High-polymer electrothermal film and preparation technique thereof

A preparation process and electric heating film technology, which is applied in the field of materials, can solve the problems of affecting service life, poor thermal stability, and decreased conductivity, and achieve the effects of not easy aging, long service life, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

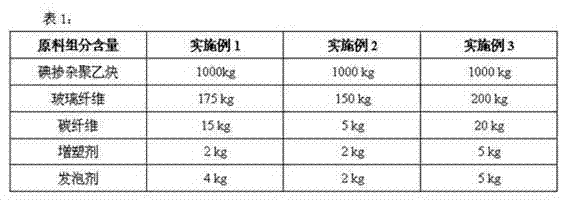

[0017] A polymer electric heating film, according to the raw material formula indicated in Table 1, its preparation process is as follows: Step 1, weigh each component raw material according to the formula amount, mix evenly, heat until the raw material temperature reaches 120 ° C, and dry until the raw material Granular;

[0018] Step 2: Blow-molding the dried mixture at 180° C. to obtain a polymer electric heating film.

Embodiment 2

[0020] A kind of macromolecule electrothermal film, according to the raw material formula indicated in table 1, its preparation process is as follows:

[0021] Step 1. Weigh the raw materials of each component according to the formula, mix them evenly, heat until the temperature of the raw materials reaches above 120°C, and dry until the raw materials are granular;

[0022] Step 2: Blow-molding the dried mixture at 170° C. to obtain a polymer electric heating film.

Embodiment 3

[0024] A kind of macromolecule electrothermal film, according to the raw material formula indicated in table 1, its preparation process is as follows:

[0025] Step 1. Weigh the raw materials of each component according to the formula, mix them evenly, heat until the temperature of the raw materials reaches above 120°C, and dry until the raw materials are granular;

[0026] Step 2: Blow-molding the dried mixture at 160°C to obtain a polymer electric heating film.

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com