Gas hydrate pipeline conveying method and gas hydrate pipeline conveying device

A technology of gas hydrates and hydrates, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., to achieve the effects of improving safety and economy, preventing deposition, and enhancing heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The content of the present invention will be further described in detail below with reference to the drawings and specific implementations:

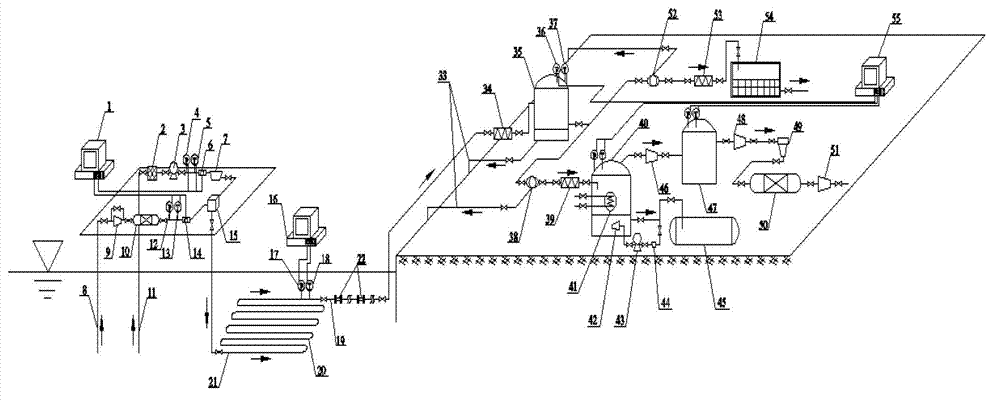

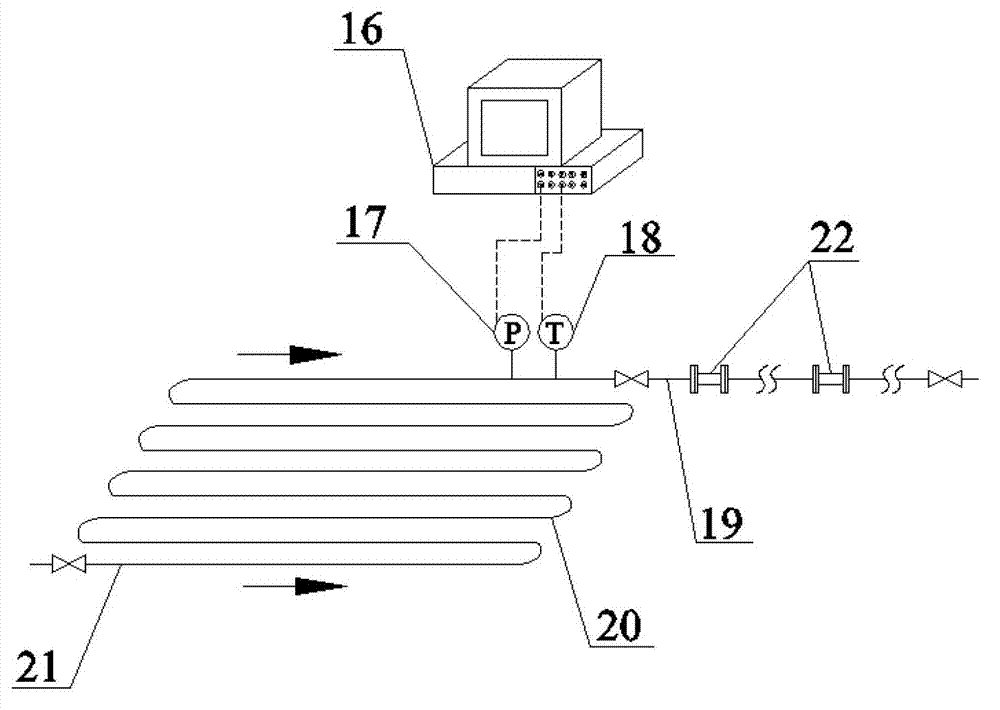

[0035] The present invention is a gas hydrate pipeline transportation method and equipment, such as figure 1 As shown, it includes three parts: gas gathering unit, hydrate generation and transportation unit, and hydrate separation and decomposition unit.

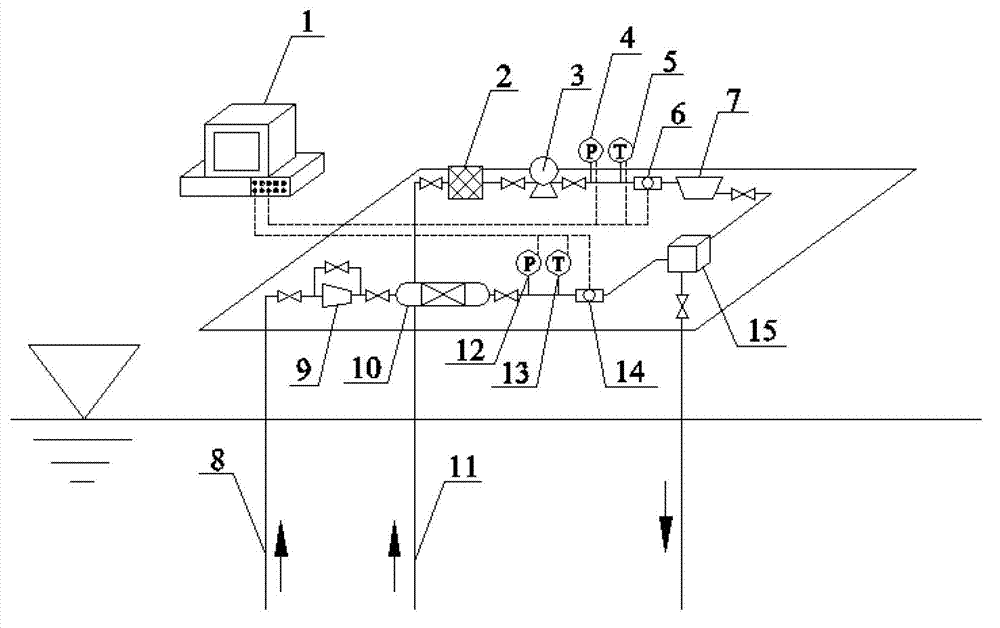

[0036] Regarding the gas gathering unit, such as figure 2 , Including computer data acquisition device 1, filter 2, delivery pump 3, pressure gauge 4, thermometer 5, flow meter 6, dosing port 7, natural gas inlet pipeline 8, compressor 9, pretreatment device 10, sea water inlet pipeline 11 , Pressure agent 12, temperature agent 13, flow meter 14 and gas-liquid mixer 15, etc.; natural gas is extracted from the submarine gas field by the offshore drilling platform and transported to the pretreatment unit 10 through the compressor 9 to perform preliminary purification of the natural ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com