Embedded pipe for sampling pile tip of filling pile

A technology of pre-embedded pipes and cast-in-place piles, which is applied in the test of foundation structure, construction, foundation structure engineering, etc., can solve the problems of inability to understand the concrete and bearing layer of the pile body at the end of the pile, and inability to penetrate the length of the pile.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

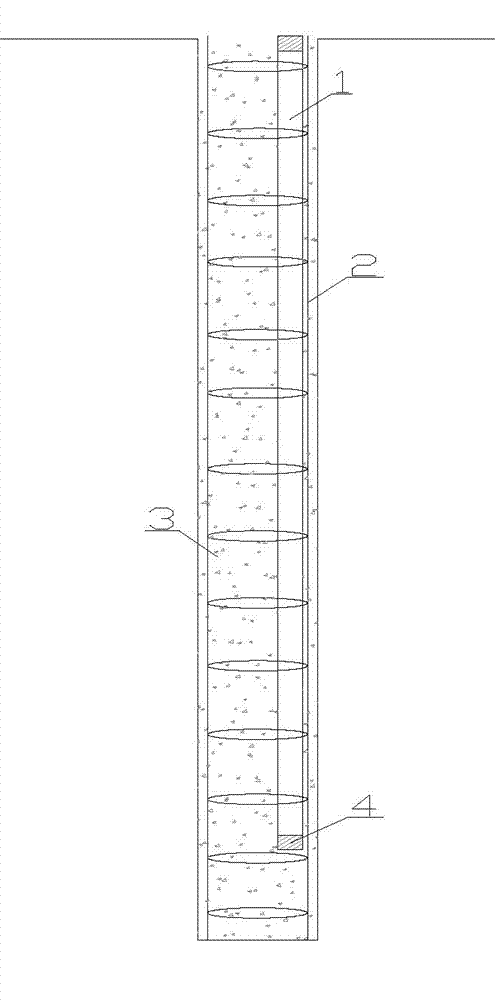

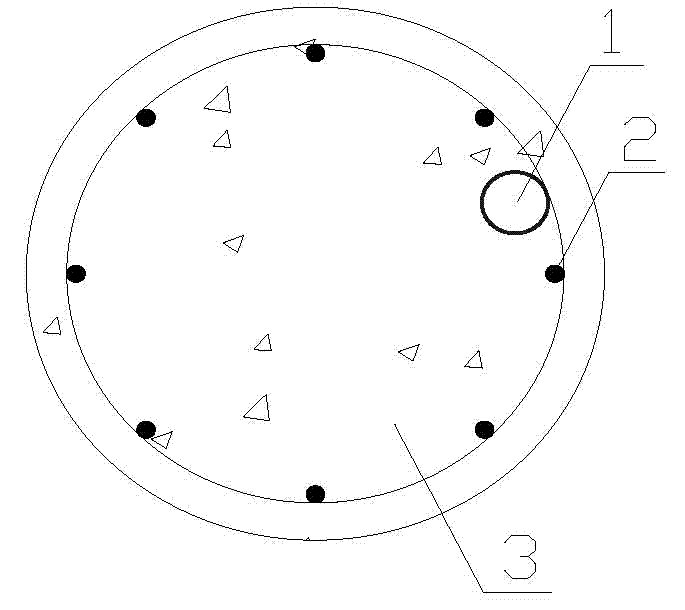

[0015] Such as figure 1 and figure 2 As shown, the pre-embedded pipe 1 is a steel pipe coaxially attached to the inner side of the reinforcement cage 2 of the cast-in-situ pile 3. The inner diameter of the steel pipe is not less than the diameter of the drill bit of the core sampling machine, and the inner diameter of the steel pipe is usually greater than 1100mm. The elevation of the top of the pre-embedded pipe 1 is the same as that of the top of the cast-in-situ pile 3, and the elevation of the bottom of the pipe is 3-5m higher than the end elevation of the cast-in-place pile 3.

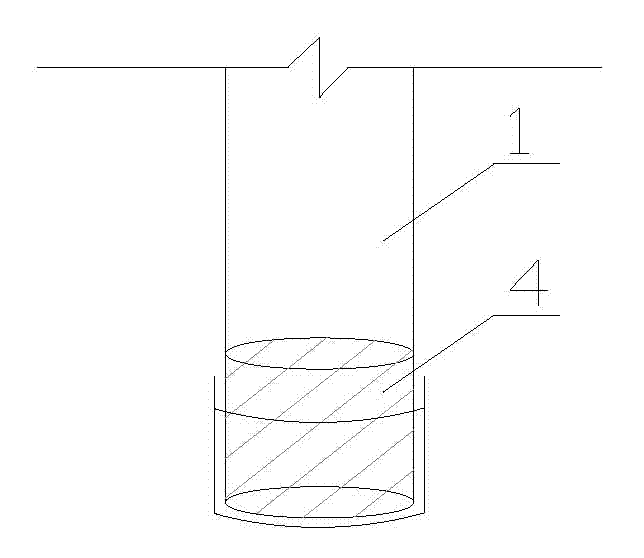

[0016] Such as image 3 As shown, the two ends of the pre-embedded pipe 1 are sealed to form a plugging head 4 to prevent concrete from entering the pipe. The end of the pre-embedded pipe 1 is sealed with wood-bonded sealant or other existing sealing methods. Blocking measures can effectively prevent concrete or grout from entering the pipe without affecting the drilling of subsequent sampling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com