Polymeric blends useful in ballistic applications

A technology of bulletproof fabrics and thermoplastic polymers, applied to the structure of fabrics, protective equipment, armor plates, etc., can solve the problems of not solving heat resistance, not involving the advantages of thermoplastic resin blends, not suitable for exposure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

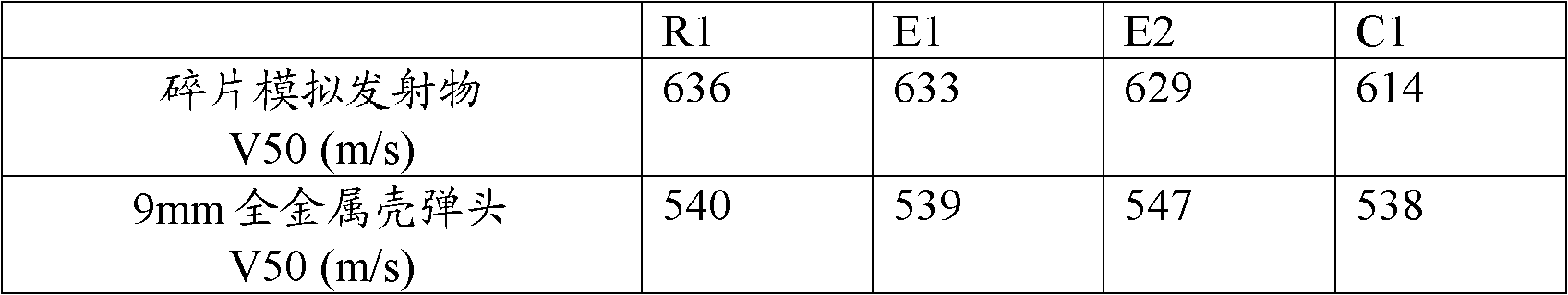

[0108] Reference Example R1 :

[0109] Pre-impregnated with 400g / m by the following method 2 area weight and is composed of fibers with a decitex linear quality of 3140 and can be trademarked 129 Commercially available polyparaphenylene terephthalamide plain weave fabric from DuPont de Nemours, USA: according to military standard MIL-DTL-62474F, it is compared with 2 B-stepped PVB / phenolic resin films of areal density were calendered together to obtain a pre-impregnated parylene terephthalamide fabric.

[0110] Eighteen layers of the polyparaphenylene terephthalamide pre-impregnated fabric obtained by the method described above were stacked and compression molded in a parallel plate automatic press using a pressure of 10 bar and a temperature of 165° C. for 15 minutes.

[0111] The resulting 18-layer stack was removed from the heat press and allowed to cool to room temperature. The 18-layer composite panels obtained by the above method were conditioned at 25°C and 50% rela...

Embodiment E2

[0122] The two ingredients used for the umbrella bag are:

[0123] 1. Can trademark 129 from DuPont de Nemours, the commercially available polyparaphenylene terephthalamide plain weave fabric of USA, it has 400g / m 2 of areal weight and consist of fibers with a decitex linear quality of 3140.

[0124] 2. A cast extruded sheet of a thermoplastic composition having a thickness of 50 μm and a melting point of 178° C. and consisting of 60% by weight of nylon 12 and 40% by weight of zinc ionomer, based on the weight of the thermoplastic composition, said nylon 12 has a melting point of 180°C and is commercially available from Arkema under the trademark Rilsan AESNO; the zinc ionomer has a melting point of 95°C, has a neutralization percentage of 60% and comprises ethylene (83% by weight), methacrylic acid (11 % by weight) and maleic anhydride (6% by weight).

[0125] The umbrella case was made of 18 layers of parylene terephthalamide fabric combined with 18 layers of cast extrud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com