Forging hydraulic press pump accumulator transmission system and pressure transformation method thereof

A transmission system and accumulator technology, applied in the field of forging hydraulic presses, can solve the problems of large footprint, high energy consumption, and large capital investment, and achieve the effects of small footprint, low operating cost, and low capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

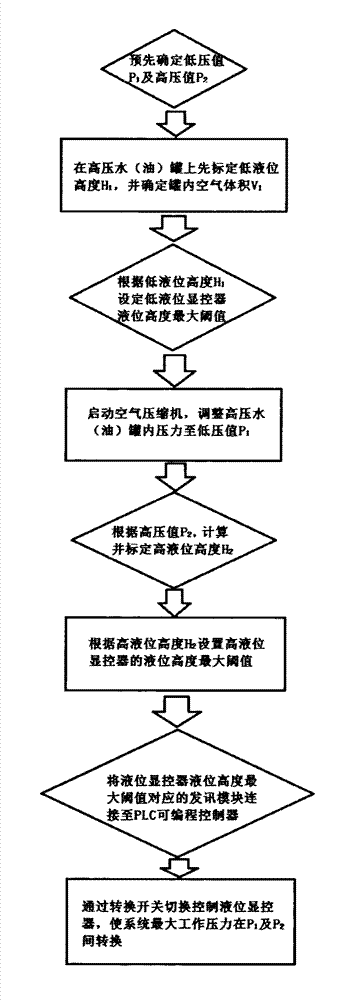

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0031] refer to figure 1 , a forging hydraulic machine pump accumulator transmission system, comprising: a group of accumulators composed of several groups of high-pressure liquid tanks and high-pressure gas tanks, the high-pressure liquid tanks are connected to a high-pressure pump, and the high-pressure gas tanks are connected to an air compressor, It also includes a high liquid level controller and a low liquid level controller arranged on the high-pressure liquid tank, and the high liquid level controller and the low liquid level controller are equipped with a communication module with a communication interface to communicate with the PLC Connect to realize the control of the liquid level in the high-pressure liquid tank.

[0032] The trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com