Step-control mechanical sampling device

A mechanical sampling and step control technology, applied in the direction of sampling devices, etc., can solve problems such as low work efficiency, no power source for sampling tools, and sample representative damage, etc., to achieve automation, improve sampling operating environment, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

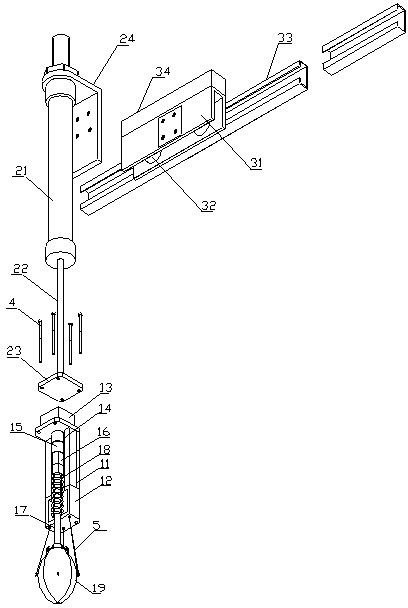

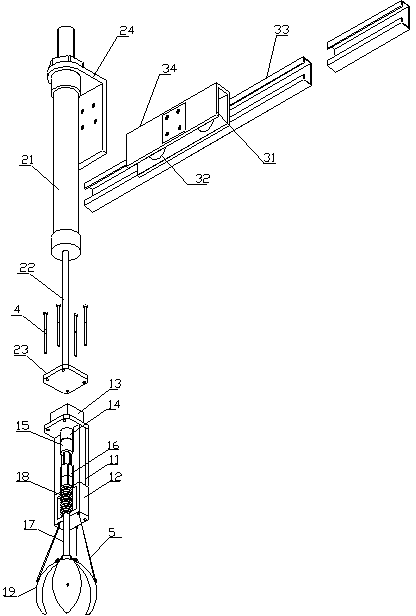

[0041] Such as Figure 1 to Figure 10 As shown, the step-controlled mechanical sampling device is composed of a structural part and a control part, and the structural part includes a sampler assembly 1, a cylinder assembly 2 and a sample delivery assembly 3;

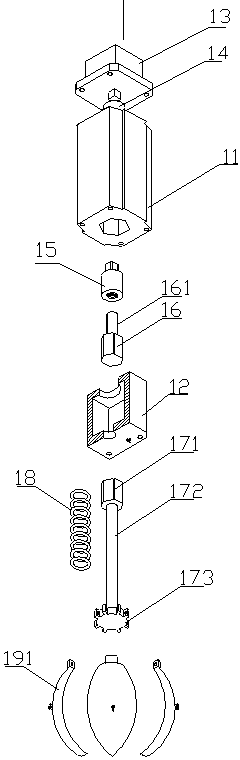

[0042] The sampler assembly 1 is composed of a transition bracket 11, a spring seat 12, a stepper motor 13, a coupling 14, a drive screw nut 15, a drive screw 16, a sampling arm 17, a spring 18 and a sampling head 19;

[0043] The transitional bracket 11 is used as the intermediate support body connecting the spring seat 12 and the stepping motor 13. Its upper part is a plane, and the upper part of the center is processed with a round hole 111 for placing the drive screw nut 15. The central lower part of the transitional bracket 11 is processed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com