Automobile chassis key structural member structure optimization design method

An automotive chassis, optimization design technology, applied in computing, special data processing applications, instruments, etc., can solve the problem of not finding key structural parts of automotive chassis design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

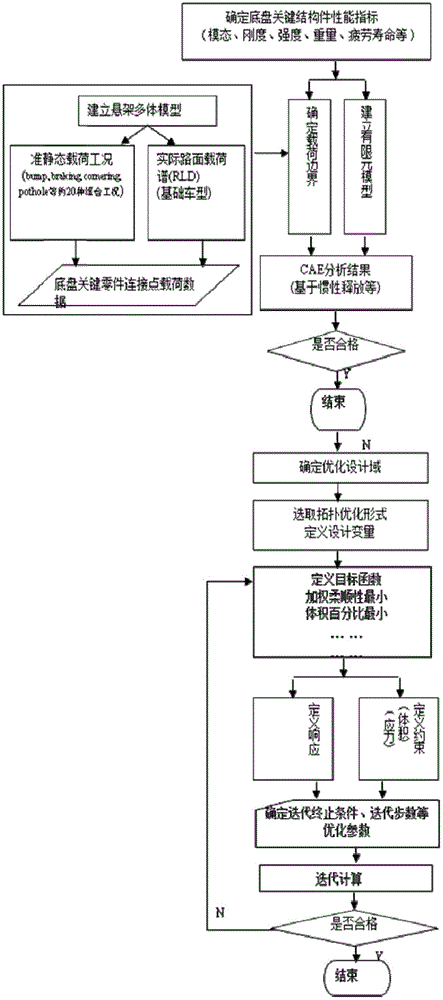

[0046] Such as figure 1 As shown, the structural optimization design method of the key structural parts of the automobile chassis of the present invention includes:

[0047] Step 1, determine the performance index of the key structural parts of the chassis;

[0048] Step 2, establish a multi-body model of the suspension, and calculate the load of each connection point of the key structural parts of the chassis;

[0049] Step 3, establishing an initial finite element design domain suitable for the topology optimization design of key structural parts of the chassis;

[0050] Step 4, establishing a topology optimization mathematical model;

[0051] Step five, iterative solution;

[0052] Step six, obtain the topology optimization design results of the key structural parts of the chassis.

[0053] The above steps will be described in detail below.

[0054] Step 1: Determine the performance indicators of the key structural parts of the chassis.

[0055]In the process of vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com