Conduction cooling device for high-temperature superconducting magnet

A high-temperature superconducting and magnet technology, which is applied in the direction of superconducting magnets/coils, magnetic objects, electrical components, etc., can solve the problems of large steady-state temperature gradient and slow cooling speed, so as to reduce the temperature gradient, reduce intrusion, reduce Effect of eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

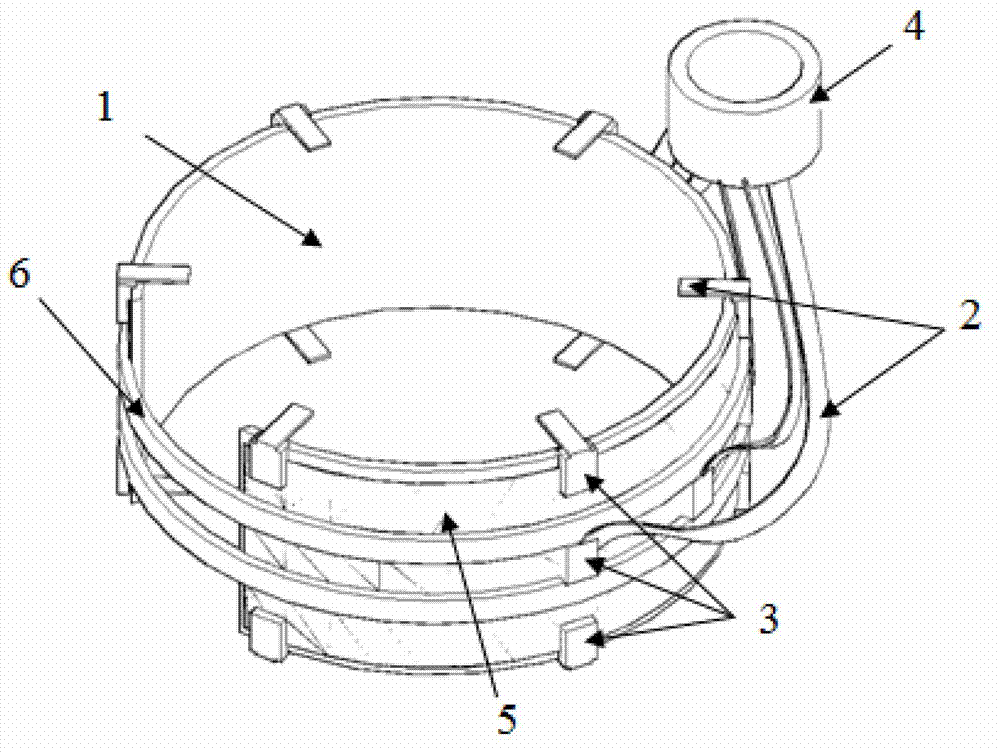

[0021] The present invention will be further explained below in conjunction with the drawings: figure 1 The high-temperature superconducting magnet conduction cooling device shown in the figure includes: a cylindrical cold conduction plate with an arc-shaped cross section, a conduction cold copper strip 2, a cold-head connecting flange 4, an anti-radiation layer 5, and an annular bracket 6. At least one cold conducting copper strip 2 is fixed at both axial ends and the middle of the cold conducting plate 1, the other end of the conducting cold copper belt 2 is fixed to the cold head connecting flange 4, and the outer surface of the cold conducting plate 1 Covering the anti-radiation layer 5, the annular bracket 6 is fixed on the outer side of the cold conducting plate for shaping the conducting cold device and improving the strength of the entire cold conducting device structure.

[0022] The arc-shaped cold conducting plate is made of high thermal conductivity materials, such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap