Scanning electrochemical microscope electrolytic cell for plate-shaped load sample corrosion research and application thereof

A technology of scanning electrochemistry and corrosion research, applied in the field of electrochemical electrolytic cells, can solve problems such as complex structures and unsuitable electrolytic cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

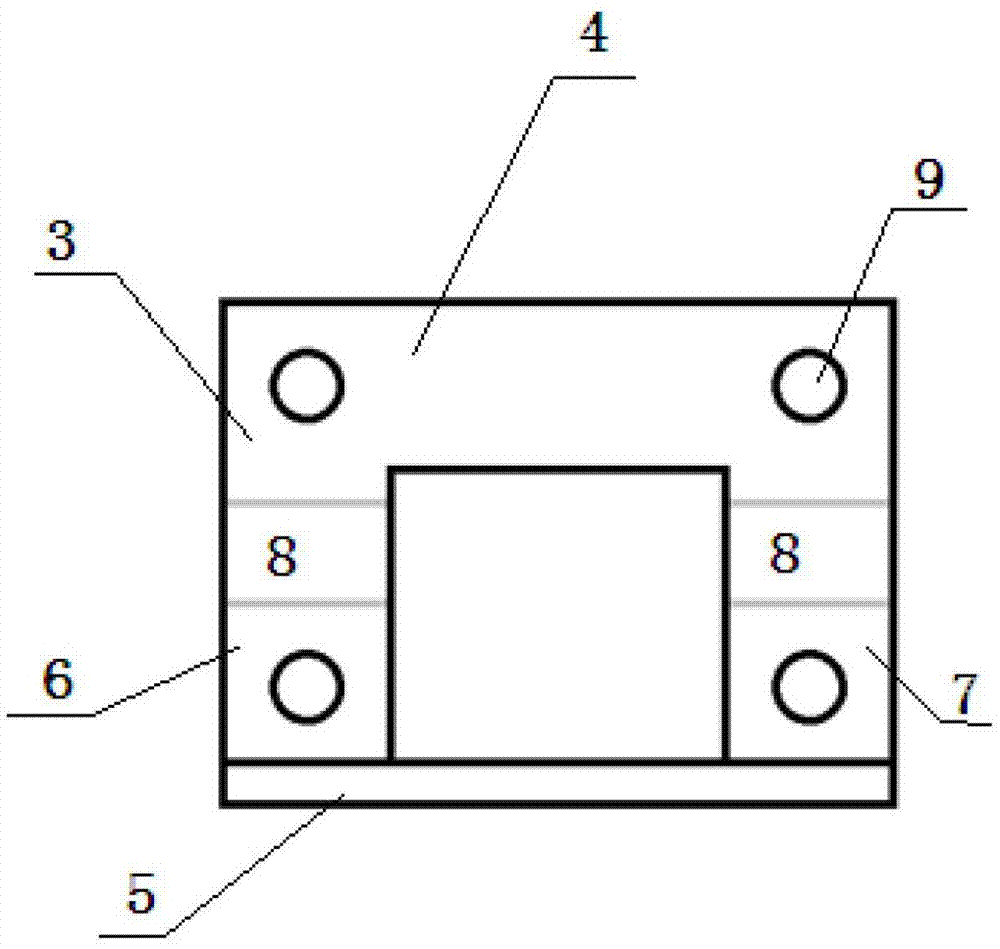

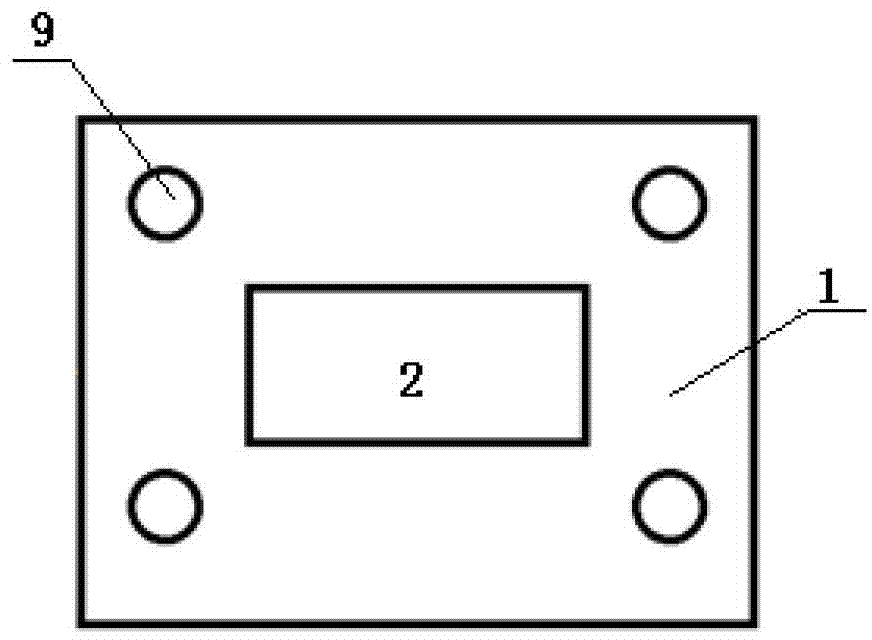

[0031] Such as Figure 1-2 shown.

[0032] A scanning electrochemical microscope electrolytic cell used for corrosion research of plate samples, comprising an upper structure 3 and a lower structure 1 surrounding an electrolytic cell chamber: a groove 2 is arranged in the center of the lower structure 1, and the upper structure 3 includes a rectangular frame 4, the front side wall 5 in the rectangular frame 4 is a transparent material, and the left side wall 6 and the right side wall 7 in the rectangular frame 4 are respectively provided with grooves 8 communicating with the outside world and the electrolytic cell; A gasket is provided between the upper structure 3 and the lower structure 1, and the shape of the gasket is adapted to the shape of the cross section of the upper structure 3; the upper structure 3, the gasket and the lower structure 1 are in Tight connection under the action of external force.

[0033] The fixing bolts 9 tightly connect and fix the superstructur...

Embodiment 2

[0038] A method utilizing the electrolytic cell described in embodiment 1 in conjunction with the scanning electrochemical microscope instrument to study the corrosion of 304 stainless steel specimens of plate load comprises the following steps:

[0039] (1) Prepare the 304 stainless steel sample: process the 304 stainless steel sample into a plate-shaped sample, and the gauge section size of the plate-shaped sample matches the groove size of the superstructure, for standby;

[0040](2) Install the electrolytic cell, plate sample, reference electrode and auxiliary electrode: set the two ends of the gauge section of the plate sample on the grooves on the left and right walls of the rectangular frame Inside, use fixing bolts to fix and seal the upper structure, sealing gasket and lower structure; install and fix the reference electrode and auxiliary electrode above the plate sample; the plate sample is the working electrode; The plate-shaped sample gauge section inside the elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com