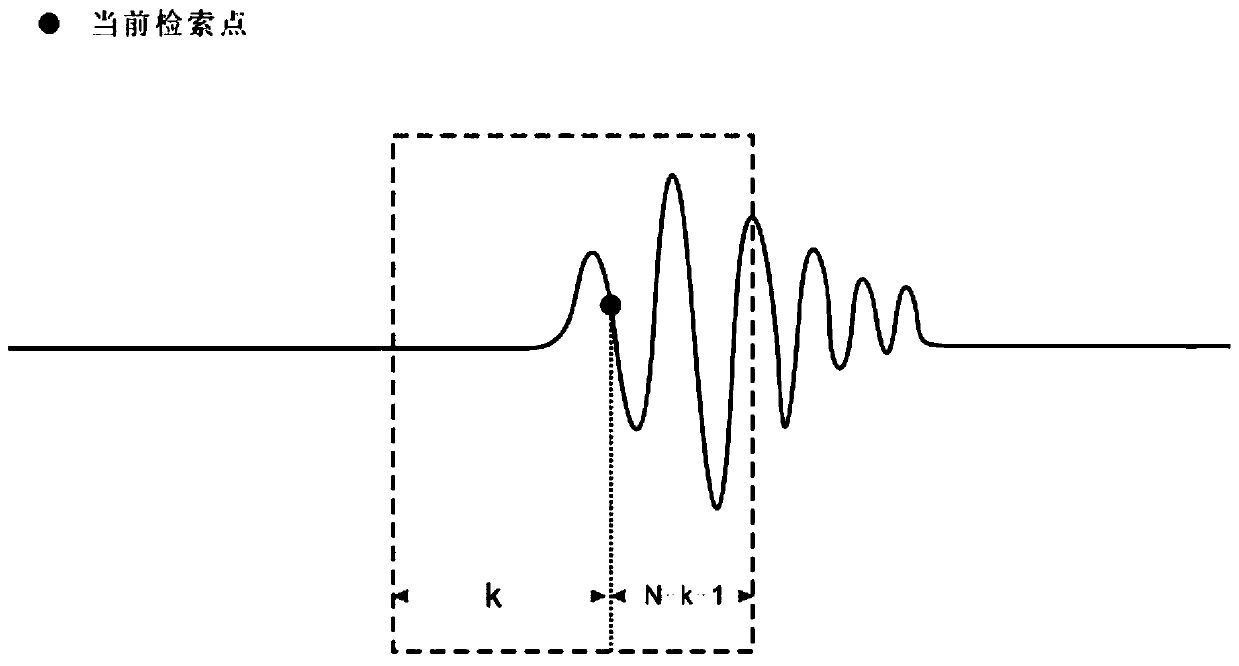

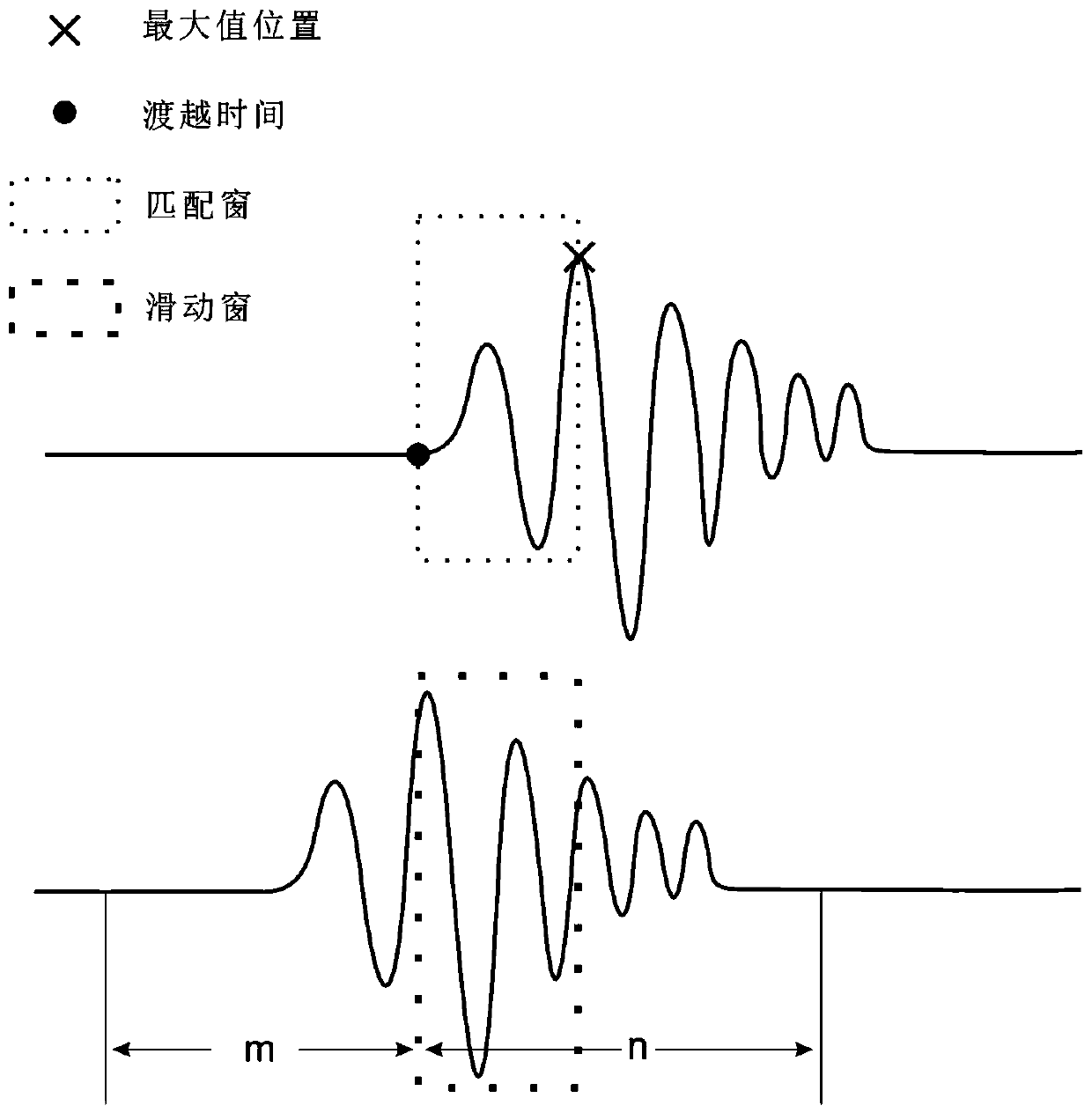

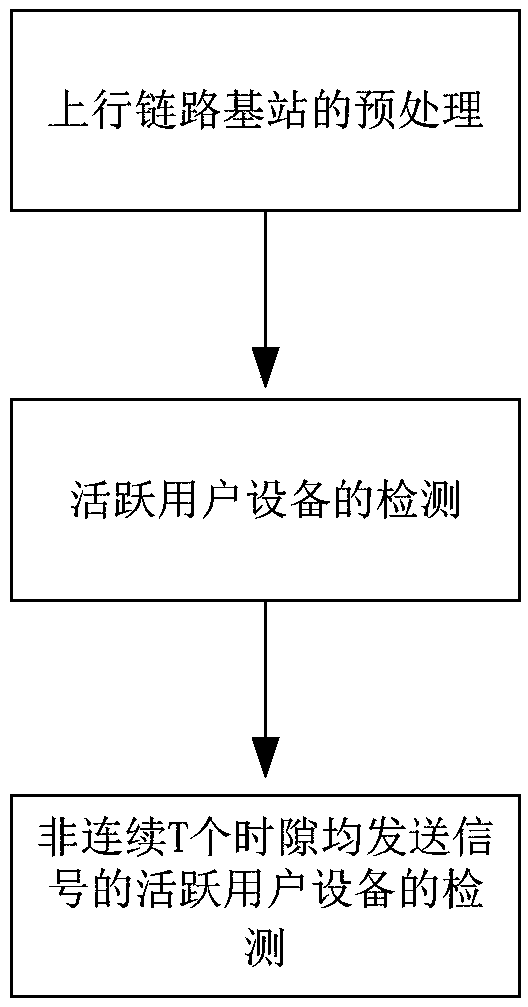

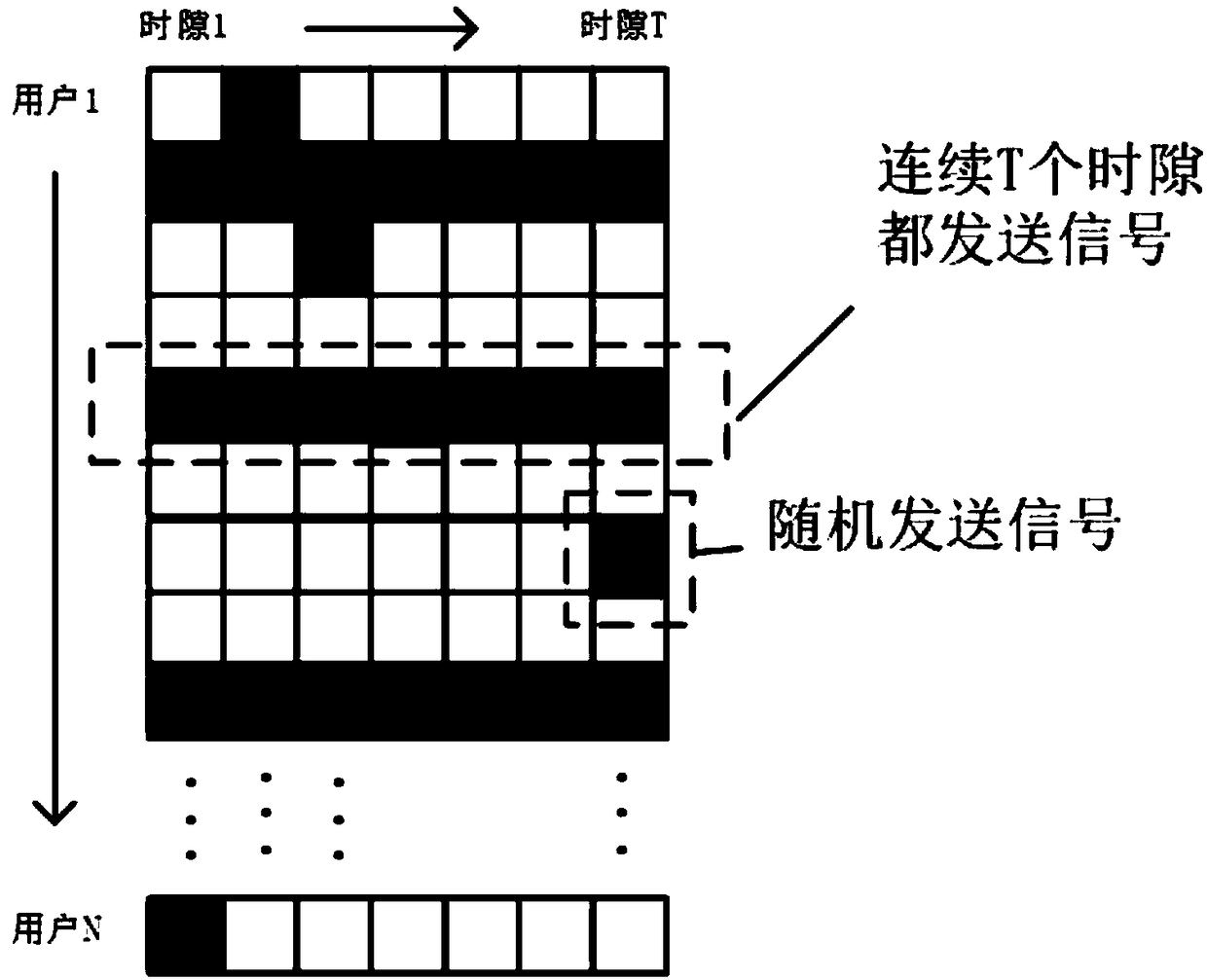

Multi-user detection method for non-orthogonal multiple access system on basis of gradient tracing and multi-step quasi-Newton method technology

ActiveCN109327850AHigh precisionSmall amount of calculationTransmission monitoringWireless communicationUser deviceMulti user detection

The invention relates to a multi-user detection method for a non-orthogonal multiple access system on basis of a gradient tracing and multi-step quasi-Newton method technology. Compared with the priorart, the defects that multi-user detection is heavy in computing burden, low in efficiency and poor in precision are overcome. The multi-user detection method comprises the following steps: preprocessing of an uplink base station, wherein the base station receives signals sent by user devices to acquire equivalence channel coefficients for iterative detection initialization; and detection of active user devices, wherein the active user devices which send signals at T continuous time slots in a signal frame and the sent signals of the devices are iteratively detected out. According to the multi-user detection method, the gradient tracing thought is introduced into multi-user detection of the base station, orthogonal projection computing when the user devices send signal estimation values is avoided, and a Hessian matrix that multi-step gradient information approximates a target function is computed by adopting a multi-step quasi-Newton method; and on one hand, the second-order convergence is introduced, the precision of multi-user detection is improved, and on the other hand, the convergence speed is increased, and the computing burden of multi-user detection is reduced.

