Application of hydrophobic material

A hydrophobic and soft technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc. Large contact area, increased dissolved oxygen, and uniform distribution of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

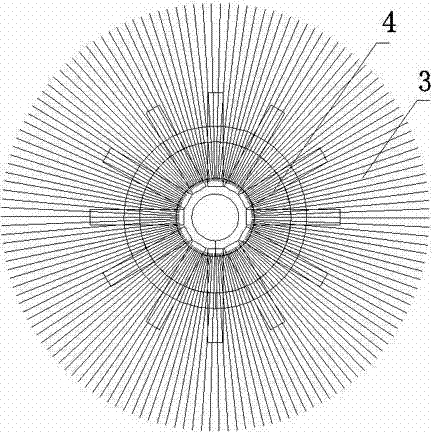

[0029] An application of a hydrophobic material, the hydrophobic material is applied to a biological filler, and the reoxygenation function of the biological filler is improved.

[0030] In the present invention, the hydrophobic material refers to a hydrophobic material with a wetting angle greater than 90° and a porosity preferably greater than 10%.

[0031] The invention mainly utilizes that the hydrophobic material has weak affinity with water and is repellent to water, thereby forming a gas film in the water, increasing the gas-liquid contact time and contact area, thereby increasing the dissolved oxygen in the water. The invention uses hydrophobic materials to replace traditional polyethylene / polypropylene and other materials as a biological filler bracket or shell to form a combined filler, which is applied to a dispersed non-powered or micro-powered sewage treatment device. When this combined filler is added to water, the porous hydrophobic material will bring air into ...

Embodiment 2

[0038] The hydrophobic material is made into a supporting structure, a partition or an airflow uniform structure of the biological filler, and is applied in the facultative or aerobic area of the sewage purification system.

[0039] Further, the supporting structure may be a scaffold or a shell, and the scaffold or shell of the biological filler is made of hydrophobic material.

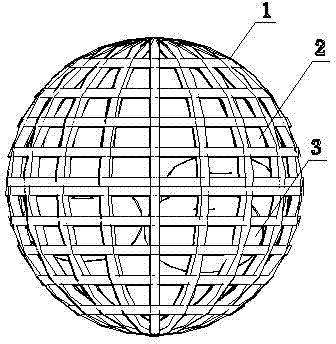

Embodiment 3

[0041] When the biological filler is a suspended biological filler, the shell of the suspended biological filler is made of hydrophobic material, used in combination with the suspended biological filler, and added to the facultative or aerobic zone of the sewage purification system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com