Terminal sealing system of tubular colloid lead-acid storage battery

A lead-acid battery and sealing system technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of acid creeping, leakage, difficult to seal, loose terminals, etc., to achieve convenient operation, high reliability, and sealing effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

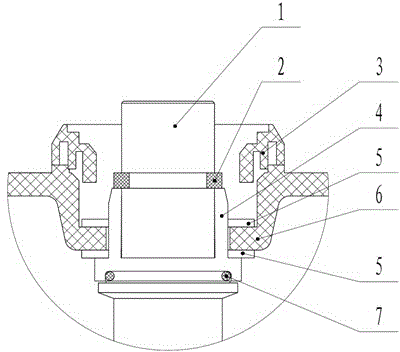

[0017] like image 3 As shown, a terminal sealing structure of a tubular colloidal lead-acid battery mainly includes a battery terminal 1, an O-shaped sealing rubber ring 7, a pressure sleeve 4, a rubber flat washer 5, a semicircular snap ring 2, an ABS engineering plastic ring 3 and a battery cover 6.

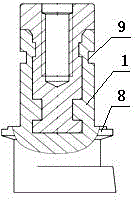

[0018] Terminal 1 is composed of a lead column and a copper core inlaid inside. There is an annular boss 8 in the middle of the lead column of terminal 1. There is an annular groove 9 near the outer circumference of the copper core of the lead column, which prolongs the acid climbing path of the battery terminal part and also It prolongs the terminal leakage time.

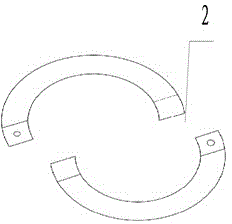

[0019] O-shaped sealing rubber ring 7, pressure sleeve 4, and semicircular snap ring 2 are sleeved on the outer periphery of the lead column. The pressure sleeve 4 tightly presses the O-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com