Owner:ANHUI UNIVERSITY

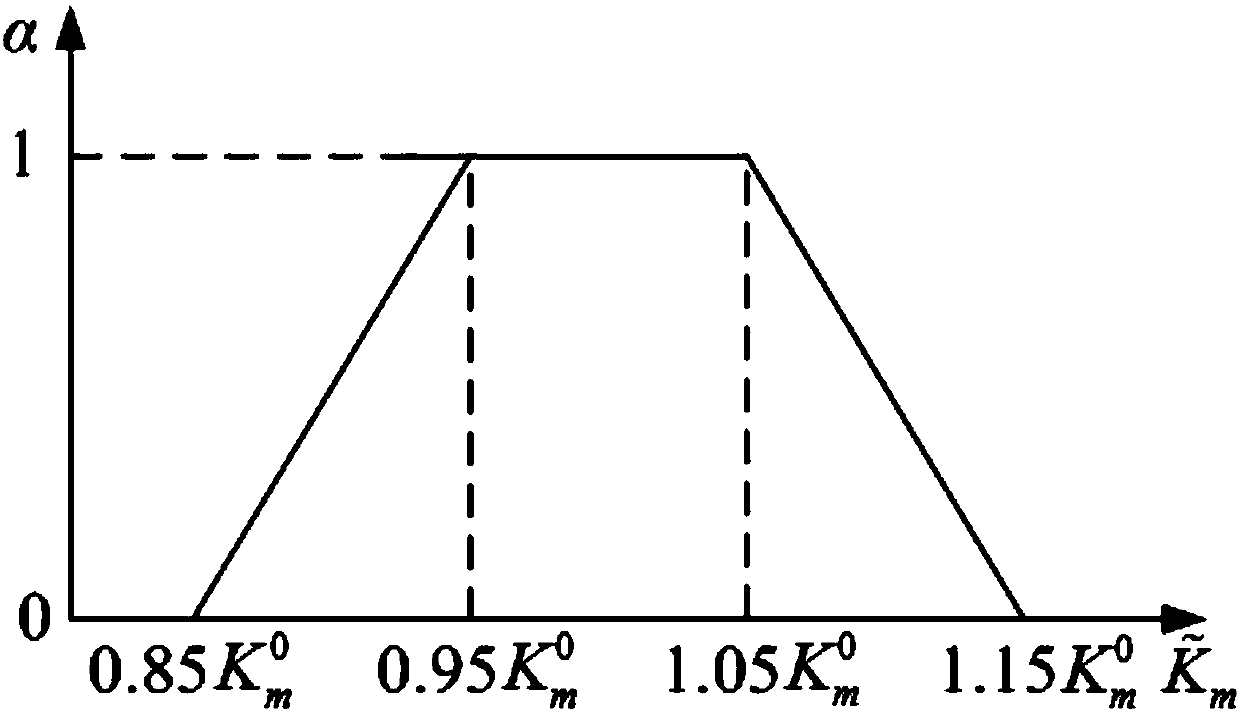

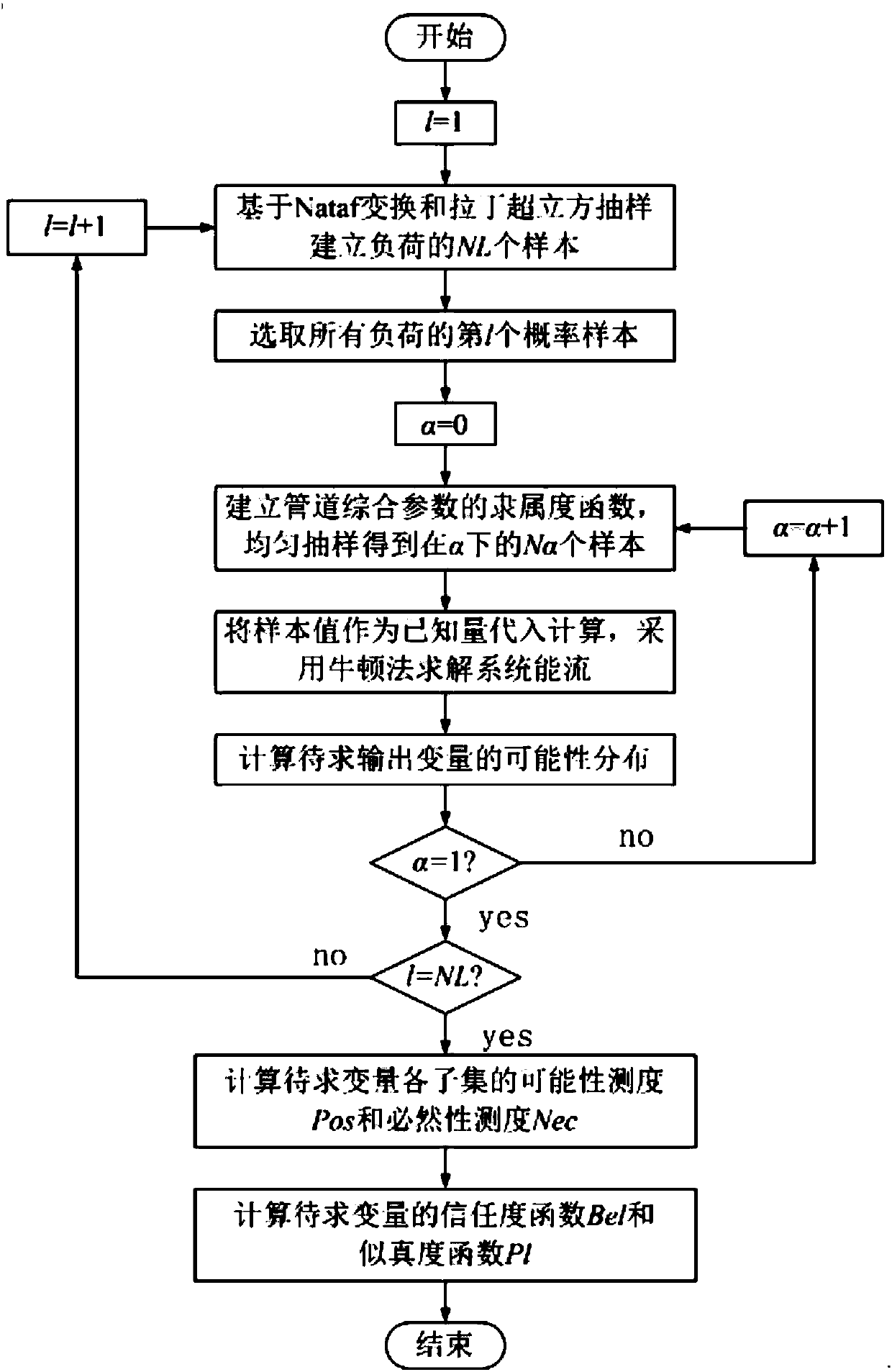

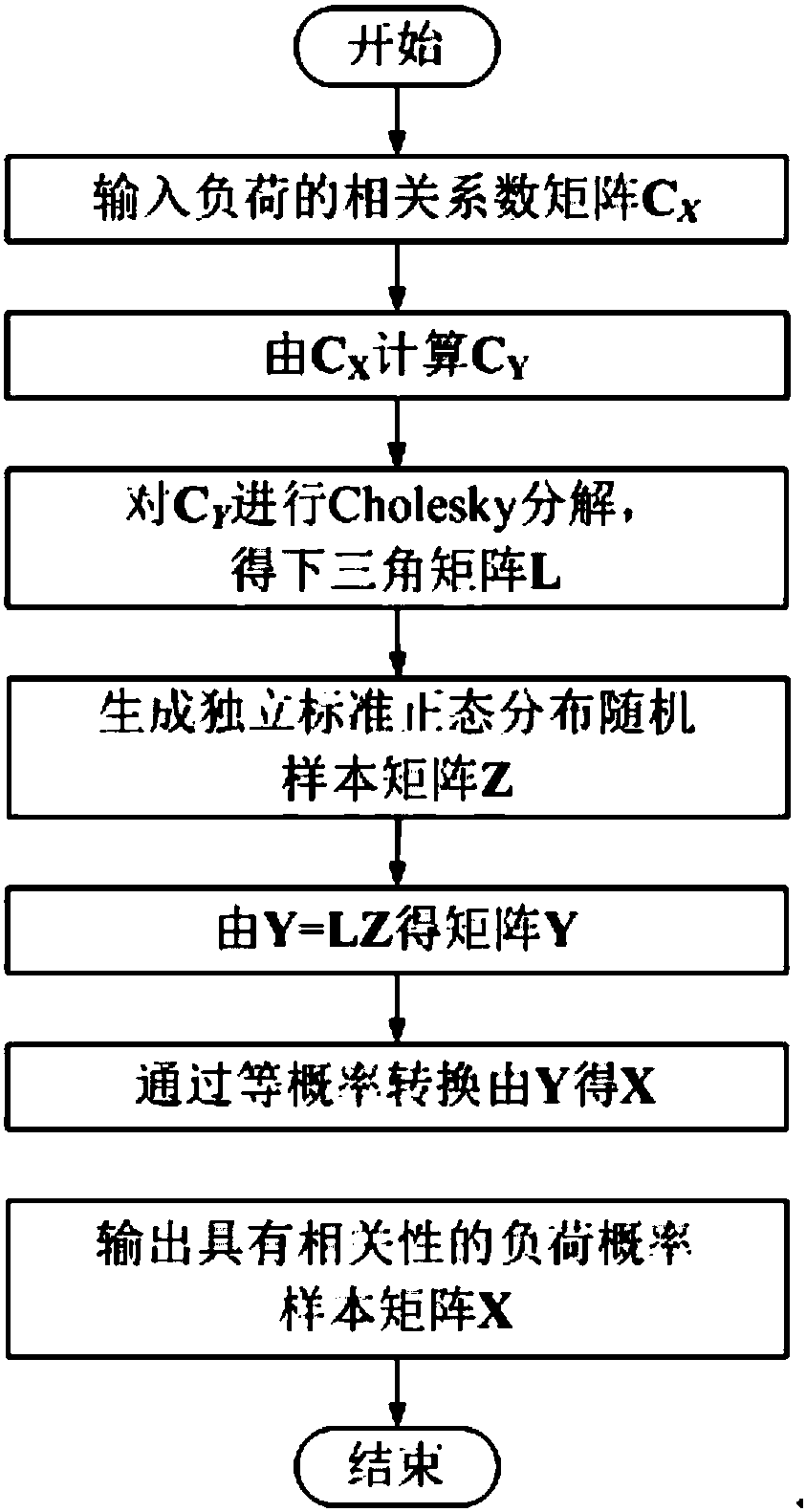

