Head-reconfigurable modular control system for flat knitting machines

A technology of modular control and group control, applied in textile and papermaking, weft knitting, knitting and other directions, can solve the problem of low knitting efficiency of flat knitting machine with single loop forming head system, and the system stability and reliability cannot be guaranteed. , The problems of different looping head systems and machines cannot be used to achieve the effect of improving the good rate and production efficiency, improving the weaving efficiency and fabric good rate, and improving the scalability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

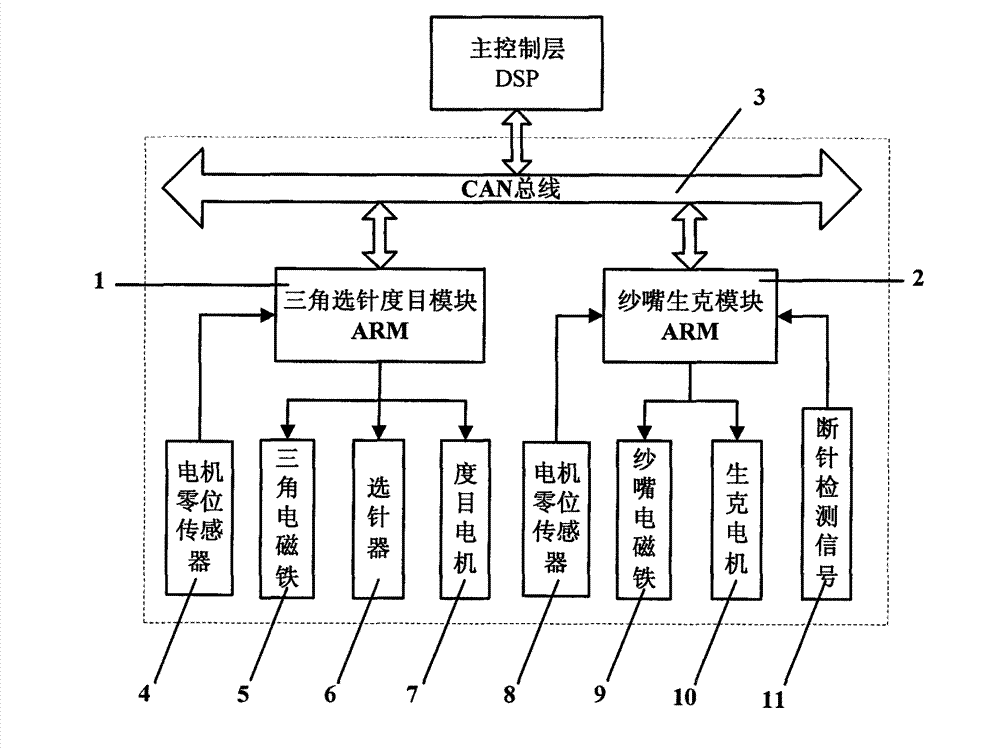

[0012] Embodiment 1: A reconfigurable modular control system for a flat knitting machine head, which includes one or more sets of control units. For the single knitting head system, the double knitting head system and the three knitting head system, there are respectively one set of control units, two sets of control units, and three sets of control units. For multi-knitting head systems, the number of control units corresponds to the number of knitting.

[0013] Each group of control units includes four triangular needle selection and stitch circuit modules (circuit module board 1 for triangular needle selection and stitch purpose) and a yarn feeder gramming circuit module (that is, the circuit for yarn feeder gramming) connected through CAN bus communication. Module board 2).

[0014] Each group of control units (triangular needle selection stitch circuit module, yarn feeder sinker circuit module) can form a communication connection with the general control module on the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com