Preparation technology of modified asphalt by adding stabilizer at later stage

A technology of modified asphalt and preparation process, applied in building components, building insulation materials, buildings, etc., can solve the problems of discontinuous production, residue, low softening point, etc., and achieve the improvement of equipment operation stability and the shortening of stabilization time. , the effect of improved operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

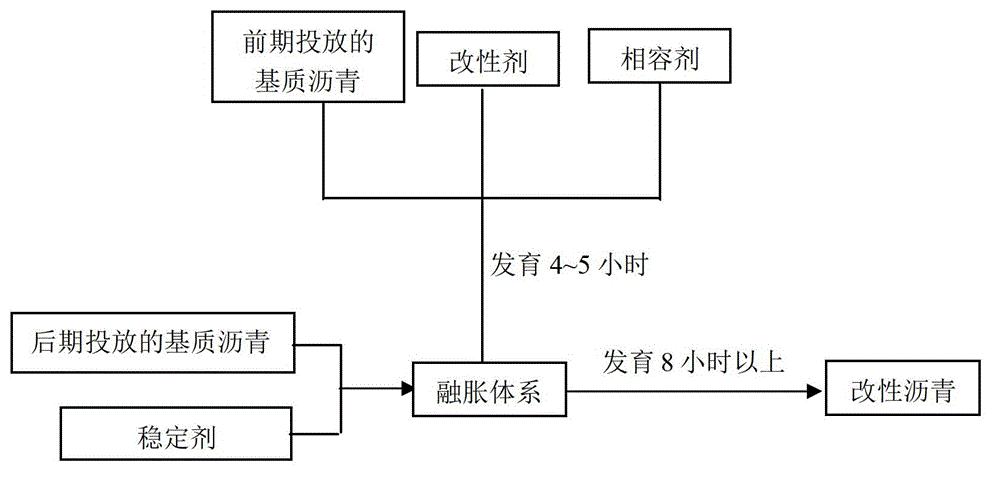

Method used

Image

Examples

Embodiment Construction

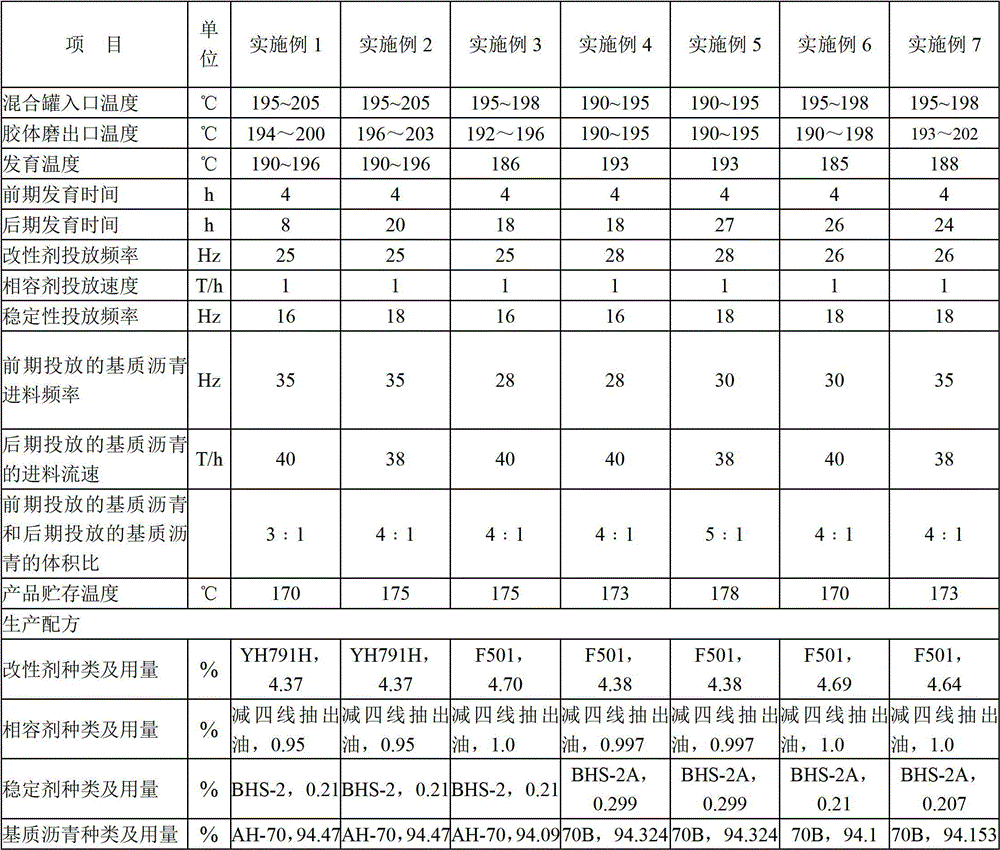

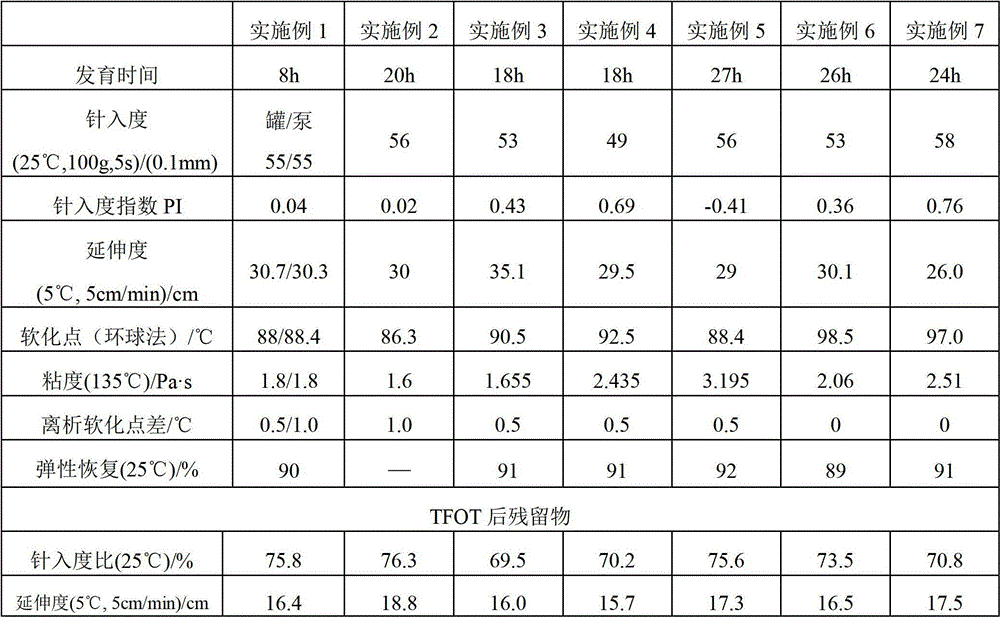

[0022] The content of the present invention is described in more detail below by the examples, but the following examples are only used to set forth the content of the present invention, rather than limiting, so any changes within the meaning and scope equivalent to the claims of the present invention, should be considered to be included in the scope of the claims.

[0023] In the following examples, a complete set of modified asphalt equipment from Dawes of the United States is used, and the production speed is about 25 tons / hour. Raise the temperature of the oil at the outlet of the heat conduction furnace to 220°C, and when the temperature of the base asphalt is heated to 200±5°C, the base asphalt is divided into two parts, most of the base asphalt is used as the base asphalt put in earlier, and the remaining base asphalt is used as The base asphalt introduced in the later period, among them, the base asphalt, modifier and compatibilizer introduced in the earlier period are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com