Connecting method of inspecting lines of metal bipolar plate fuel cell stack

A technology of fuel cell stacks and metal bipolar plates, which is applied in the direction of fuel cells, fuel cell groups, circuits, etc. It can solve the problems of difficult access of welding tools, difficulty of re-welding, and falling off of solder joints. Stacking is convenient and fast, the connection method is safe and reliable, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

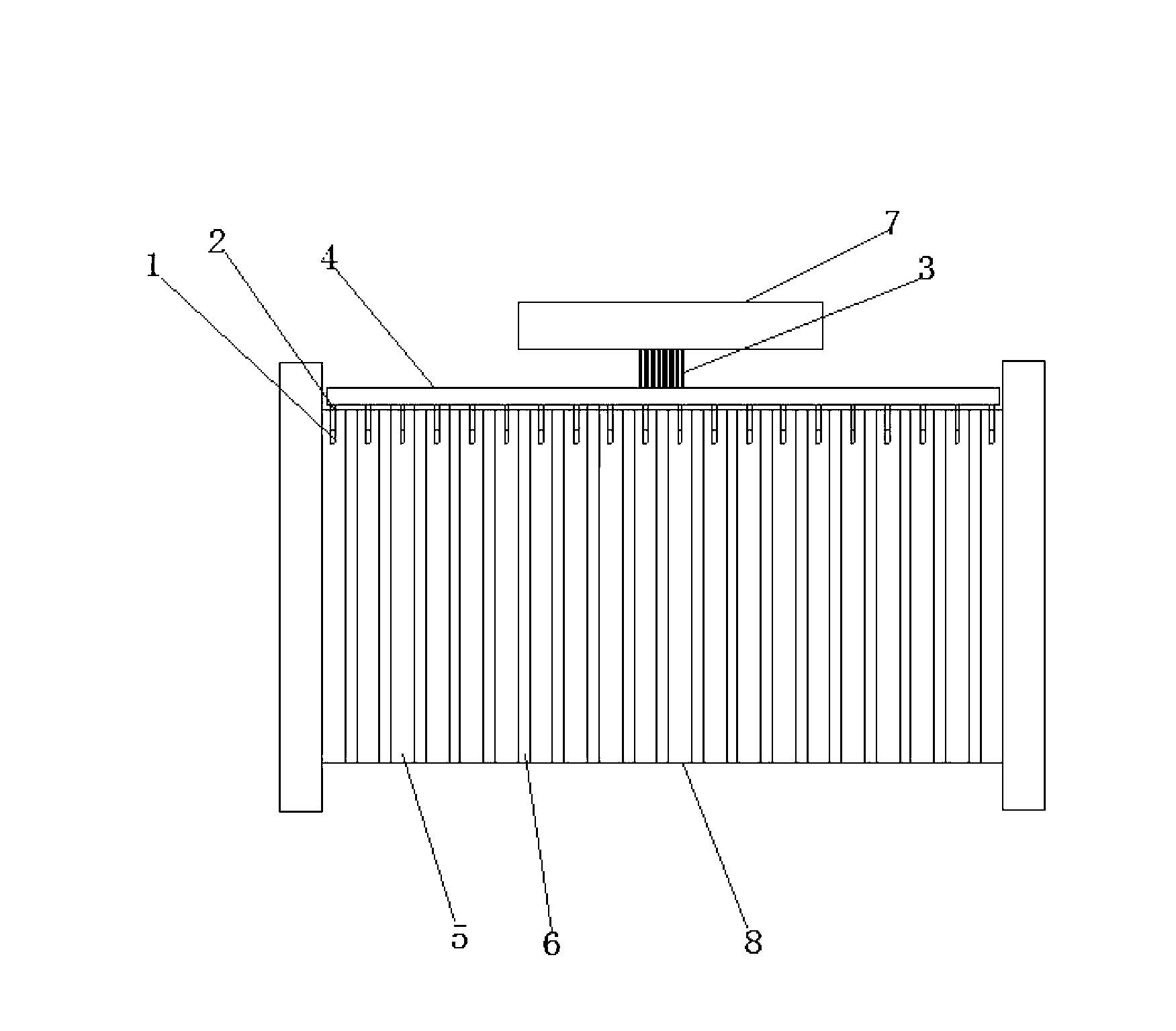

[0016] Such as figure 1 , figure 2 with image 3 The method for connecting a metal bipolar plate fuel cell stack inspection line includes the following steps:

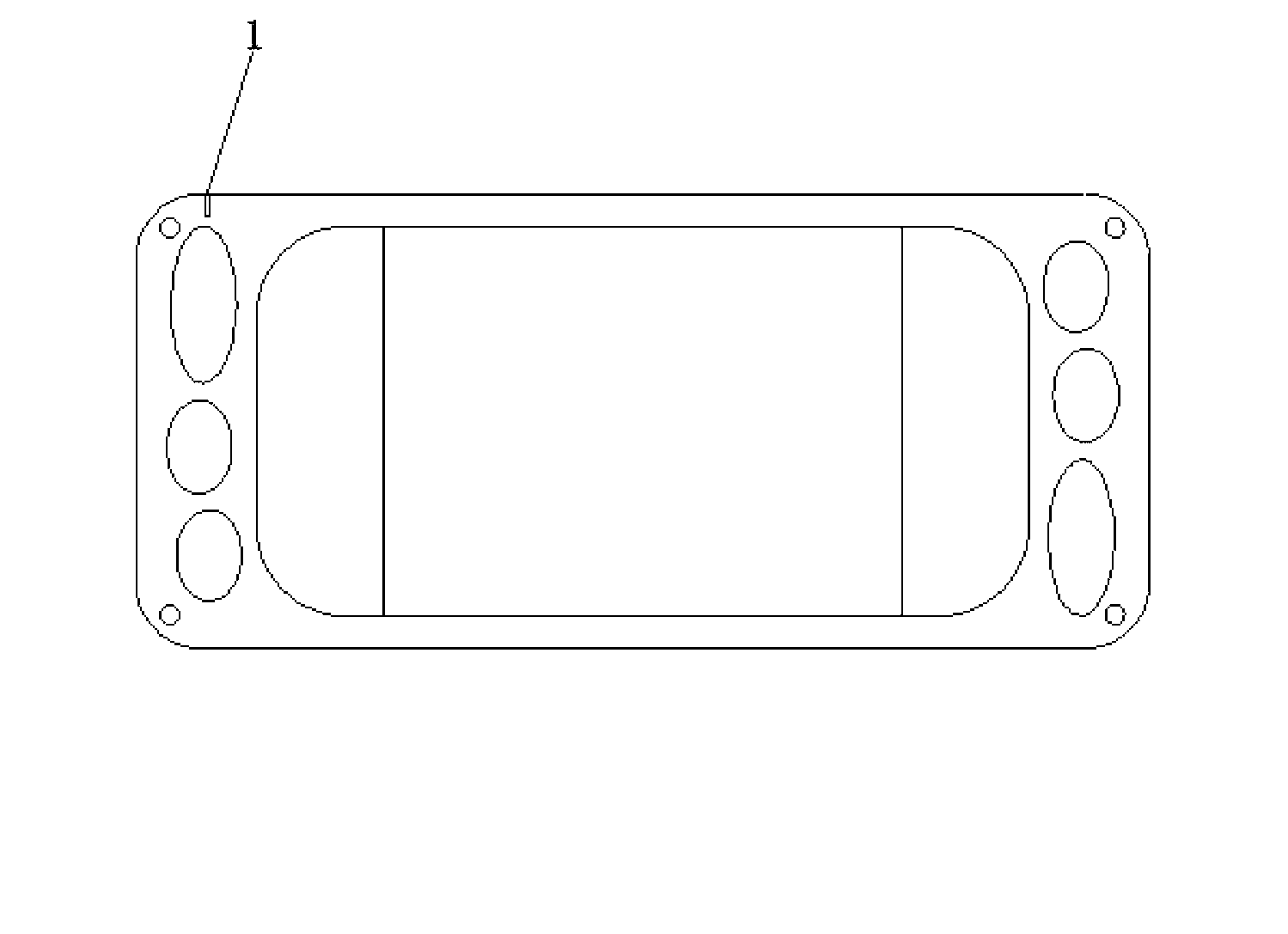

[0017] Step 1: forming a metal bipolar plate 5 with an inspection socket 1 by punching a sheet metal, and using the metal bipolar plate 5 to assemble a fuel cell stack 8;

[0018] Step 2: Calculate the distance between adjacent inspection jacks 1 according to the thickness of the metal bipolar plate 5;

