Sand blocking type corrugated pipe expansion joint for hydroelectric power station

A technology for bellows and hydropower stations, which is applied to expansion compensation devices for pipelines, pipe elements, pipes/pipe joints/fittings, etc., and can solve the problems of removing the guide tube, shutting down water, large bellows expansion joints, and maintenance operations Difficulty and other problems, to achieve the effect of long service life, convenient production and installation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

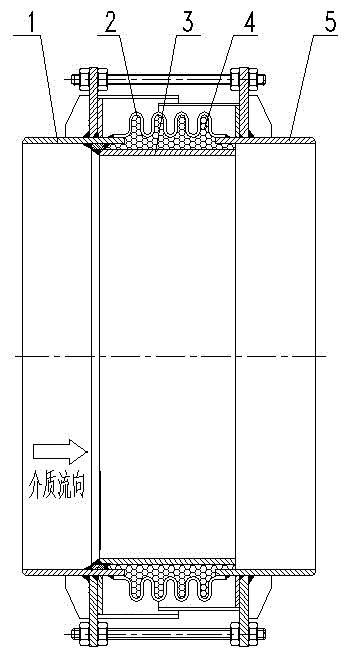

[0008] Such as figure 1 As shown, it is a sand-blocking bellows expansion joint for a hydropower station, including a bellows 2 and a guide tube 3, the bellows 2 is set on the guide tube 3, one end of the bellows 2 is welded to the upstream steel pipe 1, and the bellows 2 The other end is welded to the downstream steel pipe 5 , one end of the guide tube 3 is welded to the upstream steel tube 1 , and an elastic packing 4 is arranged between the guide tube 2 and the bellows 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com