Low-insertion-loss coupling technique

A process method and chip technology, applied in the coupling of optical waveguides, etc., can solve the problems of hidden reliability, high price, and the accuracy of automatic search software cannot reach 100%, so as to avoid excessive loss and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

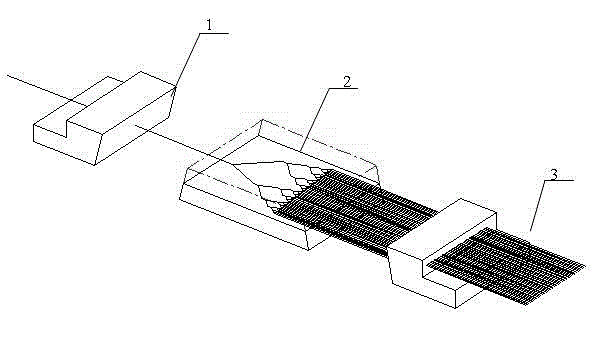

[0020] Such as figure 1 Shown:

[0021] Install the cleaned input single fiber 1 and planar waveguide chip 2 together with the fixtures on the six-dimensional adjustment frame in turn, and after finding the two side lines of the input single fiber 1 and planar waveguide chip 2 with the help of the microscopic observation system, first adjust the X axis to be parallel, and then Adjust the two sides on the Y axis to be parallel.

[0022] Turn on the light source, align the infrared light with the input single fiber 1 and the end face of the planar waveguide chip 2, hereinafter referred to as the coupling point, adjust the two light points refracted from the two ends by adjusting the knob, and then adjust the output end of the chip on the right side Place a mirror at the position, observe the corresponding channel light spot reflected by the channel at the output end of the chip, and find the brightest light spot by adjusting the coarse adjustment of the X and Y axes.

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com