Mould for optic lens

A technology of optical lenses and molds, which is applied to optical components, household appliances, and other household appliances. It can solve the problems of easy petrification of diamond knives, poor liquid circulation, and increased defective rate, so as to improve deformation, increase yield, and The effect of force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

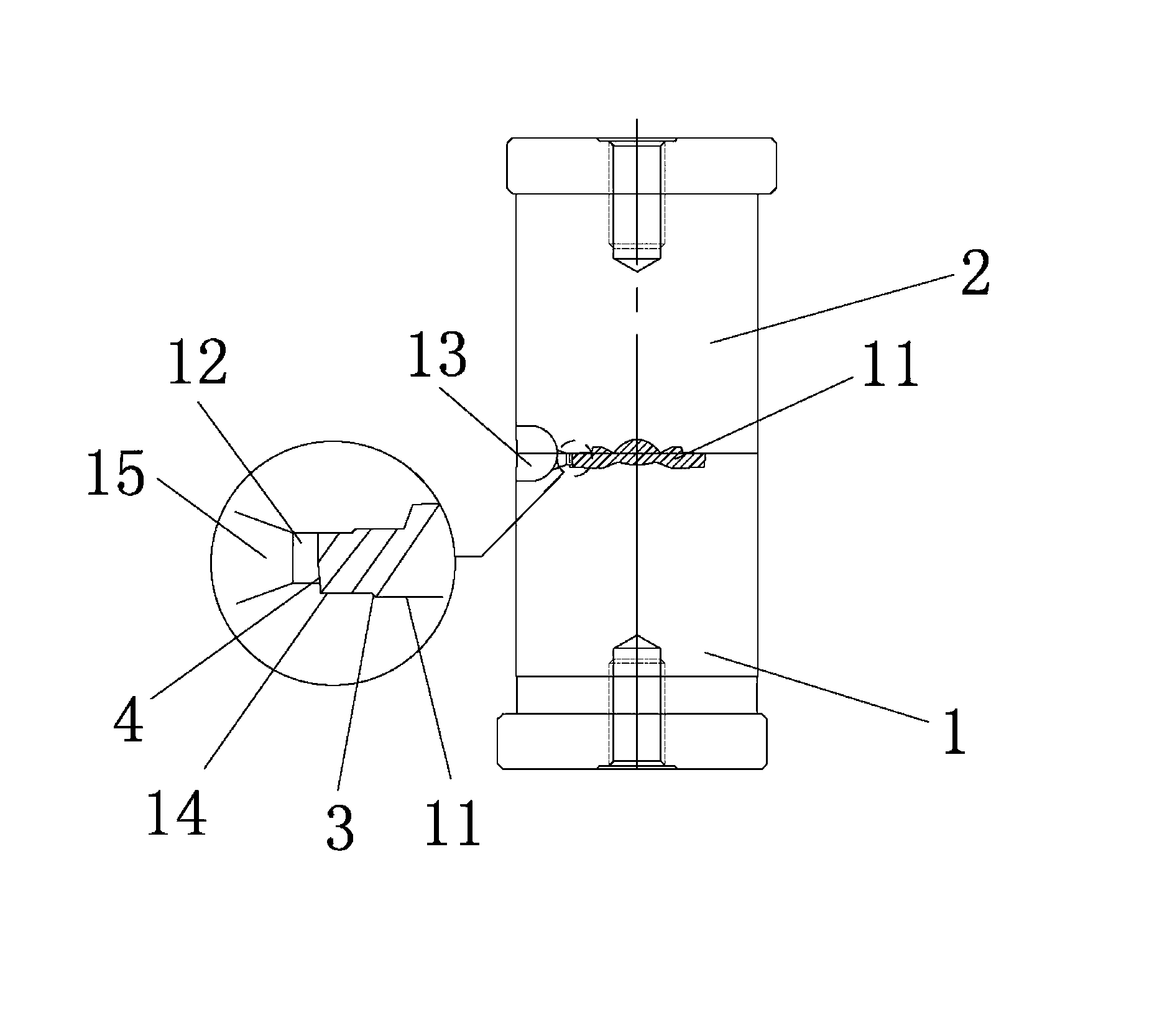

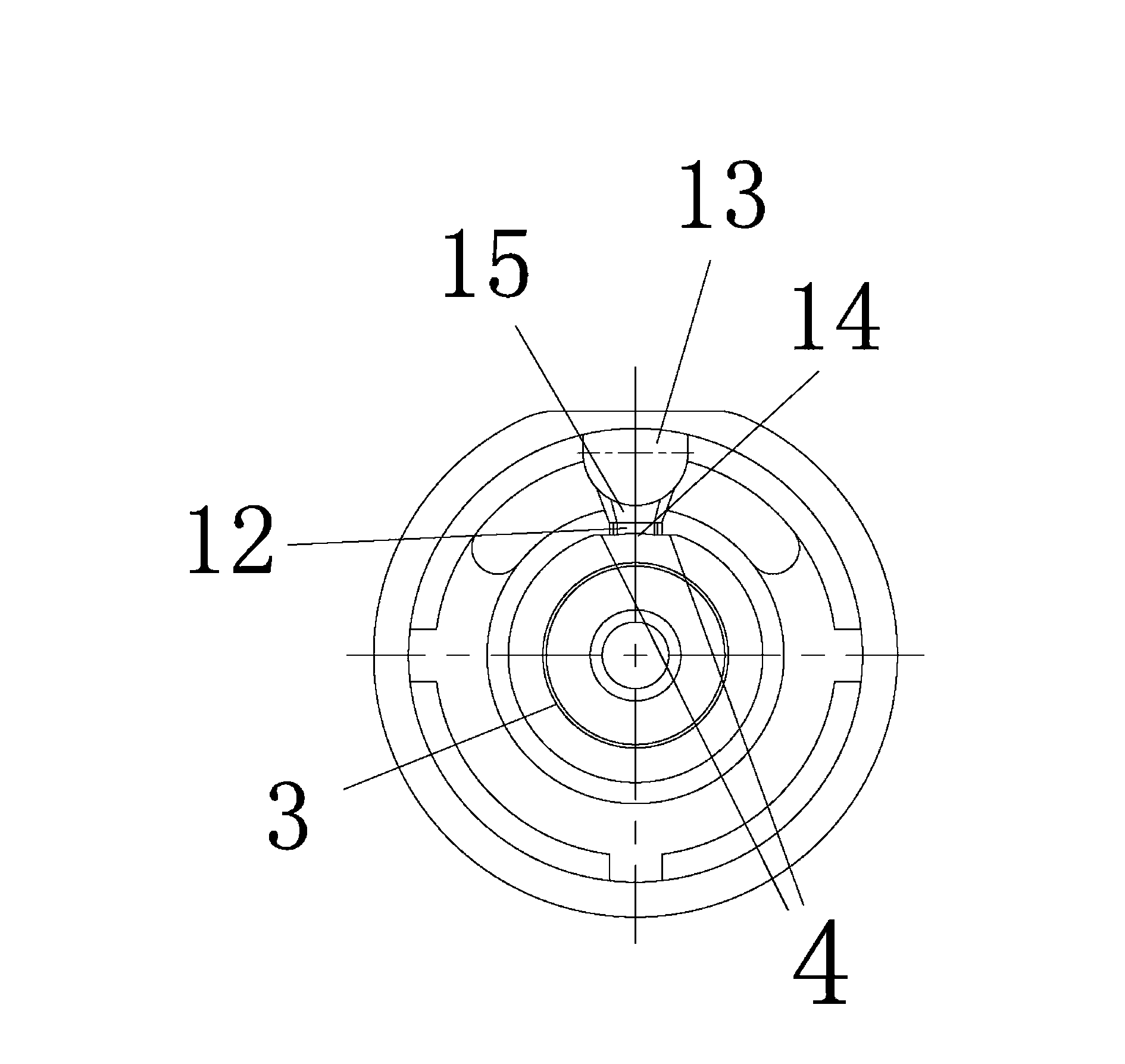

