In-wheel motor driving device

A hub motor and driving device technology, which is applied in the direction of electromechanical devices, electrical devices, power devices, etc., can solve the problem of increased load under the spring, and achieve the effects of reducing pulling resistance, high versatility, and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, embodiments of the present invention will be described based on the drawings.

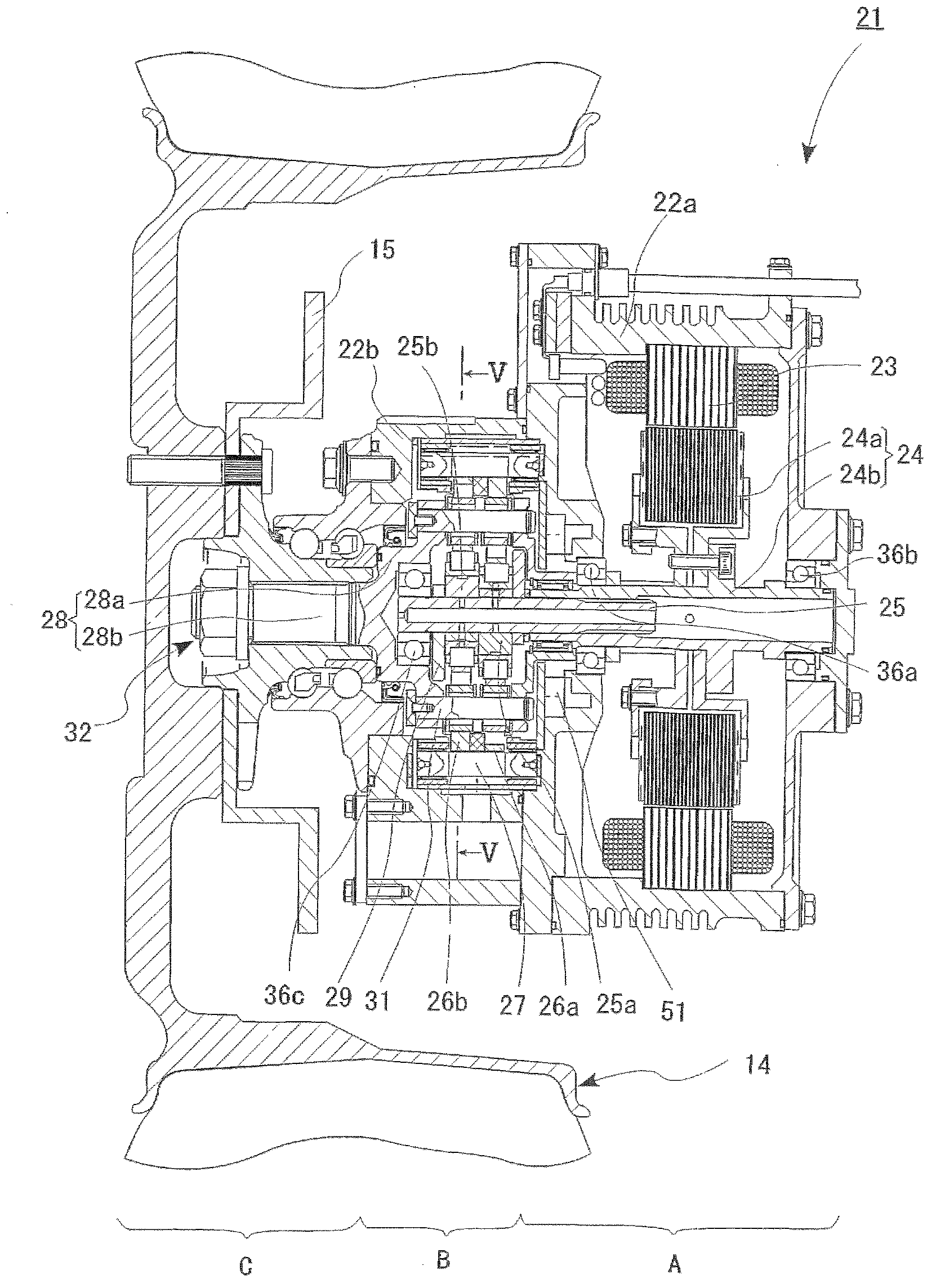

