A large-scale coal gas adsorption and desorption simulation test system

A simulation test system and gas technology, which is applied in the direction of fuel oil testing and material inspection products, can solve the problems of difference in results, can not reflect the desorption and adsorption characteristics of coal gas, and achieve the effect of simple experimental methods and convenient propulsion speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above objects, features and advantages more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

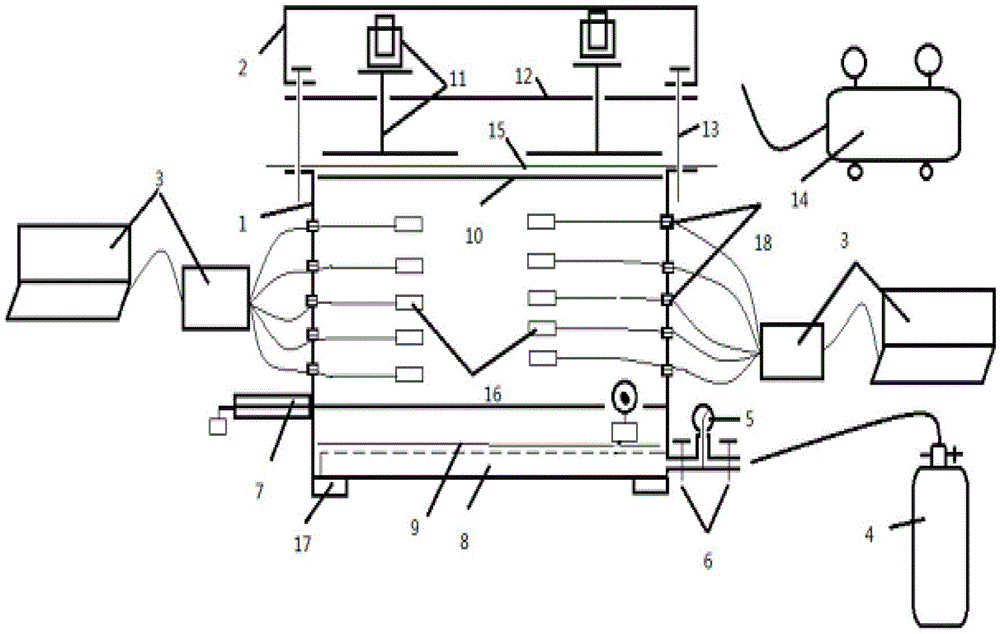

[0017] Such as figure 1 As shown, a large-scale coal gas adsorption and desorption simulation test system includes a large-scale cavity 1, a loading system 2, a gas supply system 4, a vacuum pump 14, and a gas adsorption and desorption parameter monitoring system 3; the large-scale cavity 1 consists of a An open cavity and a cover plate 12 are formed. Hollow bolts 18 are arranged on the wall of the large-scale cavity 1. The gas adsorption and desorption parameter monitoring system 3 includes a sensor 16. The sensor 16 is sealed and penetrated into the large-scale cavity 1 through the hollow bolt 18. It is also connected to the gas adsorption and desorption parameter monitoring system 3 placed outside the large-scale cavity 1; the loading system seals thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com