Mower and butt-joint charging system

A technology for charging systems and lawn mowers, applied to harvesters, circuits, connections, etc., can solve problems such as poor contact of charging terminals, wet charging terminals, corrosion, etc., and achieve the effect of avoiding poor contact and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

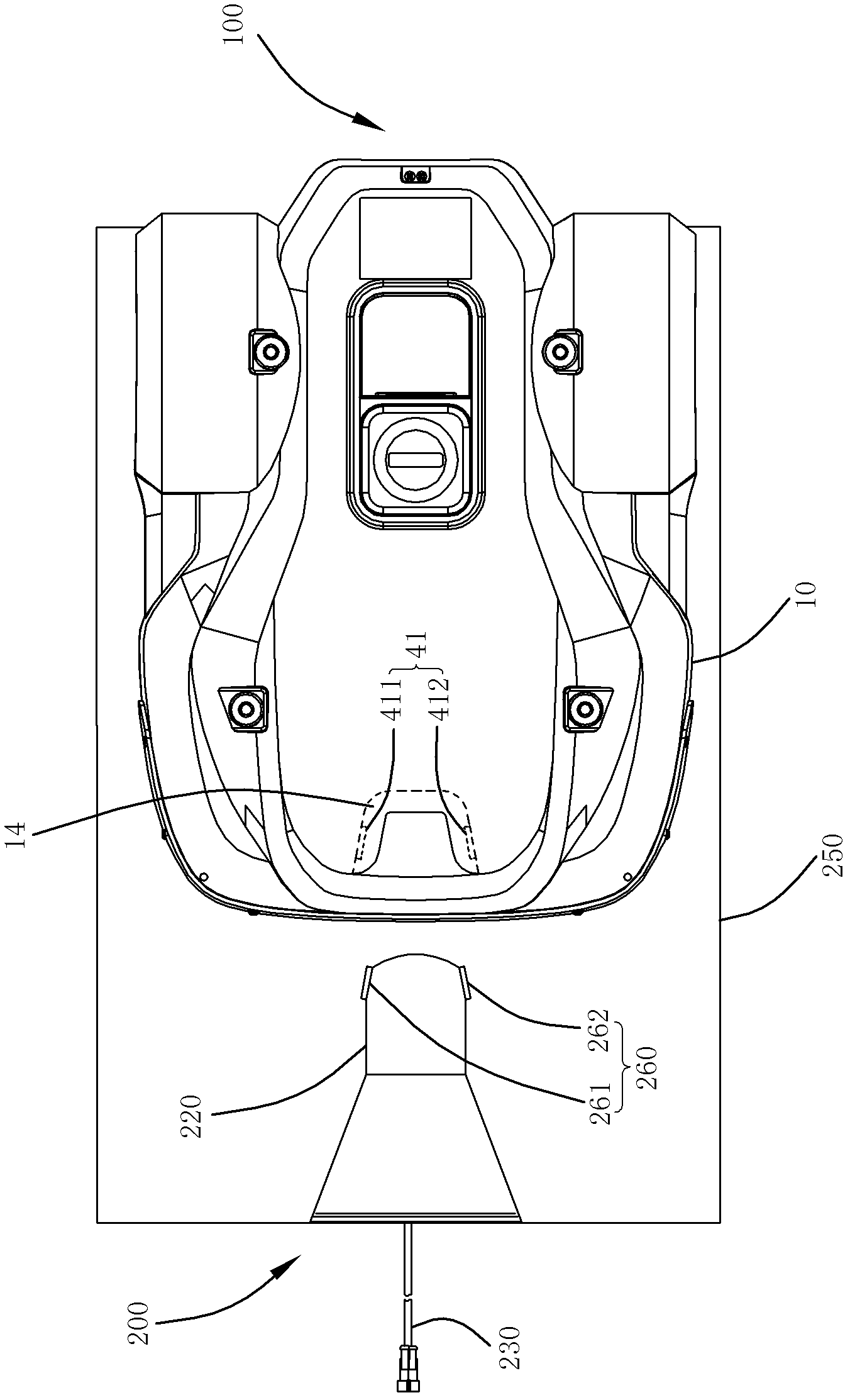

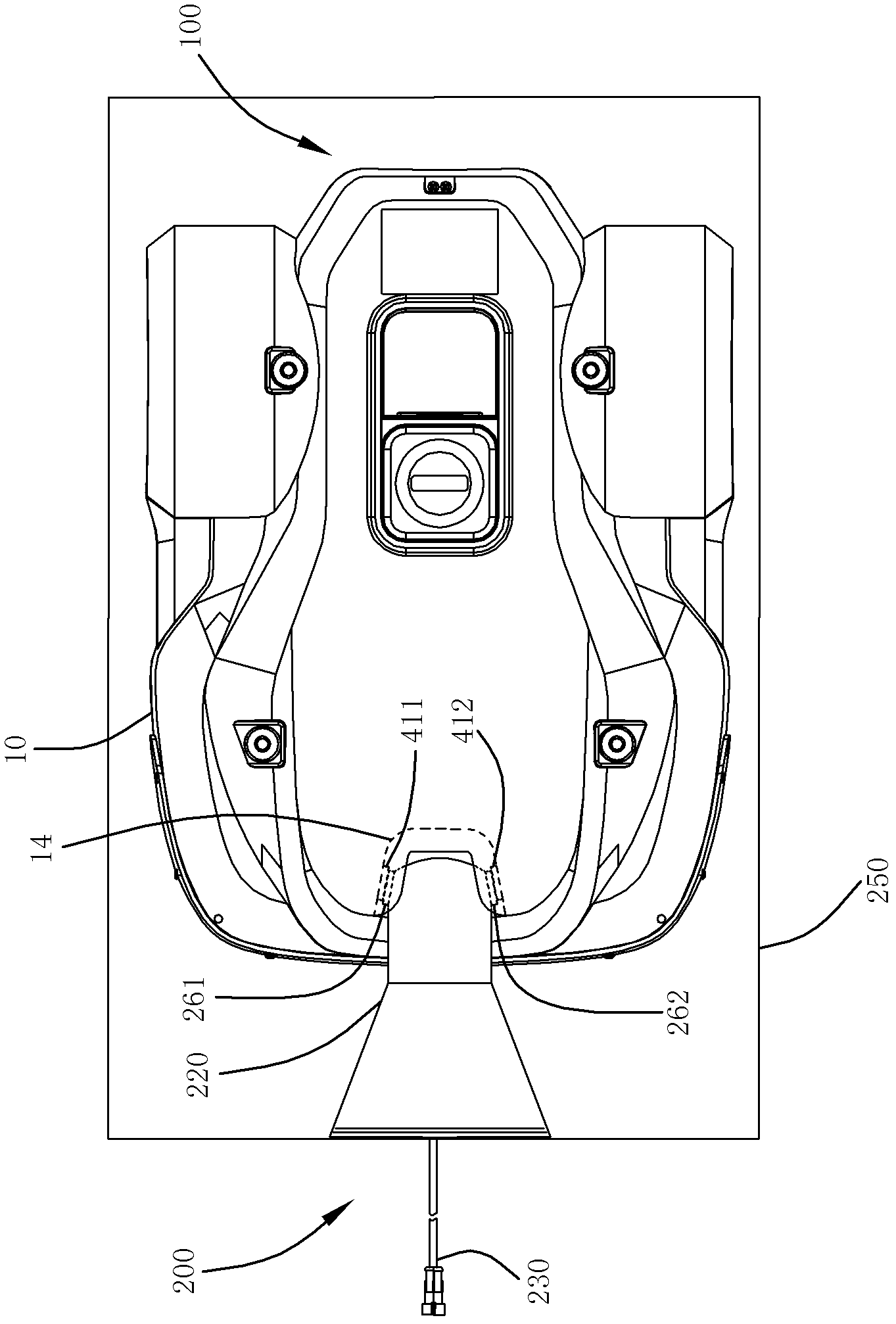

[0111]In other embodiments, the dustproof plate can also be made of insulating material, instead of being a part of the first terminal 411 or the second terminal 412 , it is only used to partially or completely block the opening of the charging slot 14 .

