Air heating furnace system for supplying heat to seedling greenhouse

A hot blast stove and heating technology, which is applied in the field of hot blast stove system for heating of nursery greenhouses, can solve the problems of high hot blast temperature, uneven hot blast transportation, low heat exchange efficiency, etc., and achieves increased heat exchange area, small horizontal cross-sectional area, Enhance the effect of disturbance and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

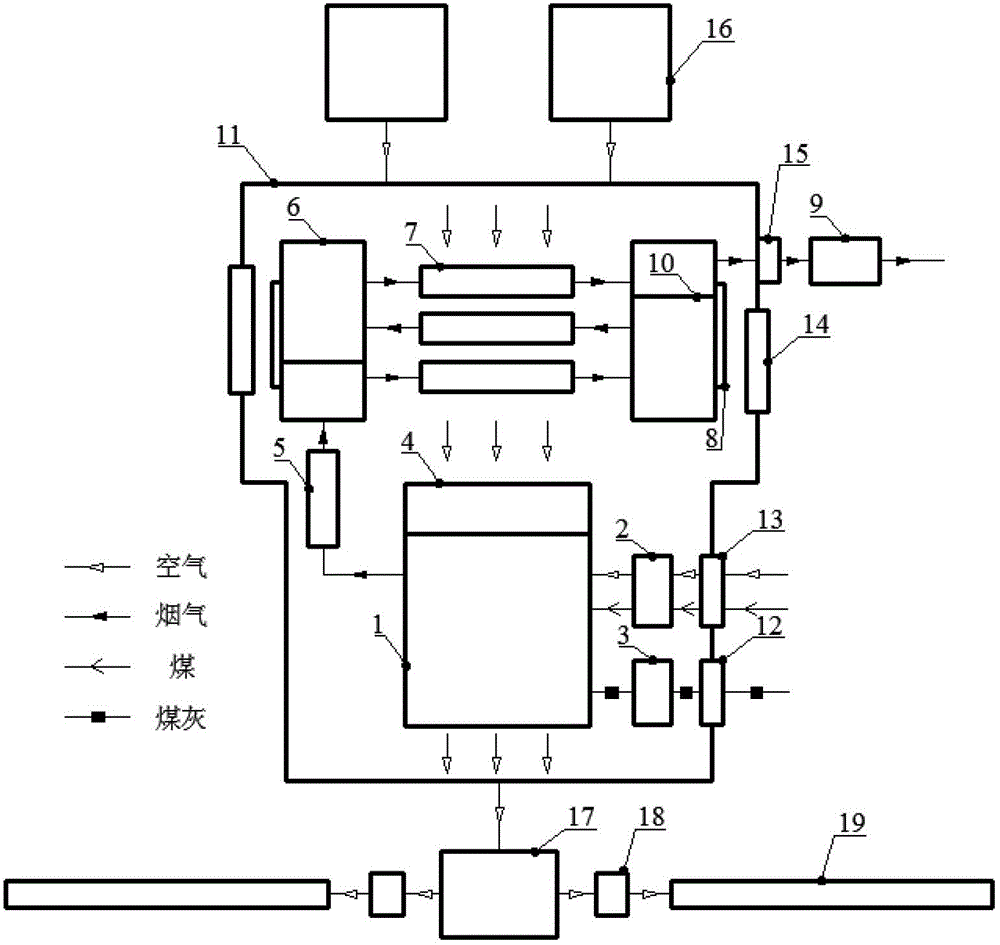

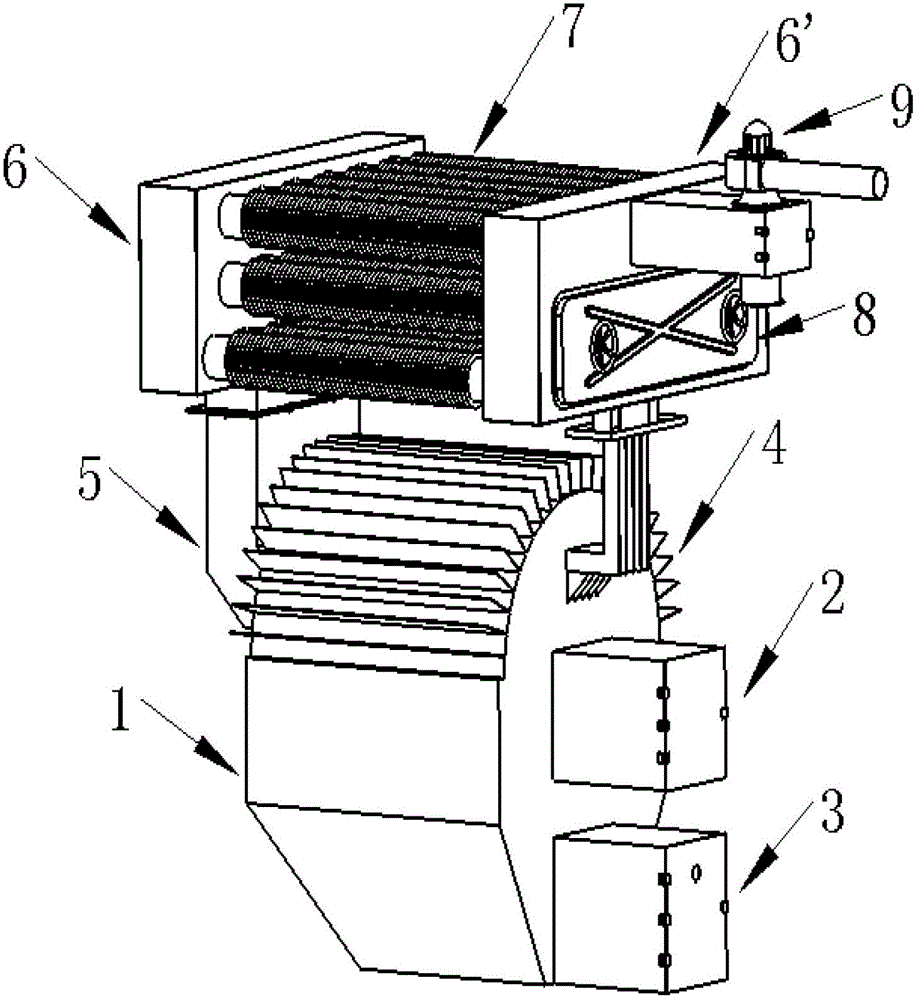