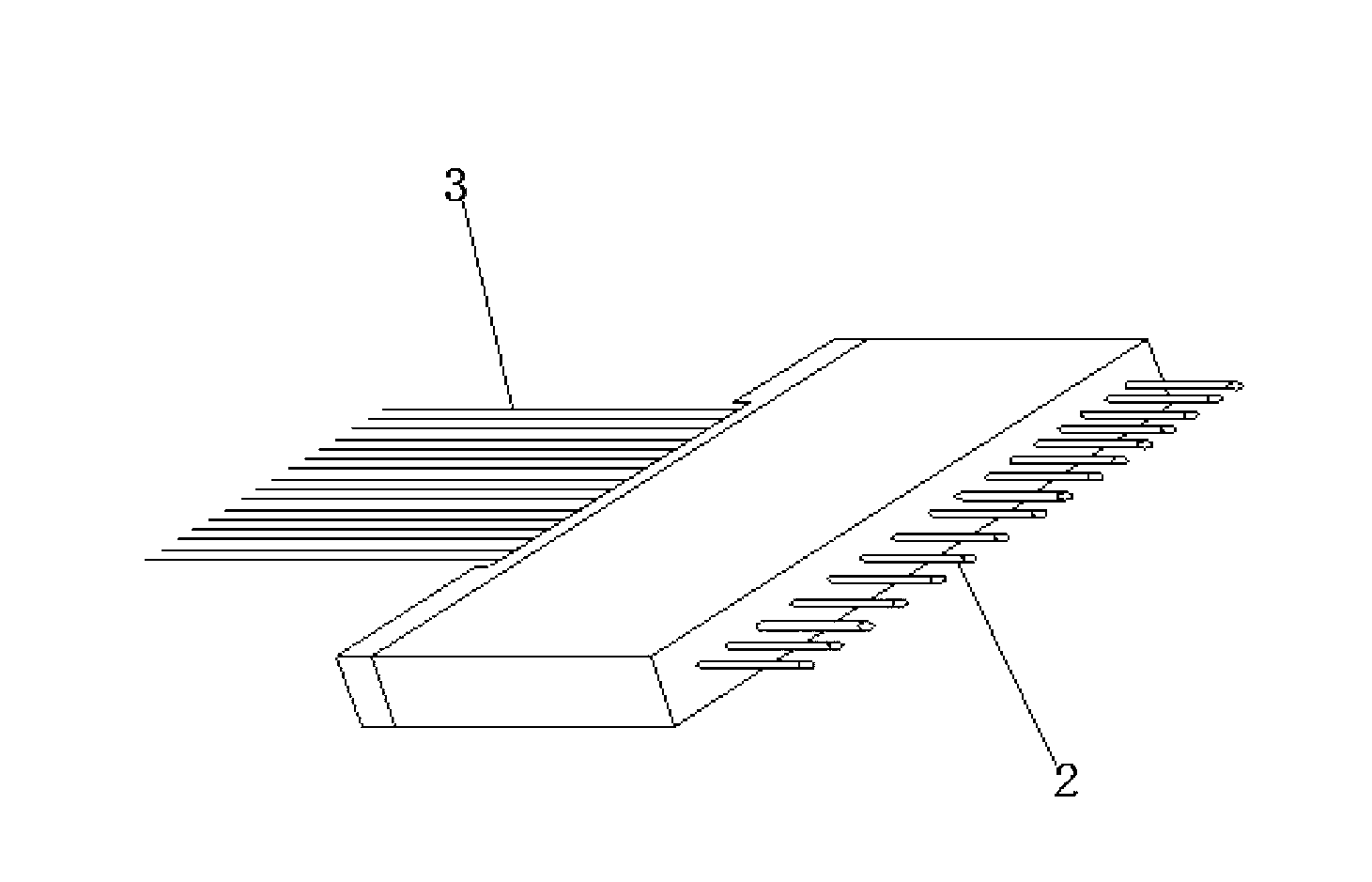

[0019] Step 3: According to the distance between the adjacent inspection sockets 1, press the cable connector 4 that matches the pin 2 and the inspection socket 1;

[0020] Step 4: insert the pin 2 of the cable connector 4 into the inspection jack 1 provided on each metal bipolar plate 5 of the fuel cell stack 8;

[0021] Step 5: Connect the cable 3 of the cable connector 4 to the battery inspection system 7 .

[0022] The metal bipolar plate fuel cell stack inspection line connection method provided by the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com