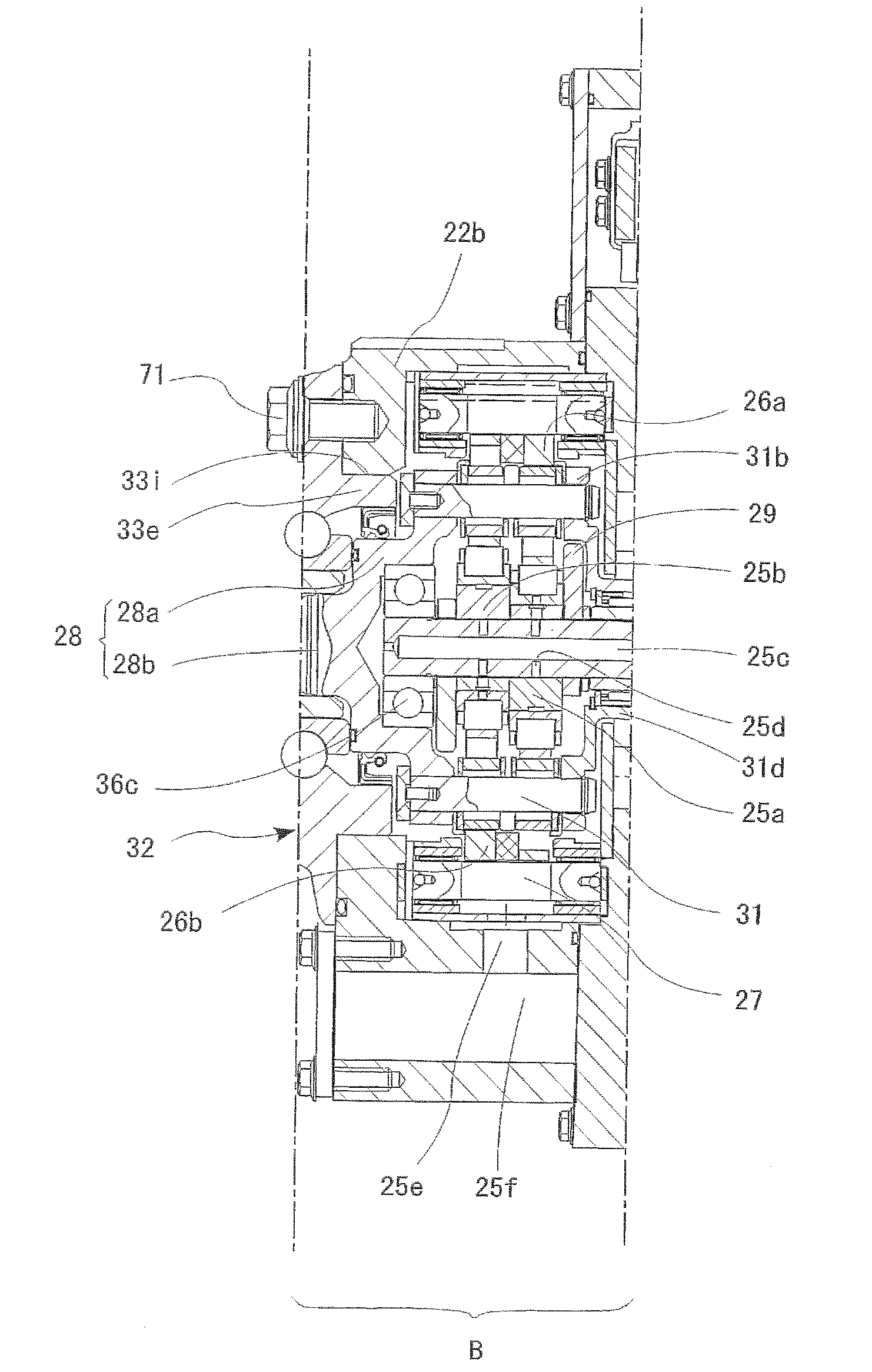

[0054] First, if figure 1 As shown, the in-wheel motor driving device 21 includes: a motor unit A that generates driving force, a deceleration unit B that decelerates the rotation of the motor unit A and outputs it, and a wheel hub bearing unit C that transmits the output from the deceleration unit B to the drive wheel 14. . Such as Figure 9 As shown, it is installed in the wheel housing 12a of the chassis 12.