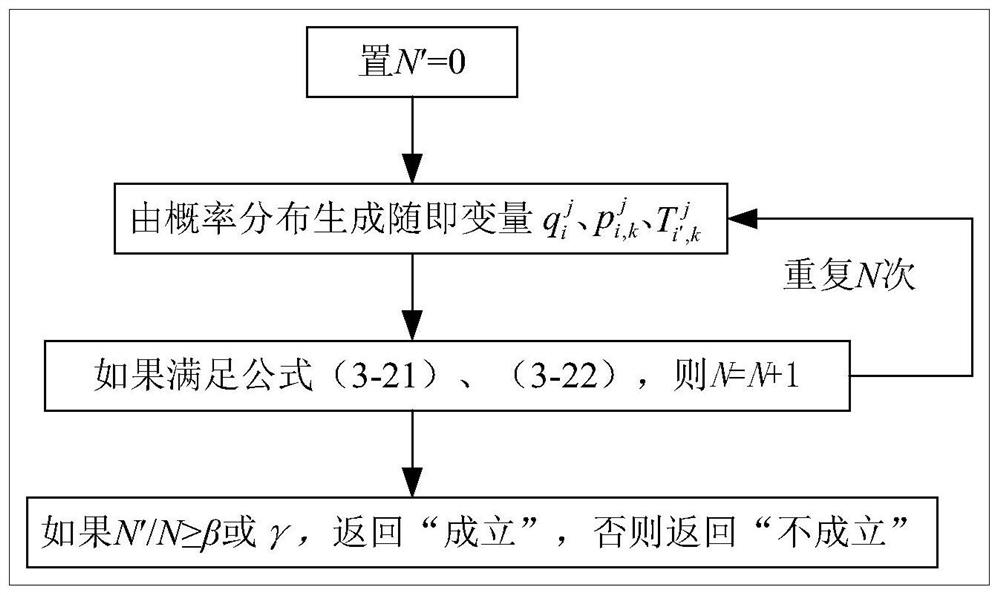

Multiple uncertainties-considered natural gas probability-fuzzy energy flow analysis method

ActiveCN108389136AEffective calculationAccurate calculationData processing applicationsDesign optimisation/simulationNODALEnergy flow analysis

