SFP packaging module

A technology for encapsulating modules and sliders, which is applied in the field of optoelectronic communication, can solve the problems of poor size consistency of SFP encapsulating modules, relatively large impact on the reliability of the whole machine, and high manufacturing costs, and achieve simple structure, improved dimensional stability, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

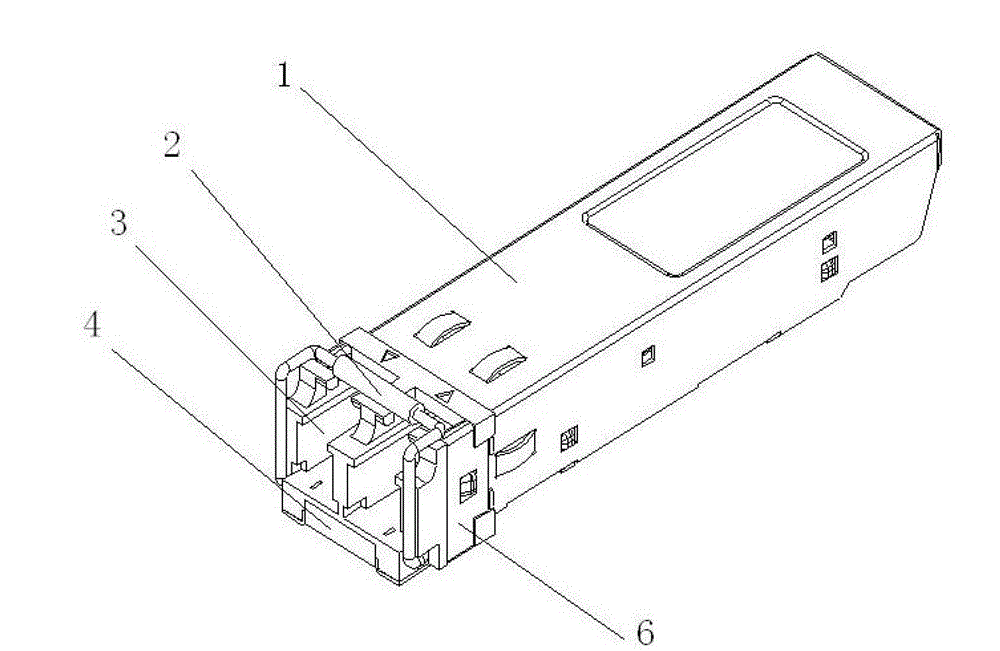

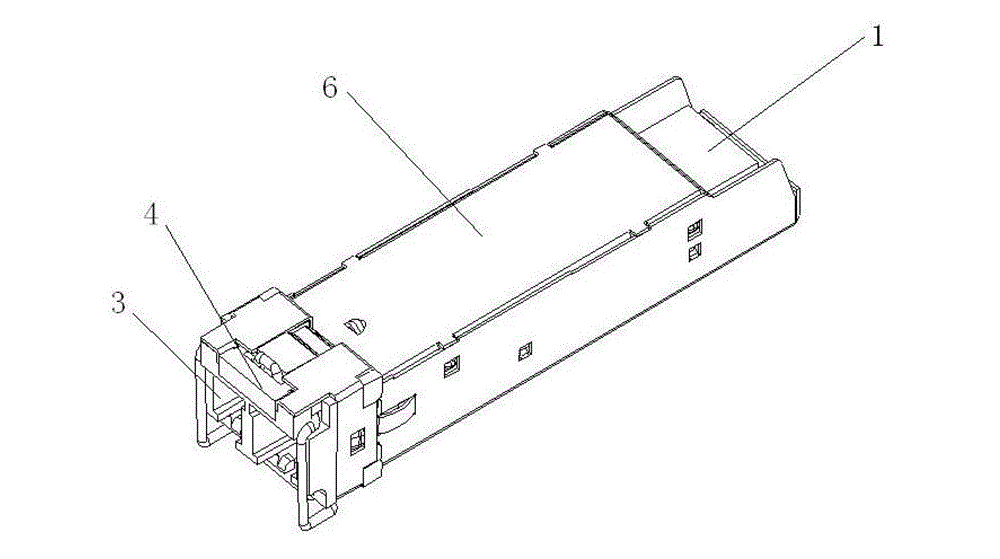

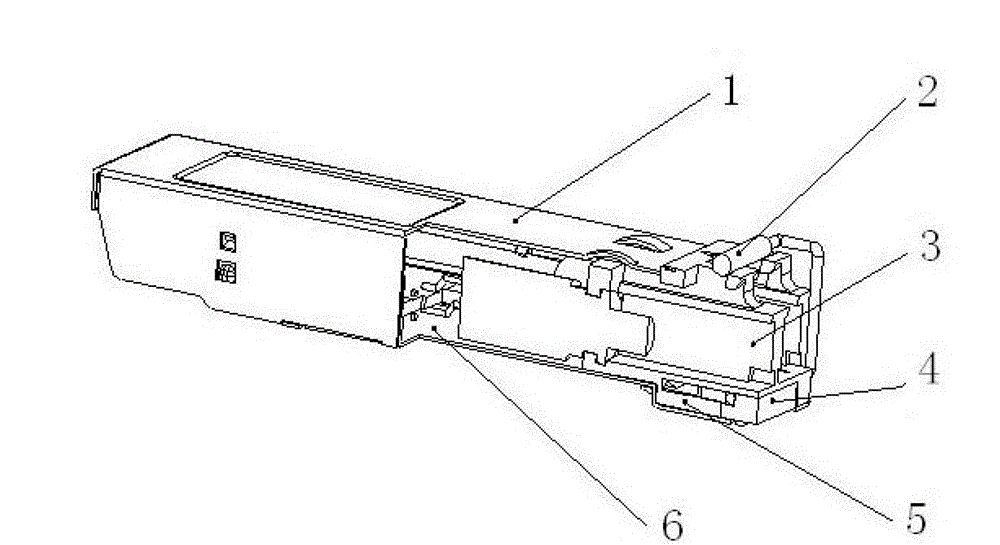

[0029] Such as Figure 1~7 As shown, the present invention mainly includes an upper cover 1 , an unlocking ring 2 , an LC connector 3 , a block 4 , an unlocking slider 5 , a base 6 and an unlocking compression spring 7 .

[0030] The base 6 includes a connection base 6-1 and a base cavity base 6-2, and the two bases 6-1 are connected to the front end of the base cavity base 6-2, and the two bases 6-1 are connected to the base cavity base 6-2 The place is step bending 6-3. The two bases 6-1 are symmetrically distributed left and right. The two bases 6-1 are provided with upper cover fixing sockets 6-4, and the upper ends of the two bases 6-1 are provided with fixed bending 6-5. The front ends of the two bases 6-1 are provided with LC connector boards 6-6. Two base fixed sockets 6-7 are symmetrically arranged on the base chamber seat 6-2, and two cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com