Real-time measuring device and method capable of measuring dynamic oil membrane pressure distribution and temperature of tilting-pad sliding bearings

A sliding bearing and oil film pressure technology, which is used in measuring devices, fluid pressure measurement by changing ohmic resistance, thermometers, etc., can solve problems such as difficulty in using tilting pad sliding bearings, inability to obtain accurate oil film pressure values in real time, constraints and other problems , to achieve the effect of great originality and application value, low cost, stable and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

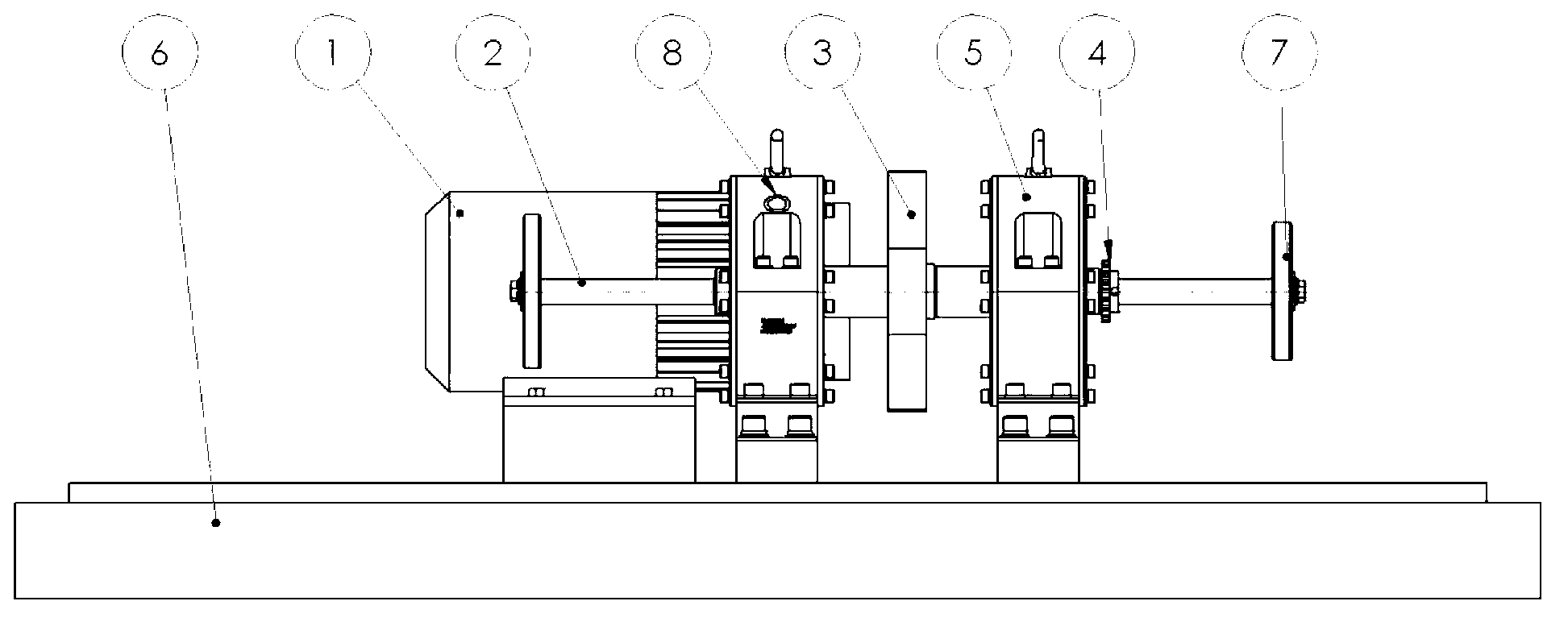

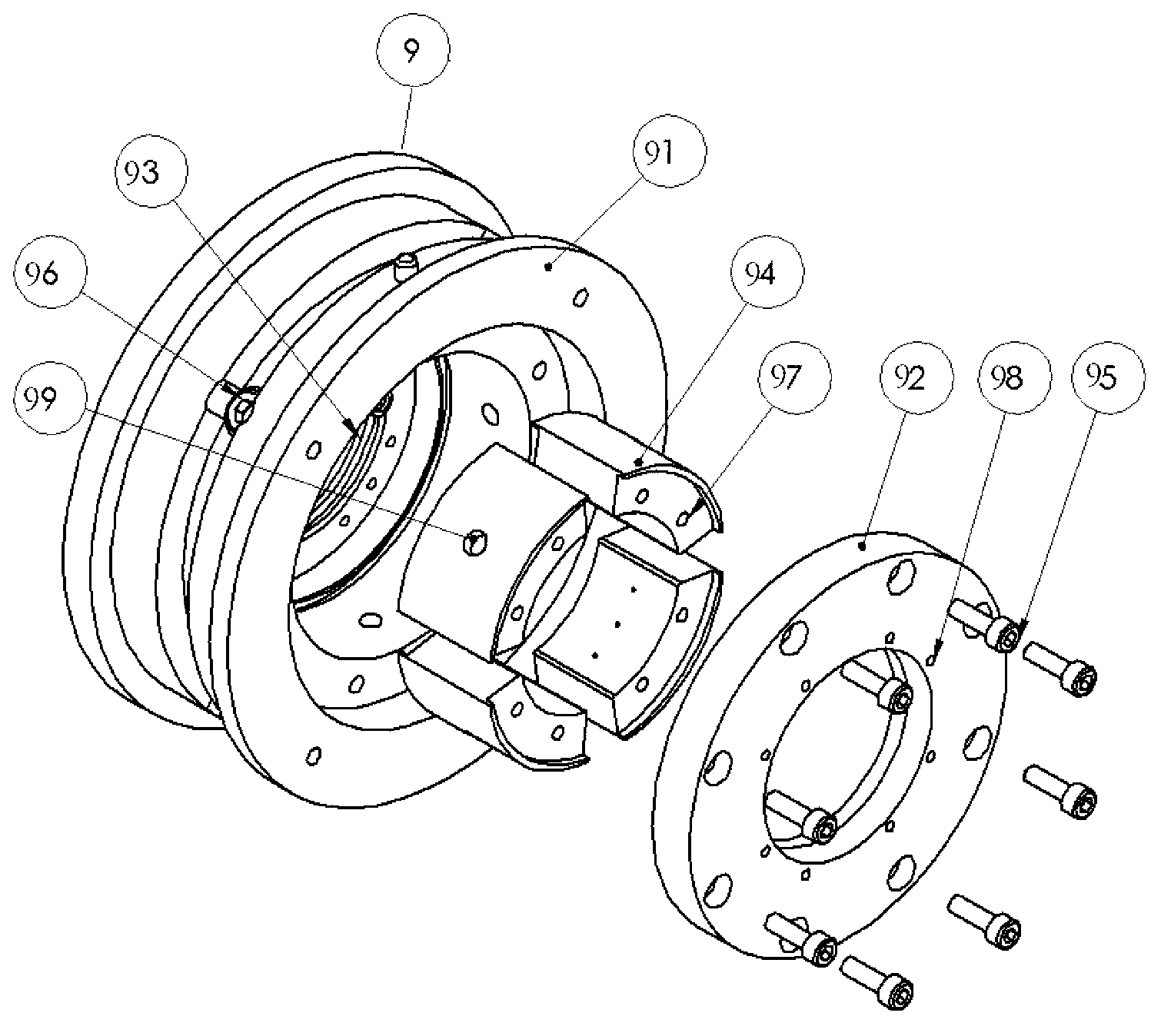

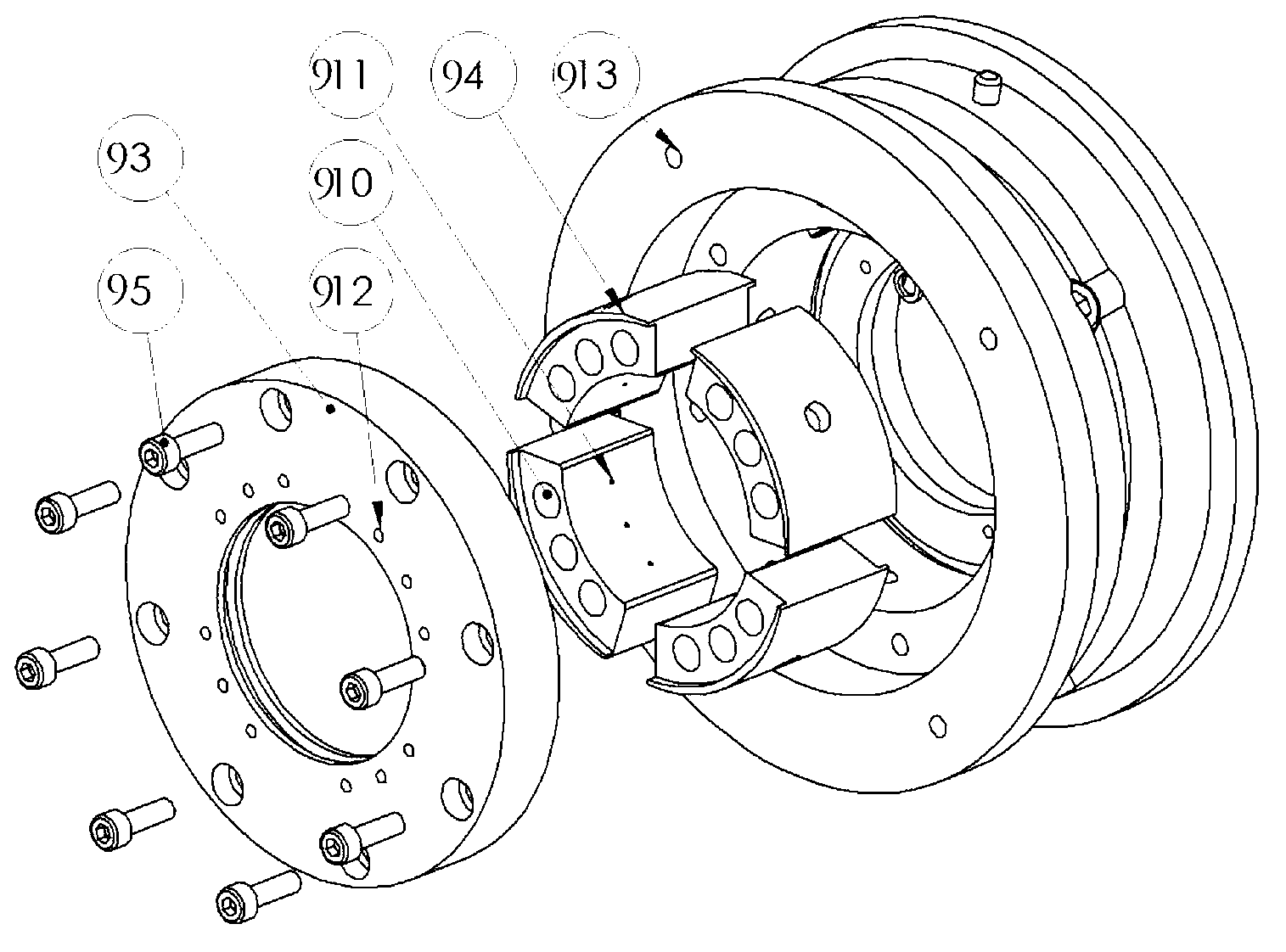

[0035] as attached figure 1 to attach Figure 6 As shown, the present invention includes: a motor 1, a transmission wheel, a main shaft 2, a key phase wheel 4, a turntable 7, a bearing seat 5, a base 6 and at least one oil supply device, the motor and the bearing seat are installed on the base, and the motor It is used to provide the power required by the measuring equipment. The output end of the motor is connected to the transmission wheel. The transmission wheel is used to transmit the power of the motor to the main shaft. The main shaft is connected to the motor through the transmission wheel. The transmission wheel is a pulley 3. One, the main shaft crosses the bearing seat, the key phase wheel and the turntable are installed on the main shaft, the key phase wheel is used to monitor the phase and speed of the main shaft, and the turntable is installed at b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com