Spiral Clutch Ice Scraper

A clutch-type, screw-type technology, applied in cleaning methods, snow surface cleaning, construction, etc., can solve the problems of operator's strenuous effort, unable to stop the car, traffic impact, etc., and achieve the effect of convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

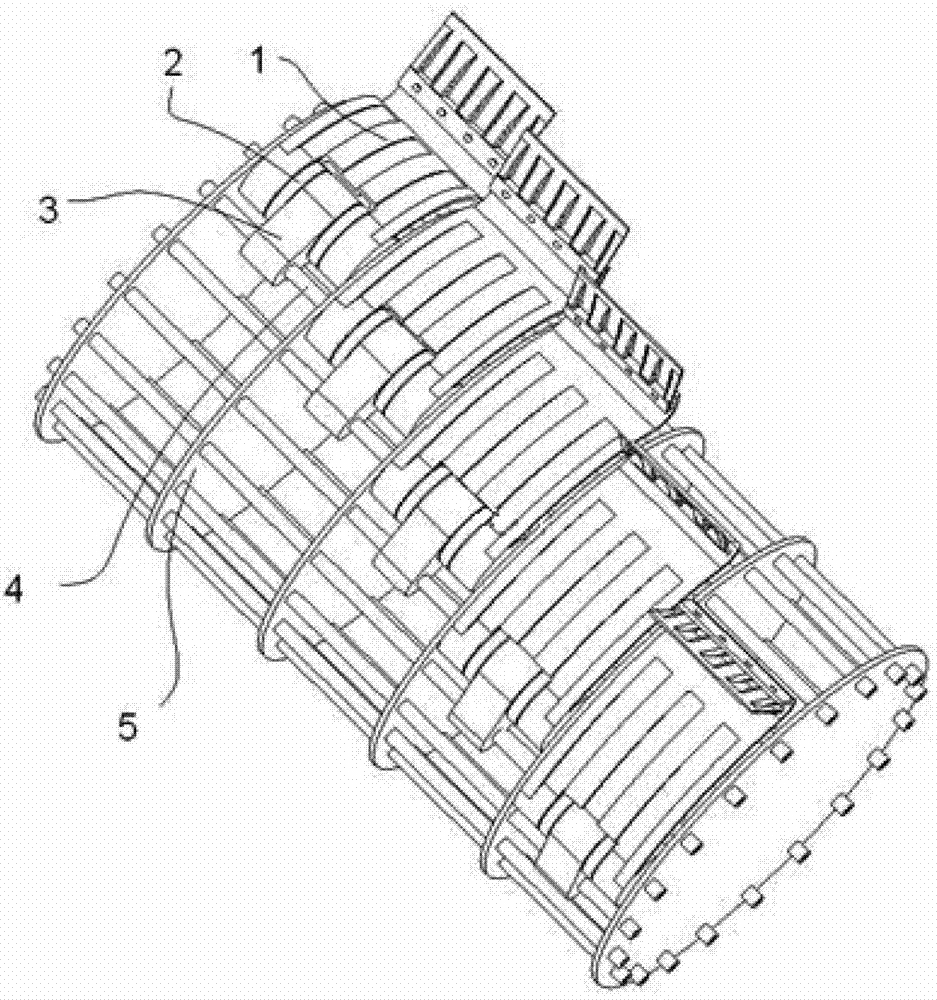

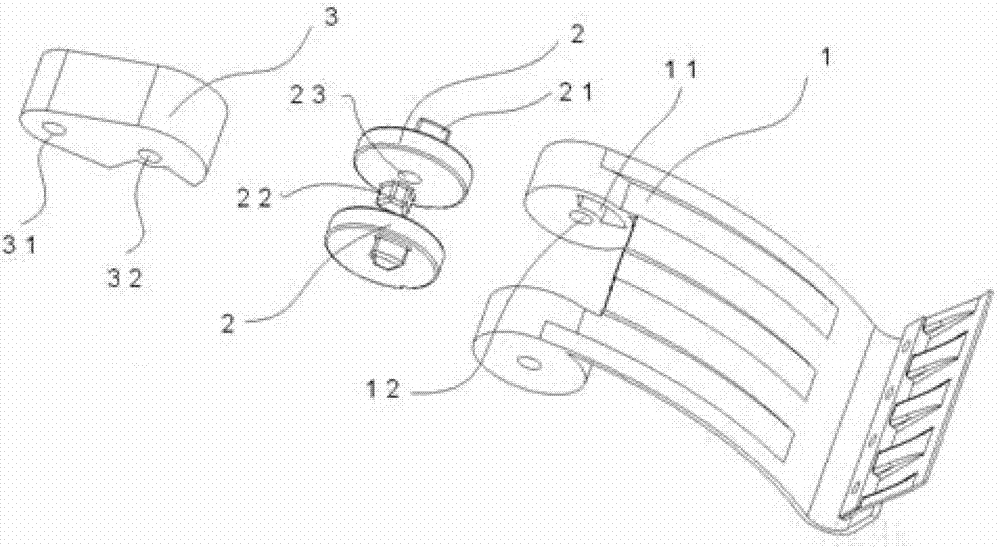

[0016] Such as Figures 1 to 3 As shown, the spiral clutch type ice cutting machine includes a roller and an ice cutting blade assembly arranged on the roller. The roller includes several roller support plates 5 arranged side by side at intervals, and two adjacent roller support plates 5 pass through The positioning shaft 4 is connected, and the ice cutting blade assembly is transferred on the positioning shaft 4. The ice cutting blade assembly is provided with a first through hole 12 through which the positioning shaft 4 passes, and the roller is provided with a limiting chisel. A limiting mechanism for the rotation angle of the ice blade assembly. The limiting mechanism includes a blade limiting seat 3 fixed on the roller and a connecting piece connecting the blade limiting seat 3 and the ice cutting blade assembly, and the side of the blade limiting seat 3 is provided with a first locking groove 33 , the connecting piece extends into the first locking groove 33 , and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com