other Embodiment approach

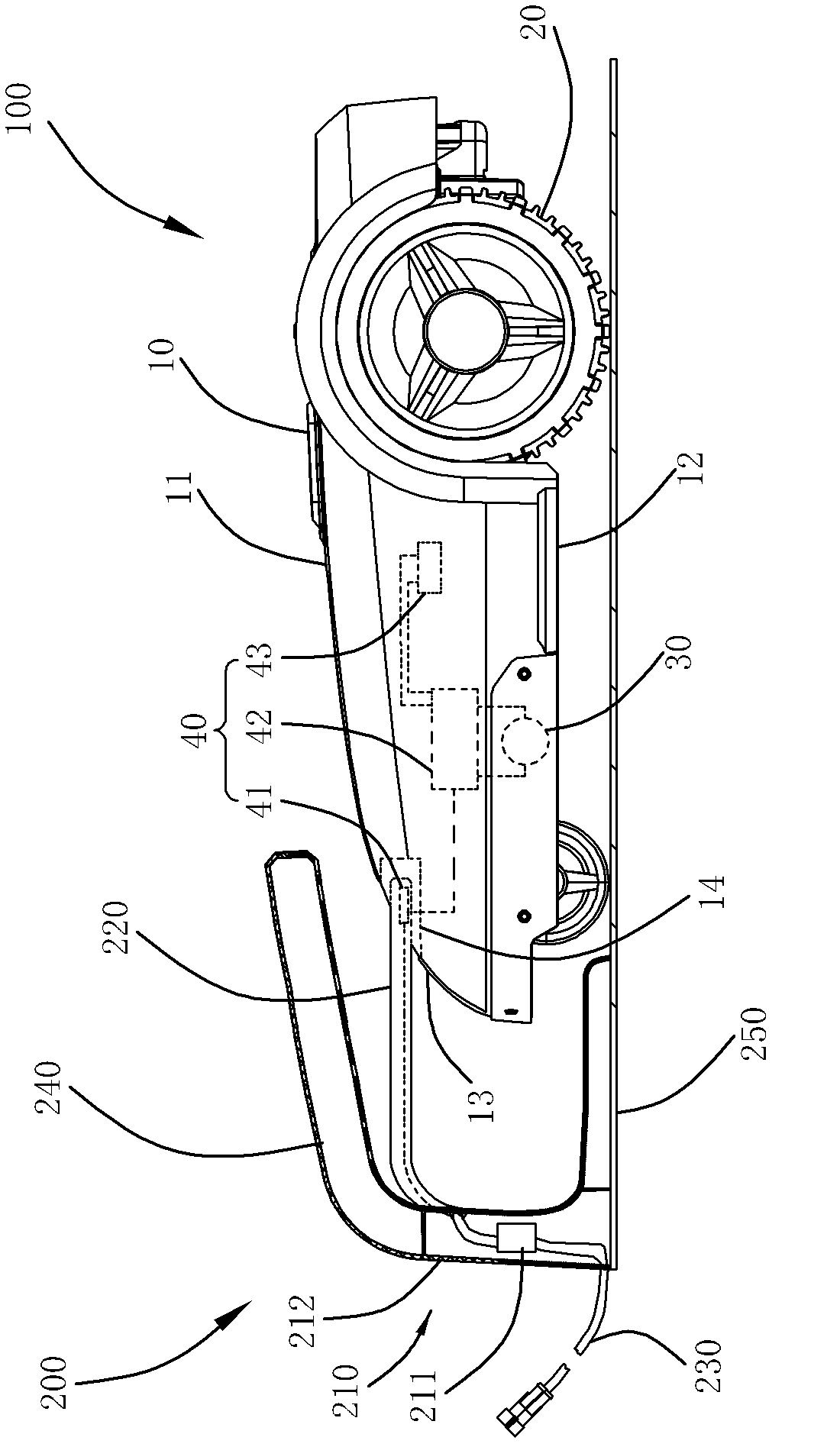

[0112] In other embodiments, the power terminal 260 can also movably protrude from the base 210 . When the automatic lawn mower 100 is not connected to the charging station 200 for charging, the power terminal 260 is hidden inside the base 210; when the automatic lawn mower 100 returns to the charging station 200, the automatic lawn mower 100 first triggers the A trigger (not shown), the trigger guides the power terminal 260 from the inside of the base 210 to the outside of the base 210, so that the power terminal 260 stretches into the charging slot 14 of the automatic lawn mower 100 and is connected to the charging terminal. 41 butt. In this way, when the charging station 200 does not need to charge the robotic lawn mower 100, the power terminal 260 will not be exposed to the outside, and it is not easy to be wet by rain and be corroded.

[0113] Please refer to Figure 16 and Figure 17 , In the seventh preferred embodiment of the docking charging system of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com