The invention discloses a multiple uncertainties-considered natural gas probability-fuzzy energy flow analysis method. The method mainly comprises the following steps of: 1) establishing a natural gassystem model; 2) establishing a probability model of non-equilibrium node loads; 3) sampling the probability model of the non-equilibrium node loads by utilizing a Latin hypercube method, so as to obtain an N*NL-dimensional load probability sample matrix; 4) establishing a fuzzy model of pipeline comprehensive parameters; 5) sampling the fuzzy model of the pipeline comprehensive parameters by utilizing a <alpha>-cut set method; 6) calculating a pipeline energy flow and pipeline non-equilibrium node bearing pressure in the natural gas system by utilizing a newton method; and 7) calculating a possibility measure Pos and a necessity measure Nec of an output variable, so as to obtain a credibility function Bel and a verisimilitude function Pl of the output variable. The method combines the influences of two uncertain factors such as probability and fuzziness, and is capable of effectively and correctly calculating change ranges of output variables of natural gas systems.

Owner:CHONGQING UNIV

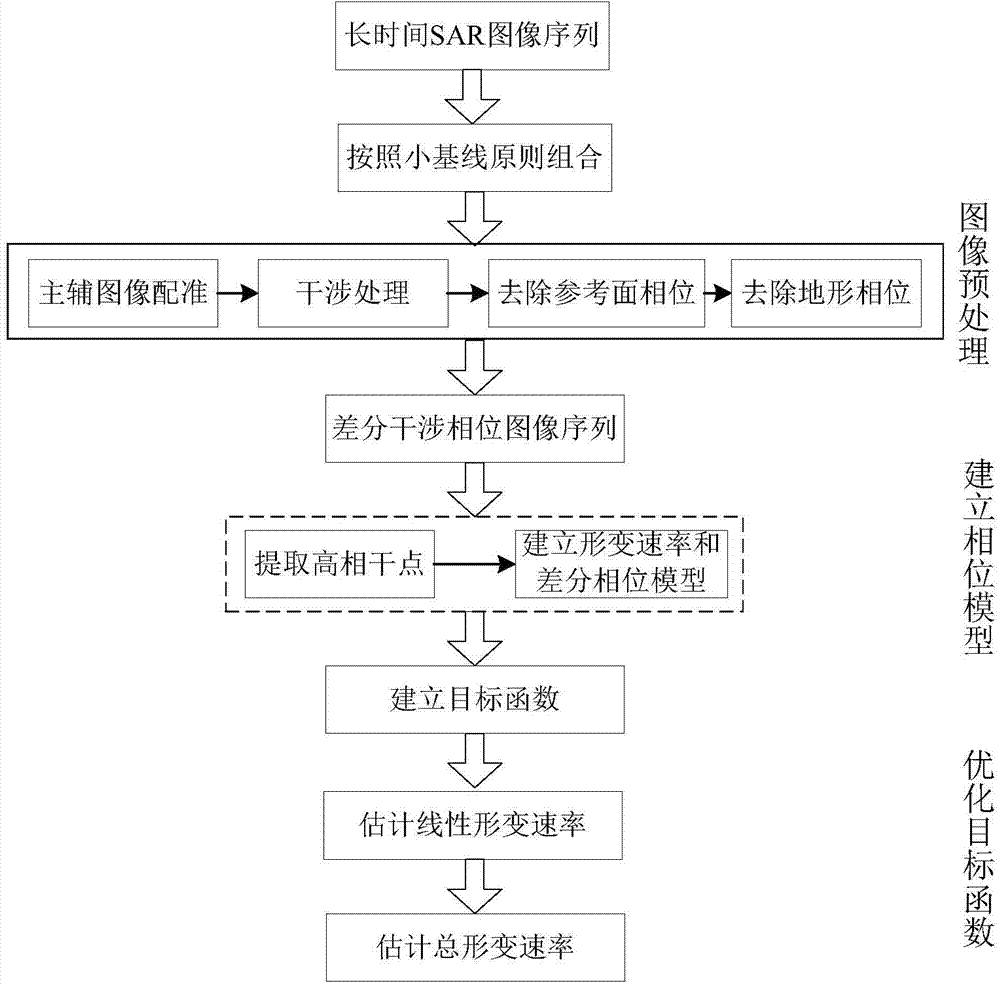

SBAS-DInSAR method based on nonlinear optimization strategy

The invention discloses an SBAS-DInSAR method based on a nonlinear optimization strategy, and relates to the technical field of radar. The method can achieve resolving of an equation without phase unwrapping, an optimization object function relative to a surface deformation rate is constructed through establishing a winding differential interferometry phase nonlinear model, the equation is resolved through a quasi-Newton method, surface deformation information is extracted, and a novel SBAS-DInSAR surface deformation measuring method is achieved. According to the SBAS-DInSAR method based on the nonlinear optimization strategy, an error introduced by a phase unwrapping algorithm is avoided, and deformation calculation efficiency is improved simultaneously; under the circumstance of only using a winding phase, a high-precision surface deformation result can be obtained, and a novel way is provided for surface deformation measurement.

