Laser welding clamp and protecting device for titanium alloy thin-walled workpiece in shape of complex space

A laser welding jig and space shape technology, applied in laser welding equipment, auxiliary equipment, welding equipment, etc., can solve the problems of difficult realization of gas protection devices, large changes in weld space curvature, poor protection effect, etc., to achieve protection Good effect, simple preparation and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0031] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0032] In order to clearly express the structure and method of use of the present invention, a component with a more complex spatial structure is used as the welded part.

[0033] (1) Overall tooling composition

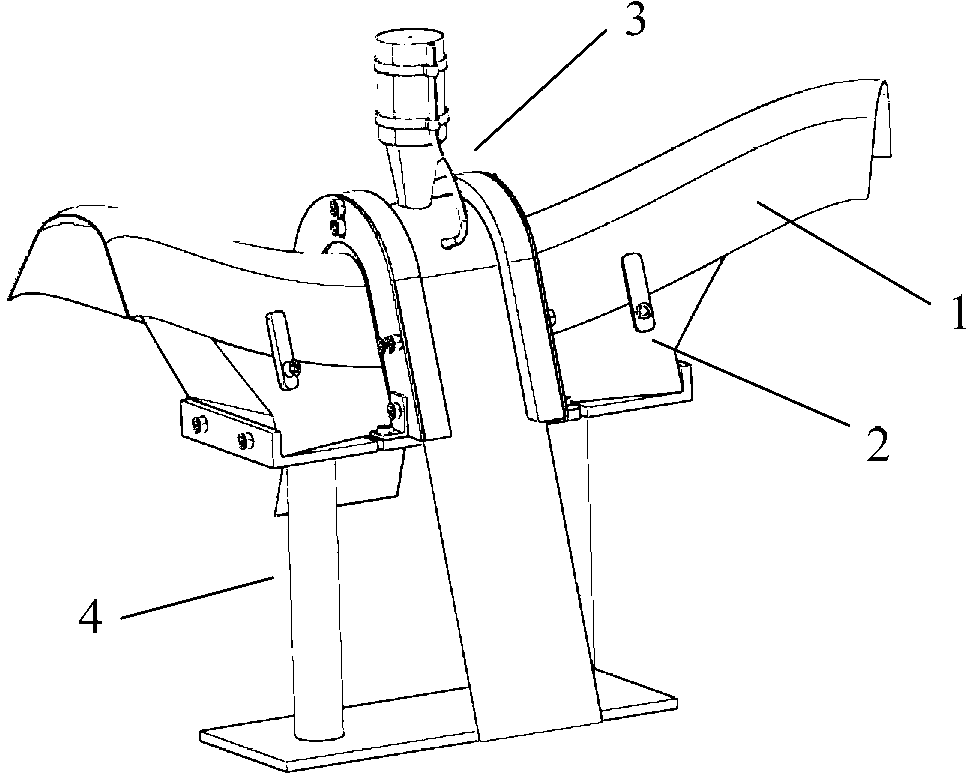

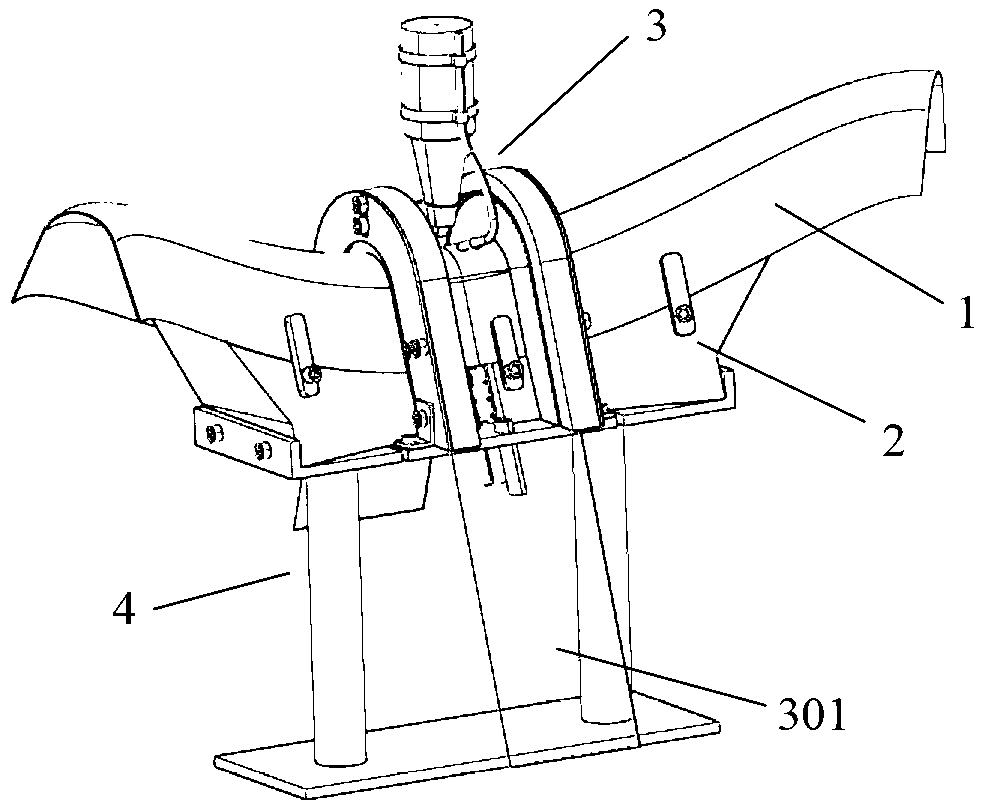

[0034] Refer to figure 1 versus figure 2 , The main body of the clamp and protection tooling invention includes clamp 2, gas protection device 3 and lower support base 4. In order to make the expression more clear, take the clamping and protection of the weldment 1 as an example.

[0035] (2) Description of sample weldment

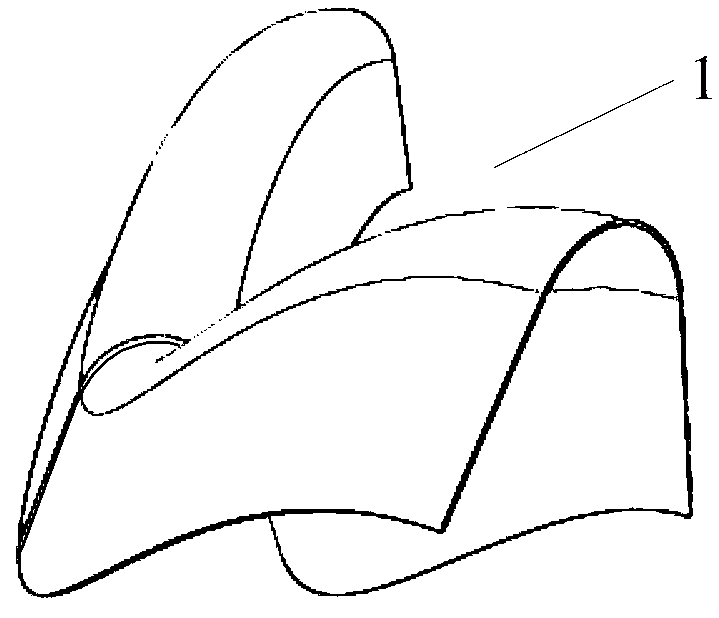

[0036] Refer to image 3 As shown in Figure 4, the weldment 1 is formed by connecting the first weldment 101 and the second weldment 102 through a weld 103, and the first weldment 101 and the second weldment 102 are complex-shaped thin-walled parts .

[0037] The complex shape and poor rigidity of the parts to be welded lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com