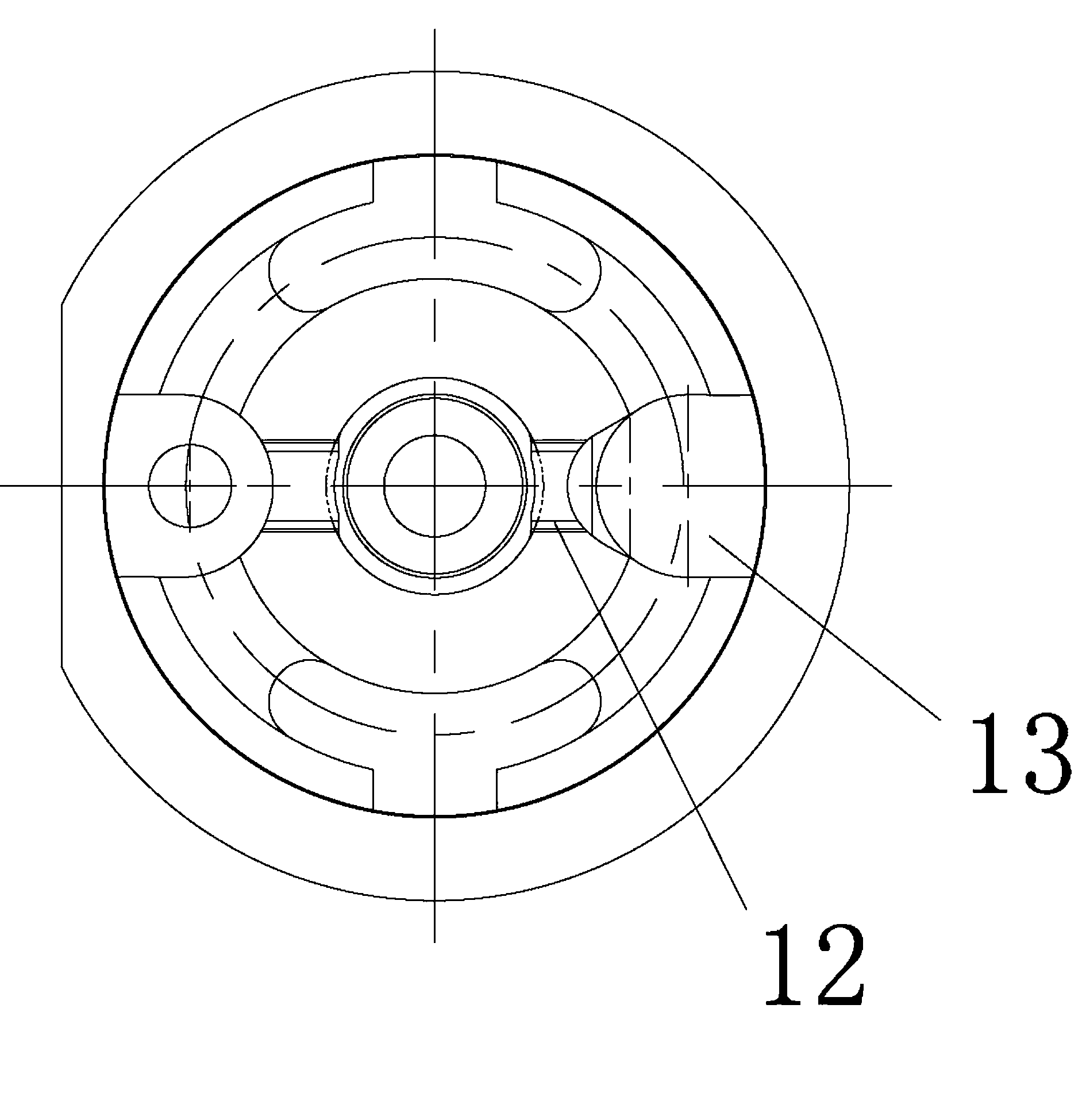

[0018] Optical lens molds, including mold cores, such as figure 1 As shown, the mold core includes a lower mold 1 and an upper mold 2, the end surface of the lower mold 1 forms a top surface, the outer edge of the top surface is surrounded by an edge, and a concave mold cavity 11 is provided in the center of the top surface. The edge of the mold cavity 11 opens a runner 12 toward the edge, and the edge is provided with a gate 13 toward the runner 12, and the intersection edge of the mold cavity 11 and the runner 12 1. A cut-off area 14 is formed between the side walls of the cavity 11 near the two sides of the runner 12, and a connecting channel 15 is connected between the runner 12 and the gate 13; the bottom surface of the cut-off area 14 is connected to the The bottom surface of the mold cavity 11 forms a step 3 at the intersection, and at the step 3 , the level of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com