Vacuum pump

一种真空泵、泵部的技术,应用在泵、泵装置、泵元件等方向,能够解决没有缓和负荷等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

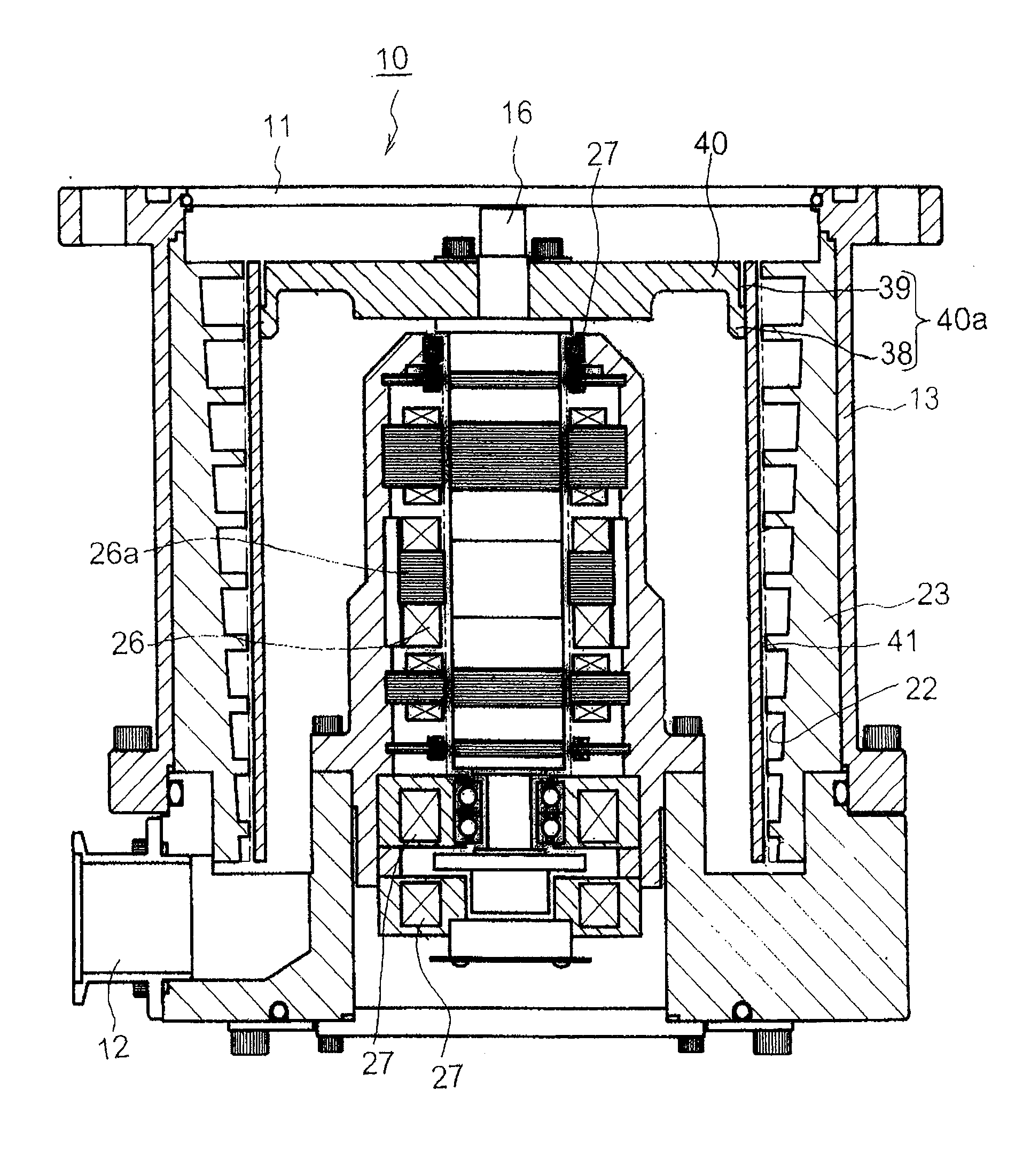

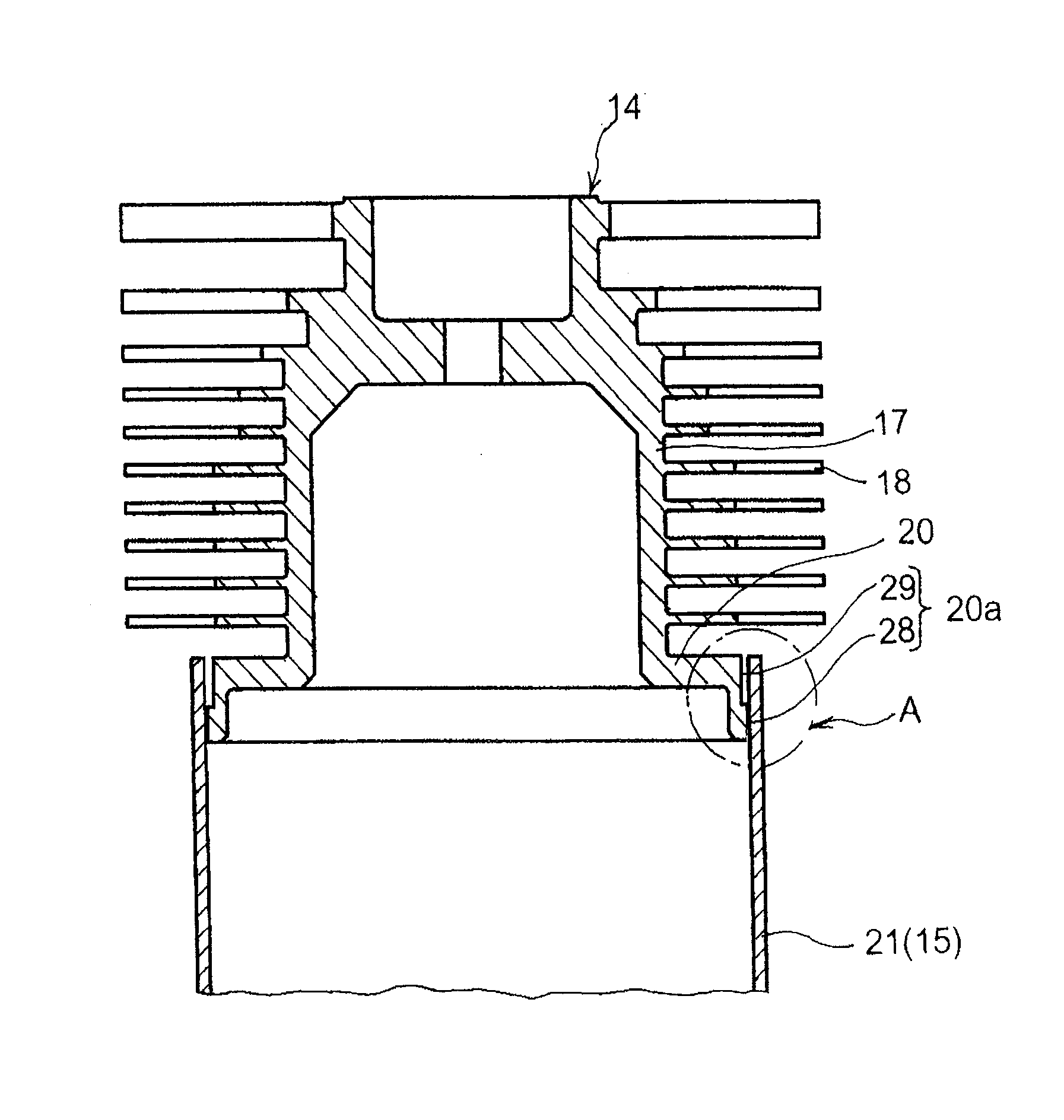

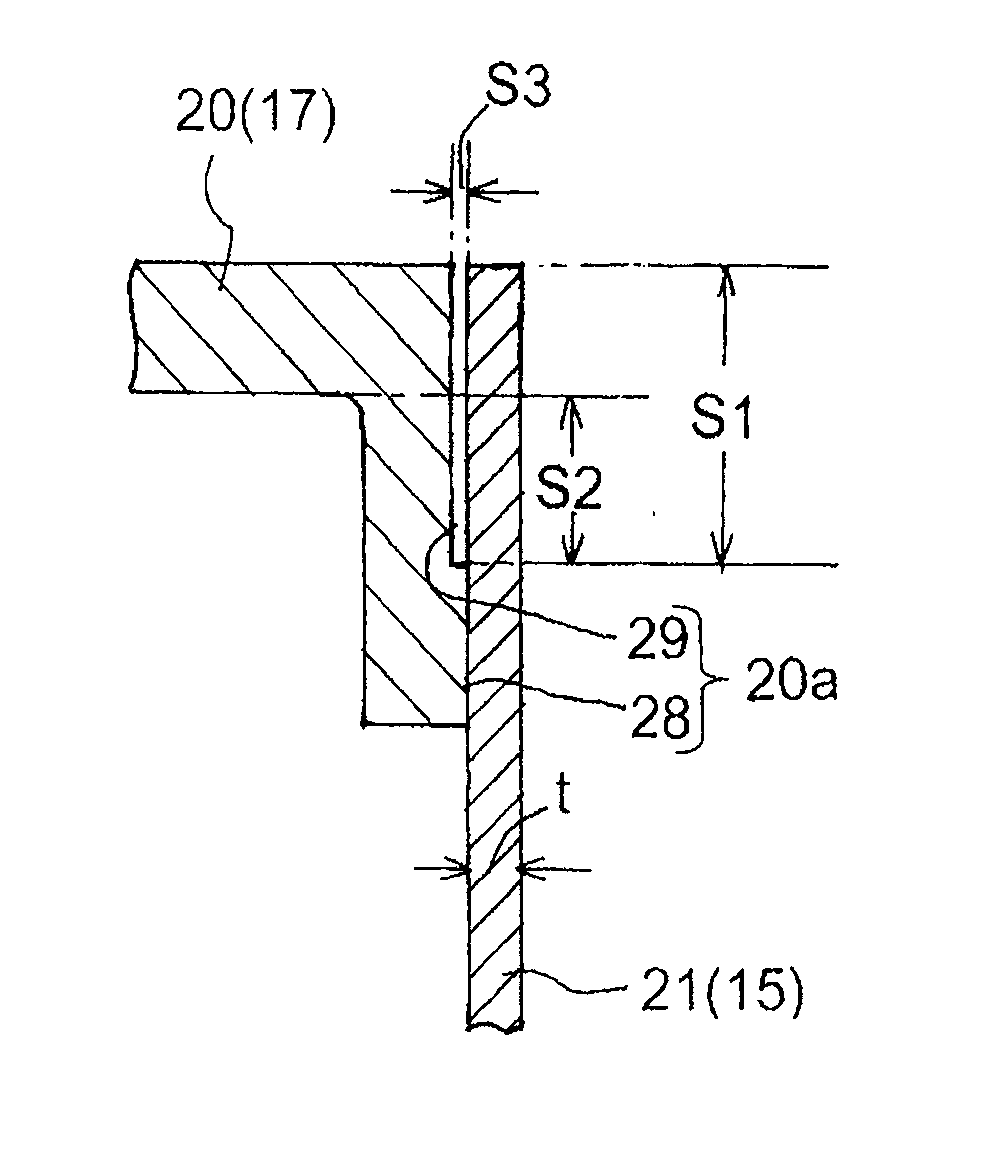

[0044] Hereinafter, preferred embodiments of the compound vacuum pump of the present invention will be described with reference to the drawings. 1 and 2 are diagrams showing a composite vacuum pump related to the present invention, FIG. 1 is a longitudinal sectional view thereof, and FIG. 2 shows a joint structure of a rotor of a turbomolecular pump part of the pump and a cylindrical rotor of a screw groove pump part. 3 is an enlarged sectional view of A portion in FIG. 2 , and FIG. 4 is an exploded longitudinal sectional view showing the joining portion of the rotor of the turbomolecular pump unit shown in FIG. 2 and the cylindrical rotor of the screw groove pump unit.

[0045] In this figure, a composite vacuum pump 10 includes a casing 13 having an air intake port 11 and an exhaust port 12 . Inside the casing 13, a turbomolecular pump part 14 is provided on the upper part, and a cylindrical thread groove pump part 15 is provided below it, and a structure passing through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com