[0023] Such as Figures 1 to 4 As shown, the hot blast stove system for heating the seedling growing greenhouse of the present invention includes a combustion chamber, a heat exchanger, a heat exchange cover and a hot blast pipe 19 .

[0024] The combustion chamber includes a combustion chamber body 1 , a coal inlet 2 , an ash removal outlet 3 , a plurality of cooling fins 4 and a vertical flue 5 .

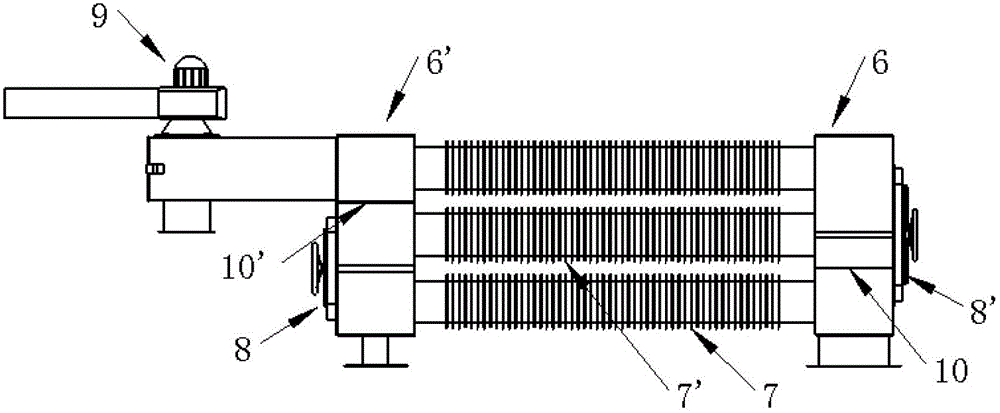

[0025] The heat exchanger includes a first header 6, a second header 6', a plurality of finned tubes 7, a dust removal door 8, a smoke exhaust fan 9 and two partitions 10.

[0026] The heat exchange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com