Aluminum alloy preformed armor rod cutting and transmission mechanism

A technology for cutting transmission and aluminum alloy, which is applied in the direction of transmission, mechanical equipment, belt/chain/gear, etc., can solve the problems of cutting length error, spring fatigue, high processing cost, etc., to reduce gap and cumulative error, and manufacture The effect of simple parts and stable motion rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

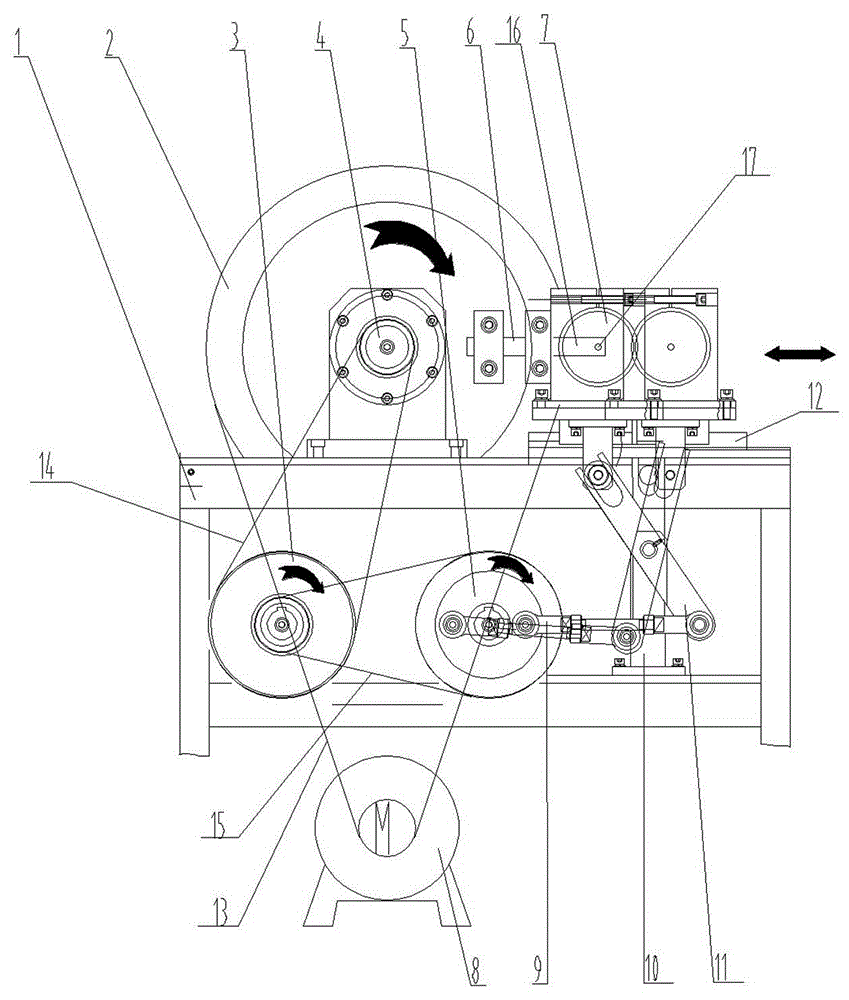

[0026] refer to figure 1 , the aluminum alloy pre-twisted wire cutting transmission mechanism includes frame 1, flywheel 2, synchronous pulley 3, flywheel main shaft 4, eccentric shaft disk 5, cutter 6, moving knife rest 7, motor 8, adjustment connecting rod 9, rocker arm Support 10 and rocker arm 11.

[0027] The flywheel main shaft 4 is installed on the upper part of the frame 1 through the bearing seat, the flywheel 2 is installed on the flywheel main shaft 4, the movable knife rest 7 is installed on the sliding guide rail 12 on the upper part of the frame 1 on one side of the flywheel 2, and the movable cutting blade 6 is fixedly installed on the flywheel 2 one side, the fixed cutting blade 16 is fixedly installed on the movable knife rest 7, the synchronous belt pulley 3, the eccentric shaft disk 5, the rocker support 10 are installed in the middle of the frame 1, and the motor 8 is installed in the bottom of the frame 1. Adjusting connecting rod 9 is housed on the ecce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com