Gold stamping machine

A technology of a bronzing machine and a feeding mechanism, which is applied in the field of bronzing machines, can solve the problems of low production efficiency, determination only after manual measurement, and low machining accuracy of workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

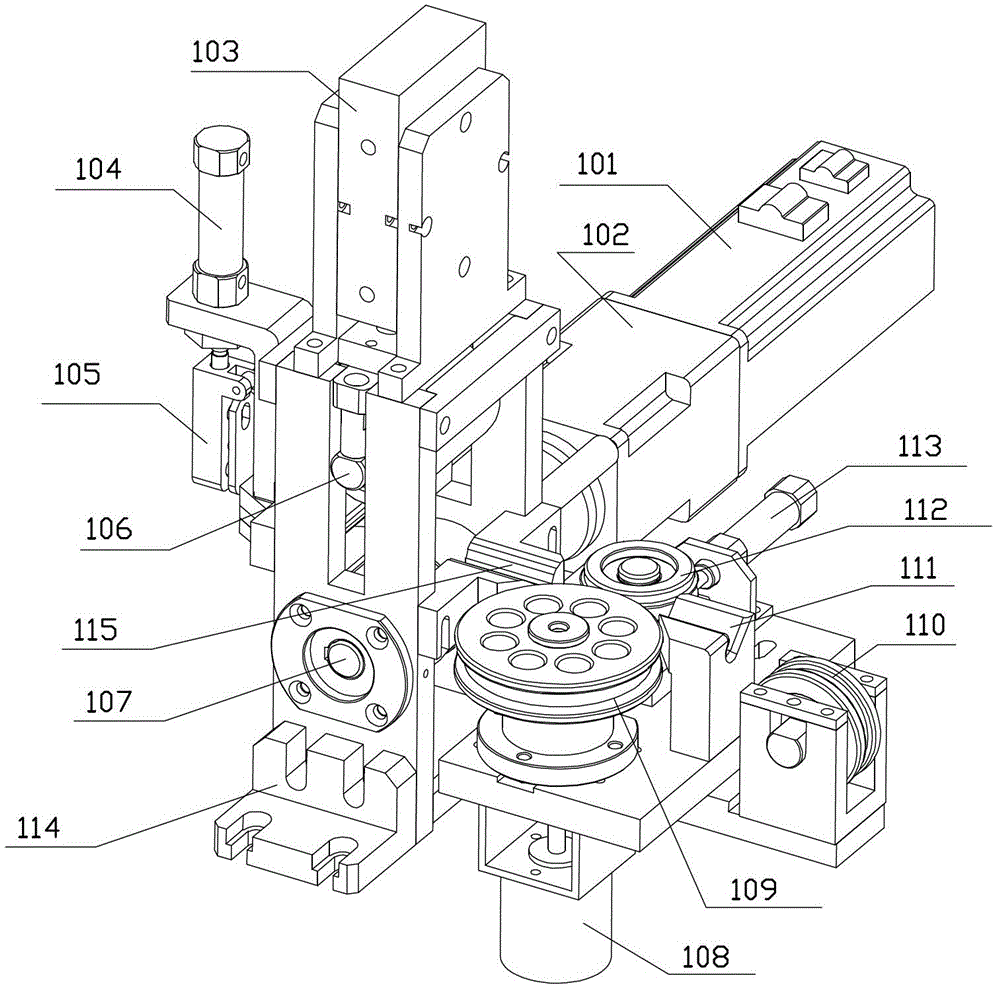

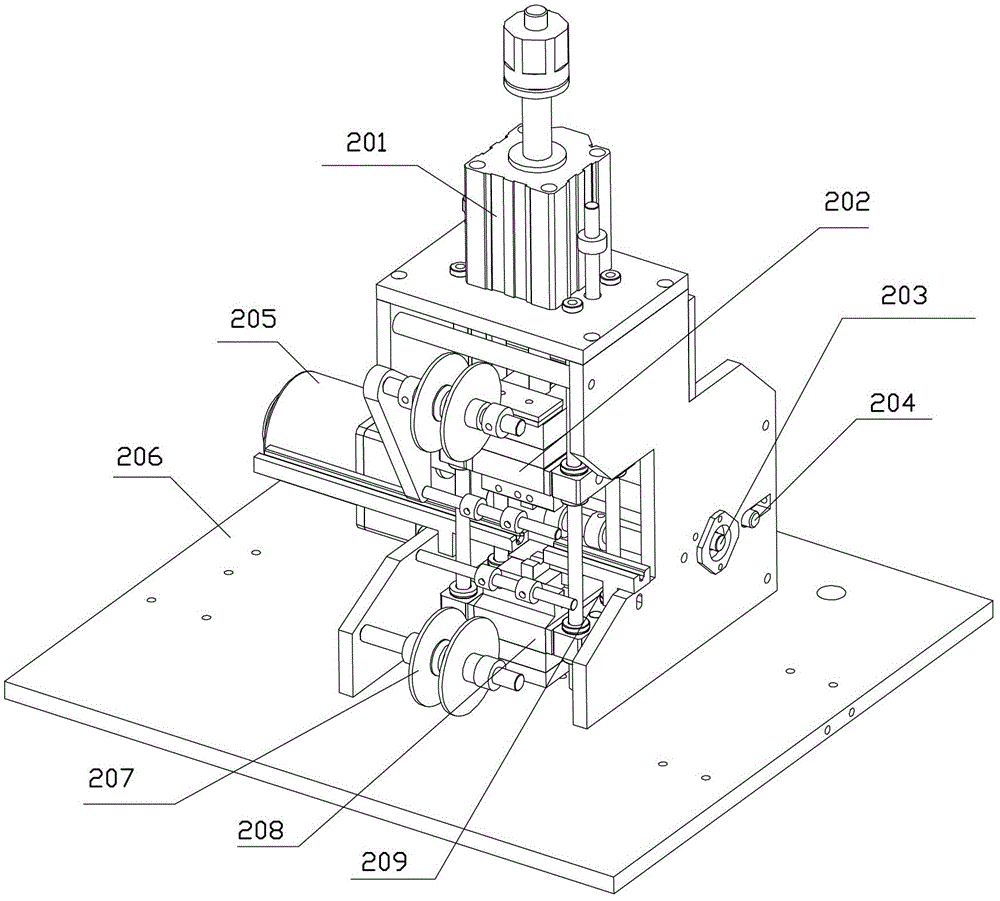

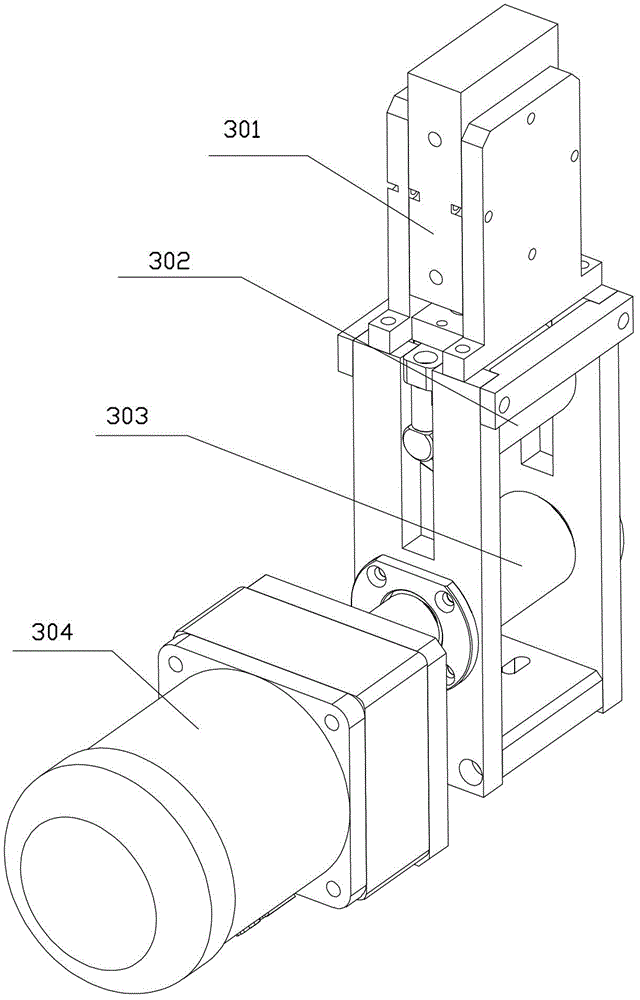

[0021] combined with figure 1 to attach Figure 8, a kind of hot stamping machine, it comprises hot stamping part 2, and described hot stamping part 2 is provided with feed inlet, discharge port and bottom plate 206, and it also includes feeding mechanism 1, tail material output mechanism 3 and main controller, feeding Mechanism 1 and tail material output mechanism 3 are all installed on the base plate 206, and described feeding mechanism 1 joins with described feed inlet, and described tail material output mechanism 3 joins with described discharge outlet, feeds The electric control components on the mechanism 1 and the tailing output mechanism 3 are all electrically connected with the main controller. The feeding mechanism 1 includes a first motor 101, a first pressing cylinder 103, a positioning cylinder 104, a start switch 105, a first driven wheel 106,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com