Conveyer belt adjuster

An adjustment device and conveyor belt technology, which is applied in the field of conveyor belts, can solve problems such as low tensile strength, jumping, and poor flatness, and achieve the effects of improving accuracy and efficiency, reducing offset, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Several embodiments of the present invention are discussed in detail below with reference to the accompanying drawings.

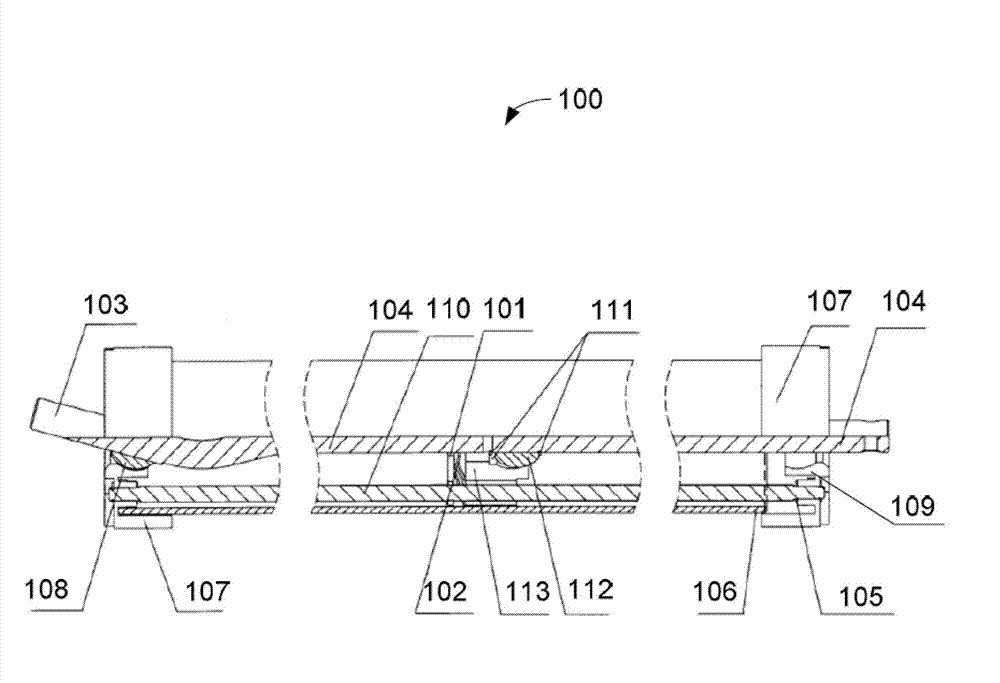

[0021] figure 1 The main structure of the conveyor belt adjusting device of the present invention is shown. Such as figure 1 As shown, the conveyor belt adjustment device 100 of the present invention mainly includes: a roller 101, a roller center kit 102, a roller spindle 103, a main kit 104, a locking member 105, a disc-shaped pressing plate 106, a disc-shaped baffle 107, a first roller Drum end kit 108 , second drum end kit 109 , connecting part 110 .

[0022] A roller center sleeve 102 is arranged at the middle position of the roller 101 .

[0023] One side of the roller spindle 103 is inclined upward.

[0024] The main sleeve 104 is sleeved outside the axis center of the roller main shaft 103 , wherein the main sleeve 104 is further sleeved inside the roller center sleeve 111 . Preferably, according to the present invention, an elastic ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com