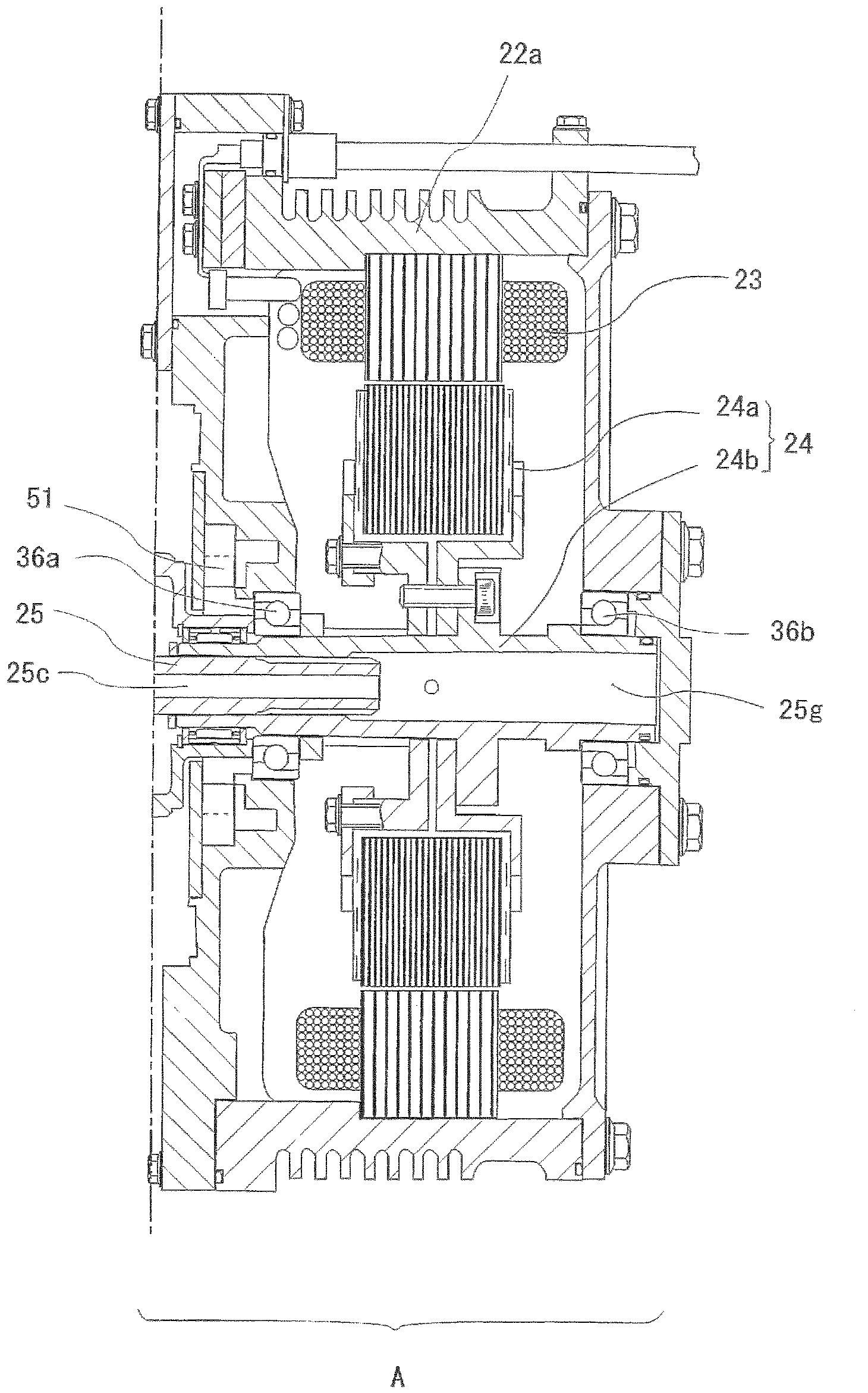

[0055] Such as figure 2As shown, the motor part A is a radial gap motor, and includes a stator 23 fixed to a casing 22a, a rotor 24 disposed at a position opposite to the inner side of the stator 23 with a gap in the radial direction, and fixedly connected to the inner side of the rotor 24 and connected to the inner side of the rotor 24. The rotor 24 is a motor-side rotating member 25 that integrally rotates. The rotor 24 has a flange-shaped rotor 24a and a cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com