Multi-hole cell culture dish structure

A cell culture, bottom surface technology, applied in tissue cell/virus culture devices, biochemical instruments, biochemical equipment and methods, etc., can solve the problems of low efficiency, long operation time, increase equipment cost, etc., to achieve high efficiency and operation. The effect of short time and equipment cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

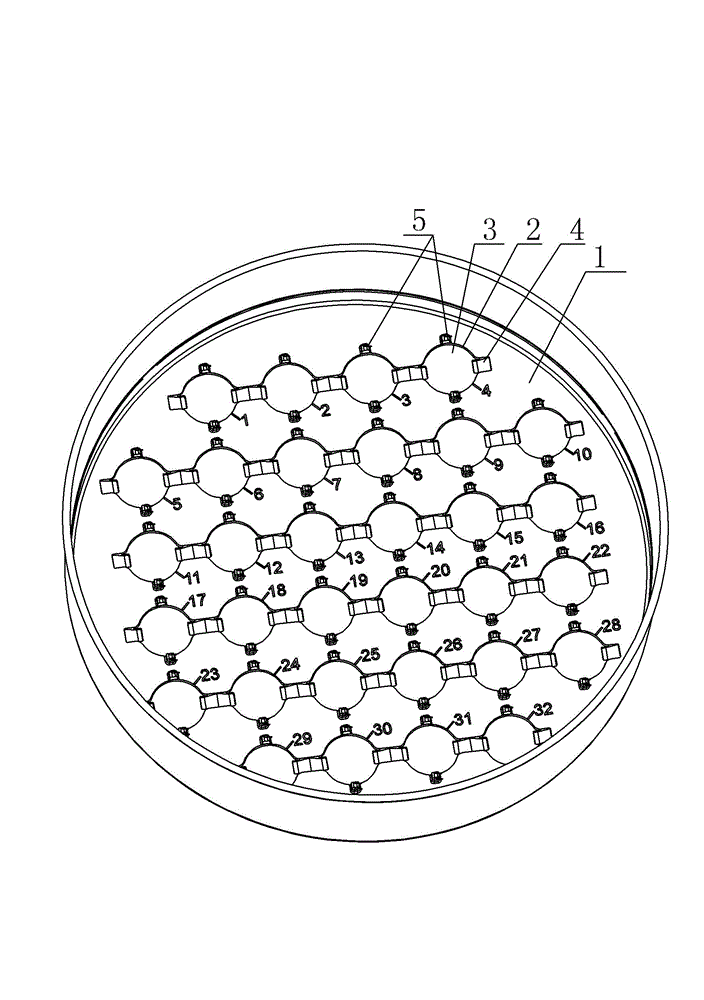

[0007] See figure 1 , which includes a cell culture dish 1, uniformly distributed small hole grooves 2 are arranged on the bottom surface of the cell culture dish 1, the glass slide 3 is correspondingly placed in the small hole groove 2, and the adjacent position of the small hole groove 2 is provided with The two sides of the single diameter of the strip groove 4 and the small hole groove 2 are provided with pillars 5, the pillars 5 are hot-melt materials, and the corresponding positions of each small hole groove 2 are marked with different numbers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com