Full-automatic water-saving drainage and irrigation seepage-proofing canal cast-in-situ forming machine

A fully automatic, forming machine technology, applied in water conservancy projects, artificial waterways, buildings, etc., can solve the problems of low strength, uneven wall thickness, high power consumption, etc., and achieve the effect of thin wall thickness, high strength, and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

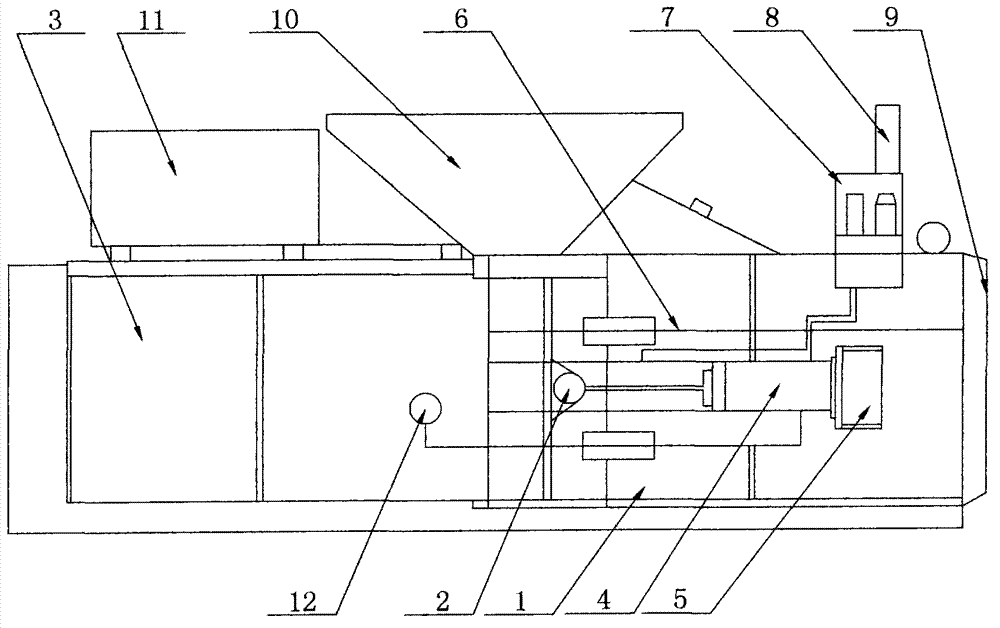

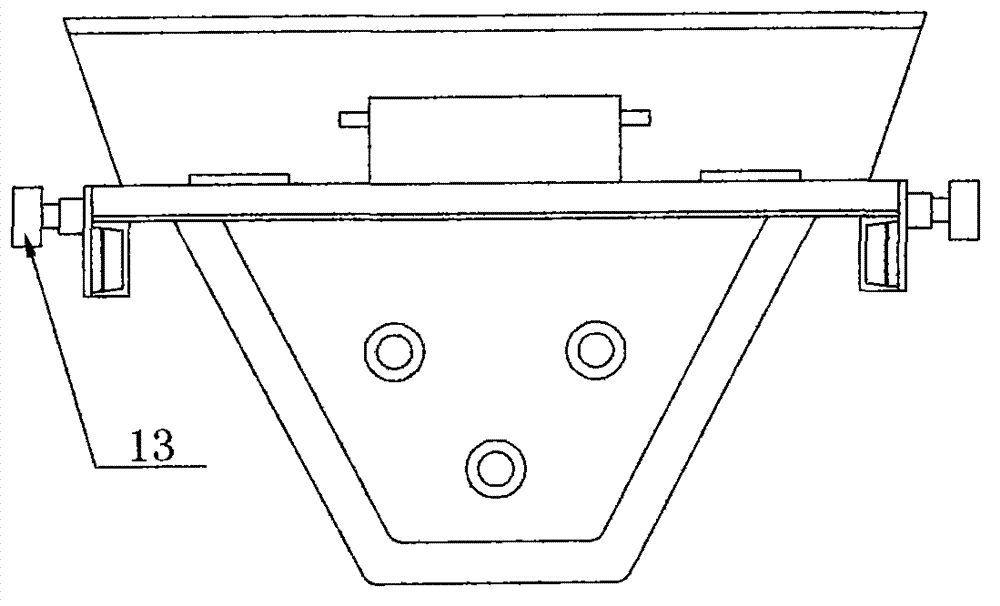

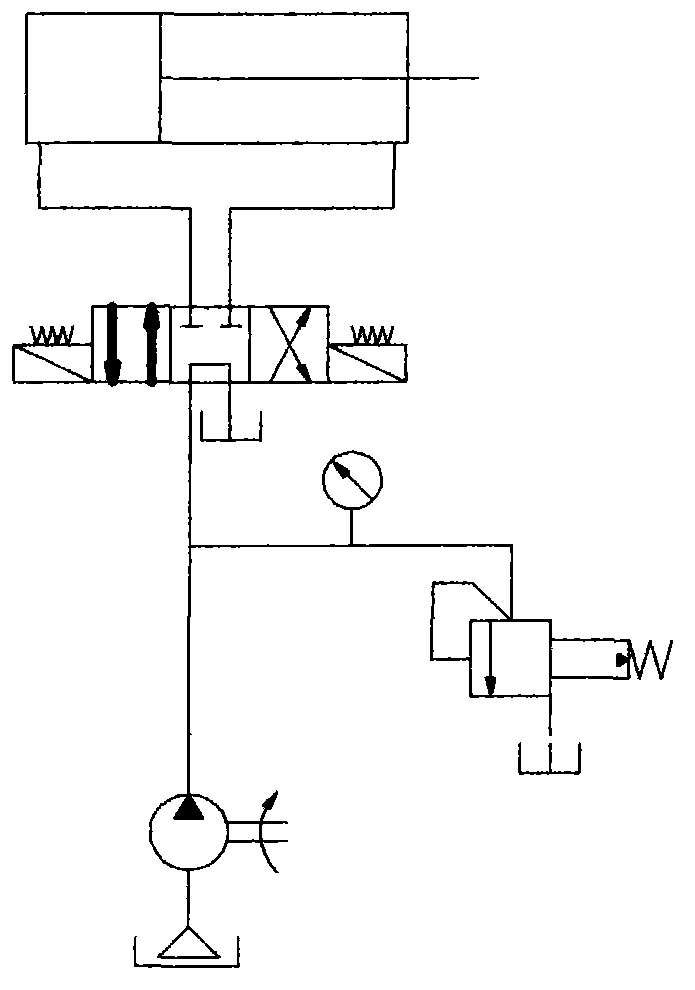

[0016] see Figure 1-Figure 4 , the specific embodiment adopts the following technical scheme: it includes a mechanical trapezoidal main body 1, a propeller 2, a trapezoidal inner forming die 3, a propulsion hydraulic cylinder 4, a cylinder support seat 5, a sliding pipe rod 6, a hydraulic assembly 7, an electrical control Cabinet 8, channel shovel 9, feed hopper 10, propeller 2 is provided at the left end of the mechanical main body 1, and the left end of the propeller 2 is provided with a trapezoidal inner forming die 3, and several sliding pipe rods 6 are arranged in the mechanical main body 1, The propulsion hydraulic cylinder 4 is connected with the propeller 2, the right end of the propulsion hydraulic cylinder 4 is provided with an oil cylinder support seat 5, the left side of the positioning plate at the rear end of the propeller 2 is provided with a feed hopper 10, and the upper end side of the mechanical main body 1 is provided with a hydraulic assembly 7, and the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com