High-strength temperature resistant viscoelastic polymer for profile control

A polymer, high-strength technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as shear sensitivity, and achieve the effects of low environmental toxicity, excellent stability, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Solution preparation: Add 525.2g of deionized water into a beaker, add 168g of 2-acrylamido-2-methyl-1-propanesulfonic acid monomer and 92g of 2-acrylamido dodecanesulfonic acid in sequence, and stir well Use sodium hydroxide to adjust the pH value to about 6.5, add 195g of acrylamide, 5g of fluorine-containing methyl acrylate, 2g of N-vinylacetamide, dimethyl[2-(methacryloyloxy)ethyl][3 -(Trimethoxysilylpropyl)] ammonium chloride 12g, ammonium carbonate 0.8g, stir evenly, and adjust the temperature between 13±1°C.

[0047] Polymerization of the solution: Blow nitrogen to remove oxygen for 30-40 minutes, add the initiator ammonium persulfate, pass nitrogen for 15 minutes, add the initiator sodium formaldehyde bisulfite, continue to pass nitrogen, when the temperature rises by 2°C during the induction period, stop nitrogen, After 5 hours of reaction, shear, dry, and granulate to obtain the finished product.

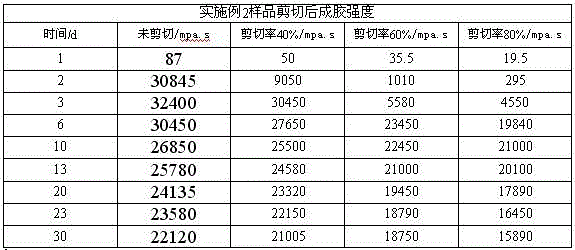

Embodiment 2

[0049] Preparation of the solution: Add 320g of deionized water into a beaker, add 550g of 2-acrylamido-2-methyl-1-propanesulfonic acid monomer, 20g of 2-acrylamido dodecanesulfonic acid in turn, stir well and use Adjust the pH value to about 6.5 with sodium hydroxide, add 50g of acrylamide, 30g of fluorine-containing methyl acrylate, dimethyl[2-(methacryloyloxy)ethyl][3-(trimethoxysilylpropyl)] Ammonium chloride 50g, ammonium carbonate 0.1g, stir evenly and adjust the temperature between 13±1°C.

[0050] Polymerization of the solution: Blow nitrogen to remove oxygen for 30-40 minutes, add the initiator ammonium persulfate, pass nitrogen for 15 minutes, add the initiator sodium formaldehyde bisulfite, continue to pass nitrogen, when the temperature rises by 2°C during the induction period, stop nitrogen, After 5 hours of reaction, shear, dry, and granulate to obtain the finished product.

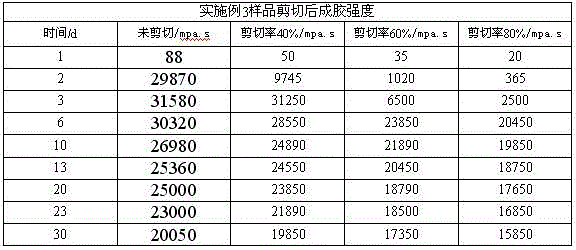

Embodiment 3

[0052] Preparation of the solution: Add 250g of deionized water into a beaker, add 50g of 2-acrylamido-2-methyl-1-propanesulfonic acid monomer, 150g of 2-acrylamido dodecanesulfonic acid in turn, stir well and use Adjust the pH value to about 6.5 with sodium hydroxide, add 600g of acrylamide, 20g of dimethyl[2-(methacryloyloxy)ethyl][3-(trimethoxysilylpropyl)]ammonium chloride, and ammonium carbonate 10g, stir evenly and adjust the temperature between 13±1°C.

[0053]Polymerization of the solution: Blow nitrogen to remove oxygen for 30-40 minutes, add the initiator ammonium persulfate, pass nitrogen for 15 minutes, add the initiator sodium formaldehyde bisulfite, continue to pass nitrogen, when the temperature rises by 2°C during the induction period, stop nitrogen, After 5 hours of reaction, shear, dry, and granulate to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com