Laser transmission connection double-face clamping device

A technology of laser transmission and clamping device, which is applied in the field of laser transmission welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

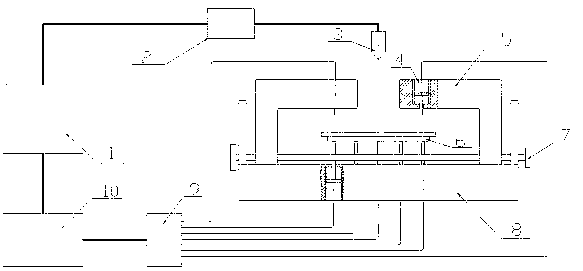

[0017] The device of the present invention will be further described in detail below in combination with schematic diagrams.

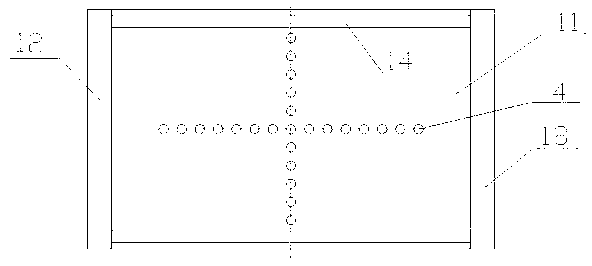

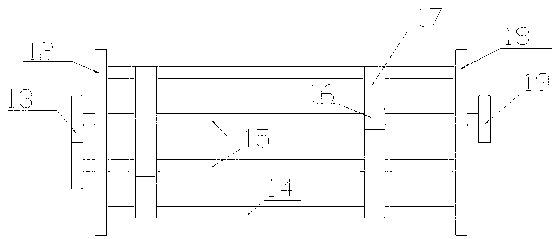

[0018] A double-sided clamping device for laser transmission welding, including an upper platen assembly 5, a small hydraulic thimble assembly 4, a handwheel adjustment mechanism 7, a lower base plate assembly 8 and a laser head 3. The upper platen assembly 5 is composed of two L-shaped platens 17, wherein the distance between the L-shaped platens can be adjusted by the adjustment hand wheel 7, so it can be flexibly applied to workpieces of various specifications, and the adjustment of the distance can not block the optical path. Each of the L-shaped pressing plates has a row of countersunk through holes, and the small hydraulic thimble assembly 4 is placed in the hole, and the thimble rod is extended and retracted under the control of the hydraulic control system 9 .

[0019] The hydraulic small thimble assembly 4 is composed of a thimble rod, a pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com