Owner:BEIHANG UNIV

Passenger vehicle real-time scheduling method based on random opportunity constraints

InactiveCN112562377ADetection of traffic movementCharacter and pattern recognitionVehicle dynamicsLocal optimum

The invention provides a vehicle dynamic scheduling method applying opportunity constraint planning. The method includes the steps of adopting a Fisher ordered clustering analysis algorithm to divideall-day time into a plurality of sub-periods with equal departure intervals, establishing a model according to random system constraint conditions of passenger waiting time and vehicle capacity, checking the random system constraint conditions, calculating a target value in the model, and solving an optimal value based on a stochastic simulation genetic algorithm, thereby determining a multi-time-period real-time scheduling scheme. According to the opportunity constraint-based real-time scheduling model, an optimization objective function and constraint conditions of scheduling decisions underthe condition that uncertain events such as passenger flow randomness, accidents and congestion occur are solved, the optimal solution of the decisions is determined by adopting a genetic algorithm and random simulation, and the problems that an analytical solution of a traditional optimization algorithm such as a quasi-Newton method is difficult to express and is liable to fall into a local optimal solution are solved.

Owner:XIAMEN UNIV +2

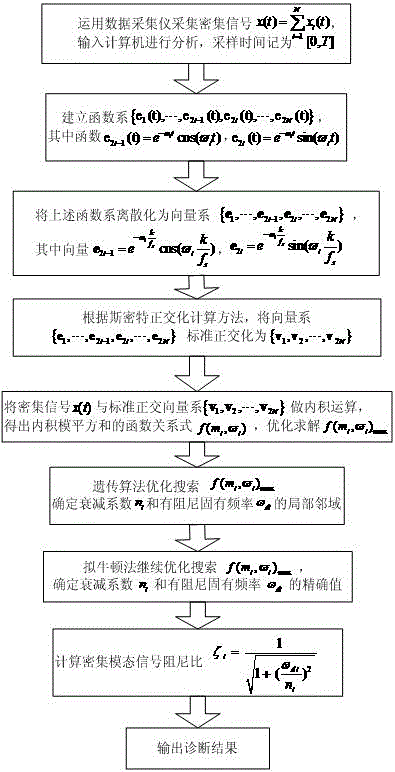

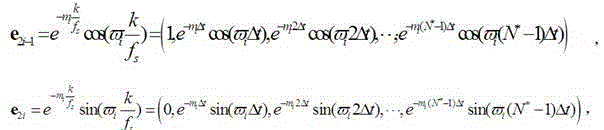

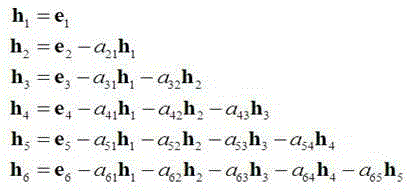

Closely spaced mode damping ratio precisely-diagnosing method

InactiveCN103605880AAccurate diagnosisStrong engineering practicabilitySpecial data processing applicationsAttenuation coefficientGenetic algorithm

The invention discloses a closely spaced mode damping ratio precisely-diagnosing method. The method comprises constructing a standard orthogonal system through a Schmidt orthogonalization calculation method according to the number of orders of closely spaced modes and then performing inner product operation on closely spaced mode signals and the standard orthogonal system; obtaining the attenuation coefficient and the inherent frequency of every order of the closely spaced mode signals according to the Bessel inequation theorem when the closely spaced mode signals have the maximum projection in the standard orthogonal system, namely, when inner product modular square sum is maximized, wherein the maximum value of the inner product modular square sum is obtained through optimizing search of the genetic algorithm and the Newton method; obtain the damping ratio of every order of the mode through the relation of the attenuation coefficient, the inherent frequency and the damping ratio. According to the closely spaced mode damping ratio precisely-diagnosing method, the diagnosing process only requires a limited section of signals, identification is performed by performing the inner product operation on the closely spaced mode signals and the constructed standard orthogonal system, accordingly the limit of the number of orders of the modes and the size of the damping value can be avoided, and the diagnosing results are accurate; besides, the closely spaced mode damping ratio precisely-diagnosing method is also applicable to the damping identification of non-closely spaced mode signals.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com