Pile side negative friction resistance test device in frozen earth areas and application method thereof

A technology of negative friction resistance and testing equipment, which is applied in the test of basic structure, construction, basic structure engineering, etc., can solve the problems of many engineering accidents, and achieve the effect of accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

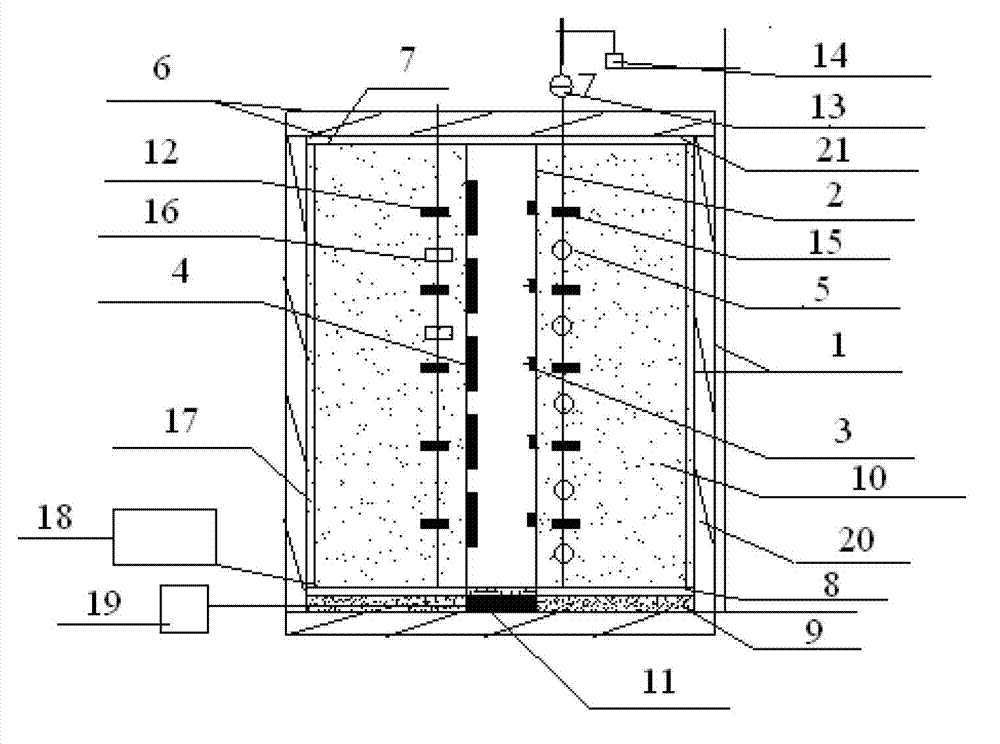

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, the pile side negative friction resistance testing device in the permafrost region of the present invention includes a hollow pile 2 and a strain gauge A3 and a strain gauge B4 arranged inside the hollow pile 2. The hollow pile 2 is arranged in a double-layer steel drum 1, and the double Inorganic thermal insulation mortar 20 is laid between the steel drums 1. The double-layer steel drum 1 is provided with a top cover 6, and a refrigeration pipe 17 is arranged along the circumference close to the inner wall of the double-layer steel drum 1. The refrigeration pipe 17 is connected with a refrigerator 18. A water supply device 11 is installed below the hollow pile 2 in the steel drum 1 and is connected to the pool 19 through pipelines. The upper and lower sides of the double-layer steel drum 1 are respectively provided with a top plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com