Claw type generator power generation circulating device for thermal power generation

A circulation device and engine technology, which is applied in the direction of intermeshing engines, steam engine devices, machines/engines, etc., can solve the problems of difficult implementation of Stirling generators and huge steam turbine devices, and achieve low vibration and noise and uniform rotational torque , high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

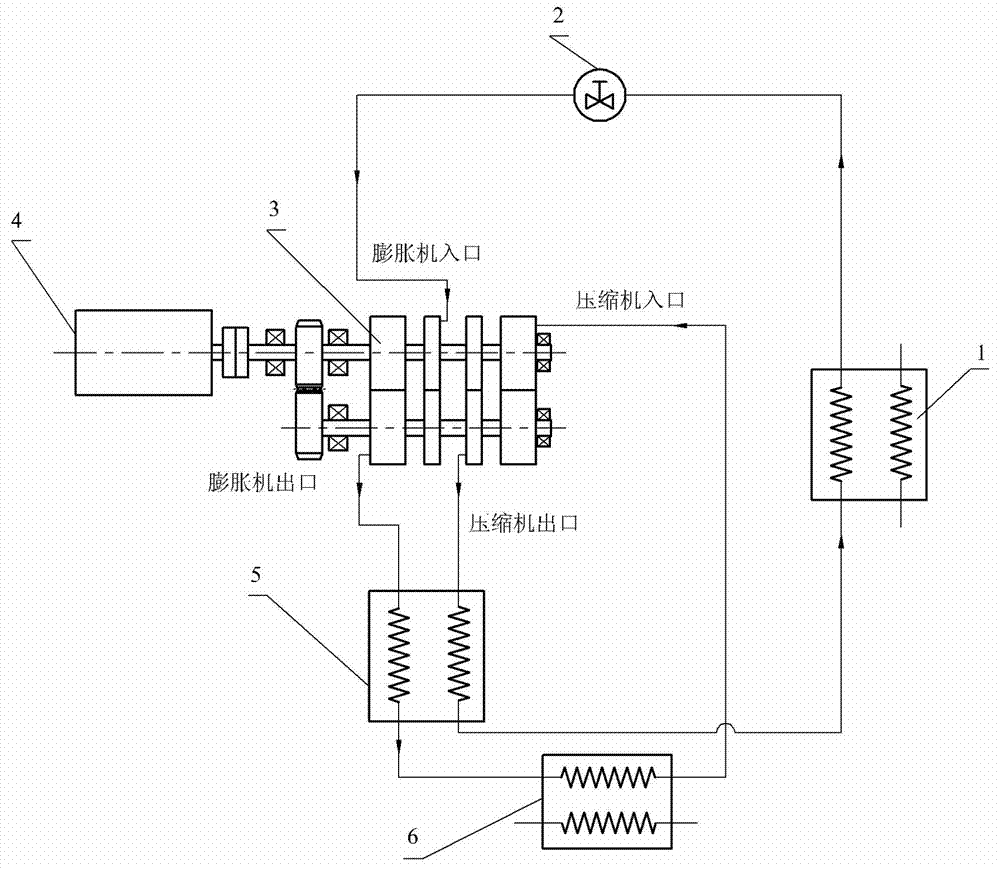

[0014] Such as figure 1 The schematic diagram of the claw engine power generation cycle device for the thermal power generation system shown includes a heater 1 , a check valve 2 , a claw compressor expander 3 , a generator 4 , a regenerator 5 and a cooler 6 . Its working process is: after the gas is compressed by the claw compressor in the claw compressor expander 3, it enters the heater 1 to absorb heat, and enters the claw expander in the claw compressor expander 3 to expand and perform external work. The expanded gas enters the regenerator 5 for heat release, the temperature of the gas decreases, and then enters the cooler 6 to be further cooled, and the cooled gas enters the claw compressor in the claw compressor expander 3 for compression; The compressed gas enters the regenerator 5 to absorb the heat of the expanded gas, and then enters the heater 1 to absorb heat so that the temperature rises again, and the gas after absorbing heat enters the claw compressor expander 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap